Screw Roofing Nail

Our commitment to maintaining strict quality control measures guarantees that our roofing screw nails meet and exceed international standards. Each iron nails for sale undergoes rigorous testing to ensure its strength, corrosion resistance, and overall reliability. We take pride in providing products that deliver exceptional performance and meet the demands of our discerning customers.

What sets us apart from our competitors is our ability to offer high-quality bulk roofing nails at a lower price point. Through efficient production processes and economies of scale, we have been able to reduce manufacturing costs and pass on the savings to our customers. We firmly believe that quality should not be compromised by price, and our types of roofing nails exemplify this ideology.

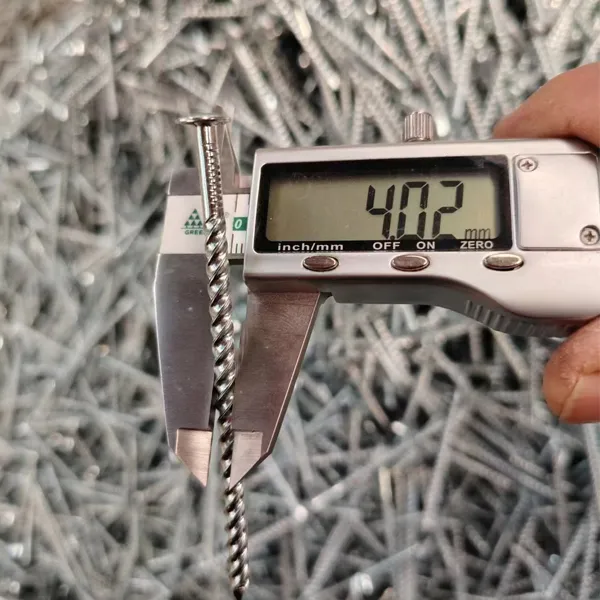

The Main Roofing Nail Size As Follows

R/screw & Washer10x100 P/WASHER:

65MMX4MM 90MMX4MM

75MMX4MM 120MMX4MM

R/SCREW & Washer Bonded

75MMX4.5MM 90MMX50MM

120MMX8MM

Roofing Nail Use

Building construction / Wooden furniture / Connect timber pieces / Asbestos shingle

Plastic tile fixed / Wooden construction / Indoor decorations / Roofing sheets

Umbrella head is designed for preventing the roofing sheets from tearing off around the head of the nail, as well as offering an artistic and decorative effect. The twist shanks and sharp points can hold wood and roofing tiles in position without slipping.

- Length is from the point to the underside of the head.

- The umbrella head is attractive and has high strength.

- Rubber/plastic washer for additional stability & adhesion.

- Twist ring shanks offer excellent withdrawal resistance.

- Various corrosion coatings for durability.

Complete styles, gauges and sizes are available.

What Is A Roofing Nail

One kind of fastener made especially for attaching roofing components, like shingles, to a roof deck is a roofing nail. In order to endure severe weather conditions and avoid rust, these nails are usually composed of galvanized steel or other metals that are resistant to corrosion. The big, flat head of roofing nails gives them a firm grip and aids in distributing stress uniformly throughout the roofing material to avoid damage.

The shaft of a roofing nail is typically smooth or slightly ridged, which helps it penetrate the roofing material and roof deck without splitting the wood. Some roofing nails are also equipped with a ringed or spiral shank, which enhances their grip and holding power, especially in high-wind areas. The length of the nail varies depending on the thickness of the roofing material, with longer nails used for thicker or multi-layered roofing systems.

Roofing nails are available in various sizes, with the most common being 1 to 1.5 inches in length. They are typically used for securing asphalt shingles, metal roofing, and other roofing materials, ensuring a secure, weather-tight roof. Proper installation of roofing nails is crucial, as incorrectly placed nails can lead to leaks, shingle blow-off, or other roofing failures.

What Are Roofing Nails Used For

Roofing nails are specialized fasteners designed specifically for securing roofing materials, such as shingles, tiles, and metal sheets, to a building’s roof structure. These nails play a critical role in ensuring the durability and stability of the roofing system, protecting the interior of the building from water damage, harsh weather conditions, and other external elements. Understanding the primary uses of roofing nails helps ensure their proper application and enhances the overall performance of the roof.

1. Securing Roofing Shingles

One of the most common uses of roofing nails is to fasten asphalt shingles to the roof deck. Roofing nails are driven through the shingles into the decking material (typically plywood or OSB) to hold the shingles in place. These nails are designed with a wide, flat head that prevents the nail from pulling through the shingle, ensuring that the shingles stay securely in place throughout their lifespan.

2. Fastening Underlayment and Felt Paper

Roofing nails are also used to secure the underlayment or felt paper that goes beneath the roofing materials. The underlayment acts as an additional layer of protection against moisture and serves as a barrier between the shingles and the roof deck. By securely fastening the underlayment with roofing nails, homeowners ensure that the roof's waterproofing layer remains intact and functional.

3. Mounting Roof Vents, Flashing, and Other Accessories

In addition to securing the main roofing materials, roofing nails are often used to fasten roof vents, flashing, and other essential roofing components. Flashing is placed around chimneys, skylights, and vents to prevent water from leaking into the roof structure. Roofing nails hold these pieces in place, ensuring that the flashing is properly sealed and does its job effectively.

4. Enhancing Roof Stability in High Winds

Roofing nails are vital in regions prone to high winds, such as coastal or storm-prone areas. When properly installed, these nails help prevent shingles and other roofing materials from being blown off during strong storms, providing enhanced roof stability.

Different Types Of Roofing Nails

Smooth Shank Roofing Nails

Smooth shank roofing nails are the most basic and commonly used type of roofing nails. These nails have a smooth shaft, which makes them easy to drive into materials, but they offer minimal holding power. Smooth shank nails are generally used for light-duty roofing jobs or in less demanding environments where maximum holding strength is not a critical factor.

Ring Shank Roofing Nails

Ring shank roofing nails have a series of rings or ridges around the shank, which provide extra grip and holding power when driven into roofing materials. These nails are ideal for securing roofing materials in areas prone to high winds or other environmental stresses. The added friction of the rings ensures the nails remain securely in place over time, making them a preferred choice for high-quality roofing installations.

Screw Shank Roofing Nails

Screw shank nails feature a threaded shaft that provides superior holding power compared to smooth and ring shank nails. The threaded design helps prevent the nails from pulling out, making them an excellent choice for installations that require extra security, such as in areas prone to high winds or heavy snow loads. Screw shank roofing nails are often used for securing heavier roofing materials like slate or clay tiles.

Cupped Head Roofing Nails

Cupped head roofing nails have a slightly concave head, which allows the nail to better hold roofing materials in place without damaging the surface. The cupped head is especially beneficial when installing shingles, as it prevents the nail from pulling through the material. These nails are commonly used for securing asphalt shingles and other soft materials.

Stainless Steel Roofing Nails

Stainless steel roofing nails are known for their resistance to corrosion, making them ideal for coastal or high-moisture environments. These nails are durable and long-lasting, even in harsh weather conditions. Stainless steel roofing nails are commonly used in marine, coastal, or high-humidity areas where standard galvanized nails may rust over time.

Aluminum Roofing Nails

Aluminum roofing nails are lightweight and resistant to corrosion, making them a popular choice for specific roofing applications, particularly in residential roofing. They are less prone to rusting than steel nails and can be a cost-effective option when dealing with mild environmental conditions.

How to Choose the Right Roofing Screw Nails for Different Roofing Materials

When selecting roofing screw nails, it’s important to choose the right type to ensure a secure and durable connection, regardless of the roofing material. The correct fastener enhances the roof’s integrity and prevents leaks, ensuring longevity and protection from the elements. Here’s a guide on how to choose the right roofing screw nails for various roofing materials.

1. Asphalt Shingles

For asphalt shingles, roofing screw nails with a large, flat head and a strong, corrosion-resistant coating are ideal. Stainless steel or galvanized nails are commonly used for asphalt roofs because they prevent rust and maintain their holding strength under various weather conditions. Additionally, self-drilling roofing screw nails are often preferred because they make the installation process easier, especially when working with multiple layers of shingles.

2. Metal Roofing

When installing metal roofing, the nails used must have a strong, rust-resistant coating, like galvanized or coated steel, to withstand exposure to rain and humidity. Self-tapping roofing screws with a rubber washer are essential for metal roofs to ensure a water-tight seal. The rubber washer helps prevent leaks around the screw hole, which can be a major issue in metal roofing installations.

3. Wooden Roof Decks

For wooden roof decks, roofing screw nails should be designed to penetrate deep into the wood and create a strong bond. It’s crucial to select nails that are made from corrosion-resistant materials like stainless steel, particularly if the roof will be exposed to moisture or coastal environments. The size and length of the nail are also important — a longer nail will provide better hold, ensuring that the shingles stay securely in place.

4. Tile Roofing

Tile roofs require roofing screw nails that are sturdy and capable of holding the weight of the tiles. Brass or stainless steel nails are the best options for tile roofing, as they won’t rust and will withstand the additional weight of the tiles. Also, consider nails with a low-profile head to avoid damaging or cracking the tiles during installation.

Screw Roofing Nails vs. Regular Roofing Nails: Unveiling the Performance Gaps

When it comes to securing your roof, the choice between screw roofing nails and regular roofing nails can significantly impact durability and functionality. Here’s a breakdown of their performance differences, tailored for builders seeking reliable nails and screws for sale.

1. Holding Power: Threaded Shanks vs. Smooth/Ringed Shanks

Screw roofing nails feature a threaded shank design, offering unmatched withdrawal resistance compared to regular types of roofing nails with smooth or ringed shanks. This structure creates a stronger grip in materials like wood, metal, or tile—ideal for high-wind areas or heavy roofing materials. Regular nails, while suitable for light-duty tasks, may loosen over time, risking shingle blow-off.

2. Installation Efficiency: Self-Drilling vs. Traditional Driving

Screw nails with self-drilling tips simplify installation, especially in multi-layered roofs. This design reduces labor for projects like metal roofing, where precision matters. Regular nails require careful driving to avoid damage, making them less efficient for complex jobs.

3. Corrosion Resistance: Coatings for Longevity

Many screw nails come in stainless steel or advanced galvanized coatings, perfect for coastal areas. For metal roofing nails, rubber washers create a watertight seal—critical for preventing leaks. Regular nails, especially basic types, corrode faster in harsh weather.

4. Versatility Across Roofing Materials

Screw nails excel in heavy-duty use:

Metal roofing: Self-tapping screws with washers ensure a leak-proof fit.

Tile roofing: Their strength supports tile weight without cracking.

Wooden decks: Deep penetration prevents slipping.

Regular nails suit lightweight tasks like asphalt shingles but lack robustness for demanding materials.

Why Choose YISIZHE as Your Roofing Nail Supplier?

As a trusted roofing nail supplier, YISIZHE offers premium types of roofing nails—from screw nails to metal roofing nails—tested for strength and corrosion resistance. Our bulk solutions balance quality and cost, whether for commercial projects or residential roofs. Upgrade to screw nails for lasting performance—explore our nails and screws for sale today.

Five Technical Features of Screw Roofing Nails: Engineered for Superior Roofing Performance

Screw roofing nails stand out among types of roofing nails for their innovative design and durability. Here’s a deep dive into their five key technical features, tailored for builders seeking reliable nails and screws for sale.

1. Threaded Shank Design: Unmatched Withdrawal Resistance

The core of screw roofing nails lies in their threaded shank, which creates a mechanical lock in materials like wood, metal, or tile. Unlike smooth shank roofing nails, the spiral threads provide 300%+ better holding power, making them ideal for high-wind zones or heavy roofing materials. This design reduces the risk of shingle blow-off, a critical advantage for coastal or storm-prone areas.

2. Corrosion-Resistant Materials & Coatings

Premium screw nails from YISIZHE feature stainless steel or advanced galvanized coatings, ensuring longevity in harsh environments. For metal roofing nails, the corrosion-resistant finish prevents rust even in high-moisture zones, outperforming standard nails. These coatings meet international standards, making them a top choice for roofing nail supplier clients.

3. Self-Drilling/Tapping Tip: Effortless Installation

Many screw roofing nails come with a self-drilling tip, eliminating the need for pre-drilling in dense materials. This feature speeds up installation in projects like metal roofing, where precision and efficiency matter. The tip’s design reduces labor costs and minimizes material damage, a key benefit for contractors.

4. Integrated Washer System: Watertight Sealing

A rubber or plastic washer beneath the nail head creates a waterproof barrier—vital for preventing leaks in metal roofing or underlayment installations. Unlike regular nails, this design ensures a tight seal, even in heavy rain, making screw nails the go-to choice for moisture-sensitive areas.

5. Versatile Sizing & Load-Bearing Capacity

Screw roofing nails come in diverse lengths (65mm–120mm) and shank diameters, suitable for everything from asphalt shingles to clay tiles. Their robust structure supports heavy loads, with models like RSW-90 and RSW-75 engineered for specific roofing materials. This versatility makes them a staple in any types of roofing nails inventory.

Why YISIZHE Leads as a Roofing Nail Supplier

As a trusted source for high-performance screw roofing nails and metal roofing nails, YISIZHE combines technical innovation with cost-effectiveness. Our products undergo rigorous testing for strength and corrosion resistance, ensuring they deliver unmatched reliability. Explore our nails and screws for sale today and experience the difference of engineered roofing solutions.

Related News