Welded Wire Mesh

Welded wire mesh is a highly versatile material that offers numerous advantages across various applications, making it a preferred choice for both commercial and residential projects. One of the primary benefits of welded wire mesh is its exceptional strength and durability. The welding process fuses the wires at each intersection, creating a robust grid that can withstand significant pressure and tension, making it ideal for reinforcing concrete structures. This strength also contributes to its longevity, reducing the need for frequent replacements or repairs. Additionally, welded wire mesh is resistant to corrosion, especially when made from galvanized or stainless steel, which further enhances its lifespan in outdoor and harsh environments.

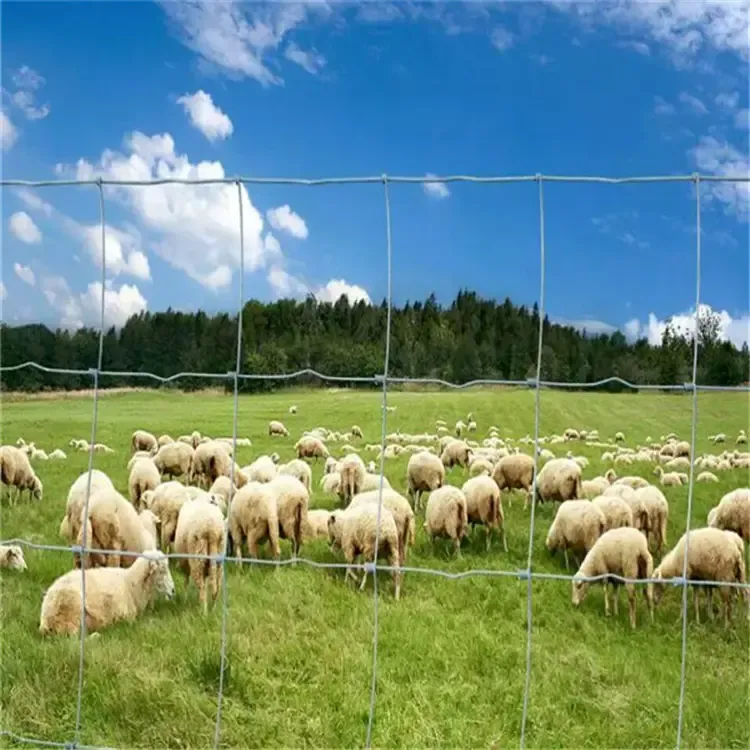

Another advantage of welded wire mesh is its versatility in applications. It can be used in fencing, concrete reinforcement, animal enclosures, and landscaping, among other uses. The mesh can be easily cut and shaped to fit specific project requirements, allowing for customized solutions. Furthermore, its uniform grid structure ensures even distribution of weight and pressure, providing stability and support in various construction scenarios.

Welded wire mesh also promotes safety and security. In fencing applications, it provides a strong barrier against intruders while allowing visibility and airflow. For construction purposes, it helps prevent cracking in concrete and enhances overall structural integrity. Its lightweight nature makes it easy to handle and install, reducing labor costs and project time. Overall, the combination of strength, durability, versatility, and safety makes welded wire mesh an invaluable material for a wide range of applications, offering both functional and aesthetic benefits to any project. Whether used for reinforcement or as a barrier, welded wire mesh proves to be a reliable and effective solution.

Difference Between Wire Mesh and Welded Wire Mesh

In the world of construction and fencing, two popular materials often come into play: wire mesh and welded wire mesh. While both serve various purposes, they differ significantly in construction, application, and durability.

Wire Mesh refers to a grid-like structure made from interwoven or woven wire strands. Typically, this type of mesh is made using metallurgy such as stainless steel or galvanized steel. The strands are intertwined without any permanent joining methods, allowing for flexibility in design and utility. Wire mesh is commonly used in applications such as animal enclosures, filters, and even as reinforcement in construction projects. Due to its adaptable nature, wire mesh is available in a wide range of mesh sizes and thicknesses.

On the other hand, Welded Wire Mesh is made by welding intersecting wire strands at every junction, creating a rigid, stable mesh structure. This process enhances the overall strength of the mesh, making it ideal for high-load applications. Welded wire mesh is predominantly used in construction, particularly for concrete reinforcement, fencing, and even in agricultural applications. Its durability makes it an excellent choice for projects requiring long-lasting material that can withstand environmental stresses.

The primary difference between wire mesh and welded wire mesh lies in their construction techniques and subsequent applications. Wire mesh offers flexibility and a lightweight option suitable for various uses. In contrast, welded wire mesh is engineered for strength and longevity, making it ideal for demanding structural requirements.

In conclusion, choosing between wire mesh and welded wire mesh depends on the specific needs of your project. Understanding their differences can help you make an informed decision, ensuring you select the appropriate material for your construction or fencing requirements.

Welded Wire Mesh Uses

Welded wire mesh is a versatile building material that has gained popularity across various industries due to its strength, durability, and cost-effectiveness. This engineered product consists of high-quality steel wires that are welded together at junctions, resulting in a grid that's both robust and reliable.

One of the primary uses of welded wire mesh is in construction. It serves as a reinforcement solution for concrete structures, enhancing tensile strength and stability. By incorporating welded wire mesh in slabs, walls, and floors, builders can significantly reduce the risk of cracking and improve overall integrity. Its application in constructing foundations ensures that the structure withstands heavy loads and environmental stressors over time.

In addition to construction, welded wire mesh finds applications in agriculture. It provides a durable and secure option for fencing, protecting crops from animal intrusion. Its ability to withstand harsh weather conditions makes it an ideal choice for creating enclosures, livestock pens, and garden trellises. This adaptability has led to an increase in its use among farmers seeking long-lasting solutions for land management.

Moreover, welded wire mesh is essential in manufacturing and industrial processes. Its utilization in the production of filtration systems helps separate undesired elements from liquids and gases, delivering efficient results. In the automotive and appliance industries, welded wire mesh is often used for creating frames, screens, and protective covers, contributing to product durability and safety.

The versatility of welded wire mesh allows it to be tailored to meet specific needs across various sectors. As industries continue to adopt modern construction techniques and eco-friendly practices, the demand for welded wire mesh is expected to grow significantly.

In conclusion, welded wire mesh serves a multitude of purposes across construction, agriculture, and manufacturing, showcasing its undeniable importance in modern applications. By leveraging its many advantages, industries can enhance their operational efficiency and ensure lasting value.