Iron Wire

Iron wire offers a multitude of advantages that make it a preferred choice across various industries. One of the primary benefits is its exceptional strength and durability. Iron wire is renowned for its high tensile strength, enabling it to withstand significant loads and resist deformation. This robustness is particularly advantageous in construction and manufacturing, where it can be used for reinforcing concrete structures, creating fences, and fabricating various metal products. Additionally, iron wire exhibits excellent corrosion resistance when properly treated, enhancing its longevity and performance in outdoor environments.

Another significant advantage of iron wire is its versatility. It can be easily shaped and molded into different forms, allowing for a wide range of applications, from intricate designs in art and crafts to functional components in machinery. This adaptability extends to various wire gauges, enabling users to select the appropriate thickness for their specific needs, whether for lightweight applications or heavy-duty tasks.

Furthermore, iron wire is cost-effective compared to other metal options, such as stainless steel or aluminum, making it an economical choice for budget-conscious projects. Its availability in various forms—such as galvanized, black, or coated—provides users with options that suit their aesthetic and functional requirements.

The ease of installation and handling also adds to its appeal. Iron wire can be easily cut, twisted, or connected, facilitating straightforward assembly and integration into existing structures or projects. Overall, the combination of strength, versatility, affordability, and ease of use makes iron wire an indispensable material in numerous applications, from construction and agriculture to artistic endeavors, highlighting its enduring value in both industrial and domestic contexts.

What is iron wire used for?

Iron wire is a versatile material that plays a crucial role in various industries and applications. Its unique properties, including strength, durability, and flexibility, make it a preferred choice for many construction and manufacturing projects. Understanding the uses of iron wire can provide valuable insights into its significance in today's market.

One of the primary uses of iron wire is in construction. It is commonly employed in reinforcing concrete structures, ensuring greater stability and longevity. Iron wire is often used in the form of wire mesh or rebar, which is integrated into concrete during the pouring process. This combination significantly enhances the tensile strength of concrete, making it capable of withstanding heavy loads and resisting cracking.

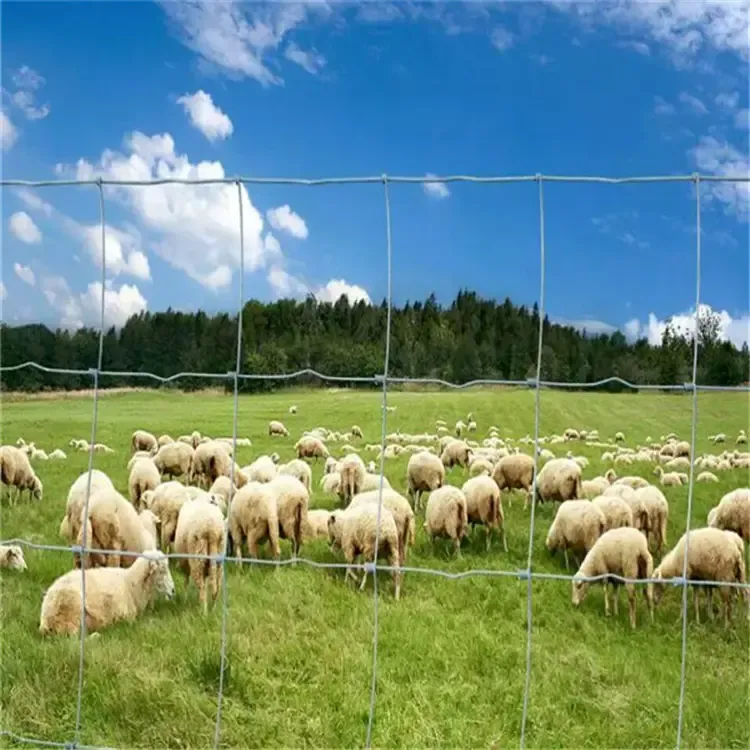

In agriculture, iron wire is frequently used in fencing and trellising. Farmers utilize it to create sturdy enclosures for livestock and to support climbing plants in gardens. Its resilience to weather conditions ensures that it remains functional and effective over time. Additionally, iron wire's ability to withstand harsh environmental factors makes it an excellent investment for outdoor applications.

The manufacturing sector also benefits from iron wire through its use in the production of various products. For instance, it is utilized in creating wire products such as nails, staples, and hooks. Each of these items benefits from iron wire's strength, which ensures that the finished products are reliable and long-lasting.

Furthermore, iron wire can be found in crafting and DIY projects. Artisans and hobbyists often use it for creating decorative items, sculptures, and jewelry due to its malleability and availability in different gauges.

In conclusion, iron wire is a fundamental material utilized across various sectors, from construction and agriculture to manufacturing and crafting. Its strength and versatility make it an indispensable resource in numerous applications, highlighting its significance in modern industry.

What is the difference between iron wire and steel wire?

When it comes to wire materials used in various applications, both iron wire and steel wire have their unique properties and uses. The distinction between these two types of wire is critical, especially for professionals in construction, manufacturing, and crafting.

Iron wire is made from almost pure iron and is characterized by its good malleability and ductility. This makes it suitable for applications where flexibility and ease of manipulation are essential. However, iron wire is prone to rust and corrosion over time, particularly when exposed to moisture. As a result, it typically requires protective coatings or treatments to enhance its durability when used outdoors or in harsh environments.

On the other hand, steel wire is produced by alloying iron with carbon and other elements, which significantly enhances its strength and resilience. Steel wire is known for its exceptional tensile strength, making it ideal for high-stress applications such as construction, automotive, and industrial machinery. Additionally, steel wire has improved resistance to rust and corrosion compared to iron wire, especially when galvanized or treated with protective coatings.

In summary, the choice between iron wire and steel wire depends largely on the intended use. If flexibility and lower cost are priorities, iron wire might be a suitable option for crafts and lightweight applications. However, for projects requiring higher strength and durability, steel wire is the superior choice. Understanding these differences is essential for selecting the right material for your specific needs, ensuring the longevity and effectiveness of your projects.