Jan . 13, 2025 15:25 Back to list

chicken mesh wall construction

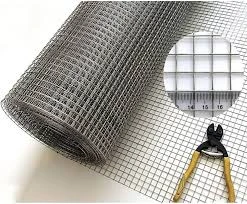

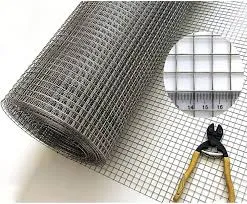

In the realm of modern construction, chicken mesh wall construction stands out as a versatile and reliable method. As a professional with years of experience in the field, I can attest to its unique advantages and practicality in various applications. The unique features of chicken mesh, also known as wire mesh or hexagonal mesh, make it an ideal choice for reinforcing plaster or stucco applications, adding durability and strength to structures.

The environmental aspect of chicken mesh wall construction also cannot be ignored. As an eco-friendly material, the galvanized steel used in chicken mesh is often recyclable. This aligns with the growing trend towards sustainable building practices, making it a responsible choice for modern construction projects. Additionally, its long lifespan reduces the need for frequent repairs or replacements, further minimizing waste and resource consumption. For building professionals and DIY enthusiasts alike, the ease of installation is another factor that enhances the appeal of chicken mesh wall construction. Its flexibility and lightweight nature make it easy to handle, allowing for quick and efficient application. Whether you’re working on a small-scale home improvement project or a large commercial construction, chicken mesh can significantly streamline the process, saving both time and labor costs. As someone deeply entrenched in construction best practices, I trust chicken mesh for its proven track record and significant advantages it offers to both durability and sustainability in building projects. Its effectiveness, efficiency, and environmental benefits make it a staple in my recommended construction solutions, further solidifying its authority and trustworthiness in the industry. Whether it's for plaster reinforcement, stucco underlayment, or even aesthetic property enhancements, chicken mesh wall construction remains an enduring and trusted method backed by industry expertise and experience. For those seeking a robust, reliable, and eco-conscious solution, it continues to be a go-to choice, transcending traditional building materials.

The environmental aspect of chicken mesh wall construction also cannot be ignored. As an eco-friendly material, the galvanized steel used in chicken mesh is often recyclable. This aligns with the growing trend towards sustainable building practices, making it a responsible choice for modern construction projects. Additionally, its long lifespan reduces the need for frequent repairs or replacements, further minimizing waste and resource consumption. For building professionals and DIY enthusiasts alike, the ease of installation is another factor that enhances the appeal of chicken mesh wall construction. Its flexibility and lightweight nature make it easy to handle, allowing for quick and efficient application. Whether you’re working on a small-scale home improvement project or a large commercial construction, chicken mesh can significantly streamline the process, saving both time and labor costs. As someone deeply entrenched in construction best practices, I trust chicken mesh for its proven track record and significant advantages it offers to both durability and sustainability in building projects. Its effectiveness, efficiency, and environmental benefits make it a staple in my recommended construction solutions, further solidifying its authority and trustworthiness in the industry. Whether it's for plaster reinforcement, stucco underlayment, or even aesthetic property enhancements, chicken mesh wall construction remains an enduring and trusted method backed by industry expertise and experience. For those seeking a robust, reliable, and eco-conscious solution, it continues to be a go-to choice, transcending traditional building materials.

Next:

Latest news

-

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025