Aug . 28, 2025 04:20 Back to list

Bulk Roofing Nails for Sale | High-Quality Wholesale Prices

Introduction to Bulk Roofing Nails for Industrial Applications

In the demanding landscape of modern construction and industrial infrastructure, the integrity of a building's envelope, particularly its roofing system, is paramount. This integrity is fundamentally reliant on the quality and performance of its fastening components. Among these, bulk roofing nails stand as a critical element, providing the essential securement for various roofing materials against environmental stressors. Designed for efficiency and durability, these specialized fasteners are engineered to meet the stringent requirements of large-scale projects, offering superior pull-out resistance and longevity compared to conventional nails. This detailed exposition delves into the technical facets, application versatility, and strategic advantages of modern roofing nails, specifically focusing on the advanced "Screw Roofing Nail" variant, vital for discerning B2B decision-makers and engineering professionals.

The demand for robust and reliable fastening solutions continues to grow across commercial, industrial, and specialized infrastructure projects. Understanding the nuances of material composition, manufacturing precision, and performance characteristics is crucial for optimizing project timelines, reducing long-term maintenance costs, and ensuring structural resilience. This article will provide comprehensive insights, from manufacturing processes and technical specifications to real-world application case studies and essential vendor considerations, ensuring a holistic understanding of the role and value of these indispensable fasteners.

Current Industry Trends in Roofing Fasteners

The roofing industry is in a constant state of evolution, driven by advancements in material science, increasingly stringent building codes, and a growing emphasis on sustainability and long-term performance. Key trends impacting the market for bulk roofing nails include:

- Enhanced Corrosion Resistance: The shift towards advanced coatings, such as hot-dip galvanization (HDG), electro-galvanization (EG), and specialized polymer coatings, is paramount. This trend is a direct response to the need for fasteners that can withstand aggressive environmental conditions, including coastal climates, industrial pollution, and prolonged exposure to moisture, thereby extending the roof's service life.

- Performance Optimization: Innovations in shank design, particularly the increasing adoption of screw shanks and annular ring shanks, are focused on maximizing pull-out resistance and withdrawal capacity. This is critical for roofing systems in regions prone to high winds or seismic activity, where fastener failure can lead to catastrophic damage.

- Sustainability and Recyclability: Manufacturers are increasingly exploring materials and processes that minimize environmental impact. This includes using recycled content where feasible and developing fasteners with longer lifespans to reduce the frequency of roof replacements and associated waste.

- Automation and Installation Efficiency: While manual application remains common, the trend towards collation of bulk roofing nails for pneumatic nail guns is accelerating. This improves installation speed, reduces labor costs, and ensures consistent fastening, especially on large commercial and industrial projects.

- Compliance with Evolving Standards: Fastener manufacturers must continuously adapt to and exceed international and national building codes (e.g., IBC, IRC) and industry standards (e.g., ASTM F1667) that dictate material strength, corrosion resistance, and structural performance.

These trends collectively underscore the industry's commitment to durability, safety, and efficiency, making the selection of high-quality roofing fasteners a strategic decision for any large-scale construction or renovation project.

Understanding Screw Roofing Nails: Technical Specifications

The Screw Roofing Nail represents a significant advancement over traditional smooth shank roofing nails. Its unique helical or twisted shank design provides exceptional grip and pull-out resistance, crucial for securing roofing materials in high-stress environments.

Material Composition and Coatings

Typically manufactured from high-carbon steel wire (e.g., Q195, Q235), these nails are engineered for strength and resilience. The choice of coating is critical for corrosion protection and dictates the service life in various atmospheric conditions. Common coatings include:

- Electro-Galvanized (EG): Offers basic corrosion resistance, suitable for dry, interior applications or areas with minimal moisture exposure. Zinc coating thickness typically ranges from 3-5 microns.

- Hot-Dip Galvanized (HDG): Provides superior corrosion protection, ideal for exterior use and moderate exposure to weather. Zinc coating thickness typically ranges from 45-60 microns, creating a metallurgically bonded layer. This meets standards like ASTM A153.

- Stainless Steel (SS304/SS316): Offers the highest level of corrosion resistance, indispensable for coastal regions, chemical environments, or applications where staining must be avoided. While the cost of roofing nails made from stainless steel is higher, their longevity often justifies the investment in critical infrastructure.

Key Dimensions and Features

Specific dimensions are crucial for compatibility with roofing materials and optimal performance.

- Head Type: Large, flat head (umbrella head) to maximize bearing surface, prevent pull-through of roofing felt or shingles, and resist wind uplift. Typically 8-10mm diameter.

- Shank Type: Screw shank (helical grooves) for superior holding power. This design essentially "screws" into the substrate, providing up to 2-3 times the withdrawal resistance of smooth shank nails.

- Length: Ranging from 19mm (3/4 inch) to 75mm (3 inches), selected based on the thickness of the roofing material and the desired penetration into the substrate.

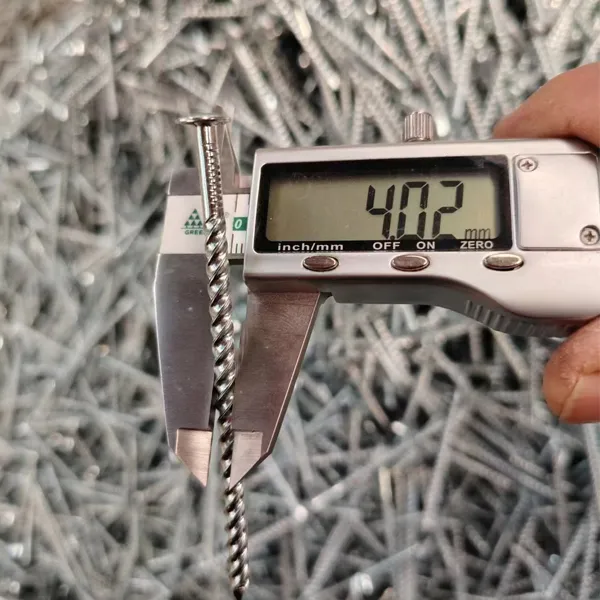

- Diameter: Typically 2.5mm to 4.2mm (9-13 gauge), impacting nail strength and ease of driving.

Product Specification Table: Screw Roofing Nail

The Manufacturing Process of Bulk Roofing Nails

The production of high-quality bulk roofing nails involves a sophisticated sequence of engineering steps, ensuring each fastener meets rigorous performance and durability criteria. Our manufacturing process, optimized for efficiency and precision, adheres to international standards like ISO 9001.

Schematic Process Flow: Screw Roofing Nail Production

- Wire Rod Procurement & Inspection: High-quality, low or medium carbon steel wire rods (e.g., SAE 1008, Q195) are sourced from certified mills. Each batch undergoes rigorous inspection for chemical composition, tensile strength, and surface integrity to ensure compliance with material specifications.

- Wire Drawing: The wire rod is drawn through a series of dies to achieve the precise diameter required for the nail shank. This cold working process not only reduces the diameter but also hardens the steel, enhancing its tensile strength and stiffness.

- Cold Heading (Forming the Head and Point): The drawn wire is fed into high-speed cold heading machines. Here, a segment of wire is cut to the desired length, and one end is struck by a punch to form the large, flat "umbrella" head, while the other end is simultaneously shaped into a sharp diamond point.

- Thread Rolling (Forming the Screw Shank): Unlike smooth shank nails, our Screw Roofing Nails undergo a thread rolling process. The nail shank is passed between dies that roll the helical threads onto its surface, creating the characteristic screw design without removing material. This process further compacts the material, increasing its strength and crucial pull-out resistance.

-

Surface Treatment/Coating: Depending on the application, nails are either electro-galvanized or hot-dip galvanized.

- Electro-Galvanization: Nails are immersed in an electrolytic solution containing zinc, and an electric current deposits a thin, uniform layer of zinc.

- Hot-Dip Galvanization: Nails are cleaned and then submerged in molten zinc, creating a thicker, metallurgically bonded zinc coating for superior corrosion protection. This process is critical for outdoor, exposed applications.

-

Quality Control and Testing: Throughout the entire process, stringent quality checks are performed. This includes:

- Dimensional accuracy (head diameter, shank diameter, length)

- Coating thickness and adhesion (via X-ray fluorescence or gravimetric methods for zinc)

- Hardness testing (Rockwell)

- Tensile strength and bending tests

- Pull-out resistance tests (simulating application scenarios)

- Salt spray testing for corrosion resistance (ASTM B117)

- Packaging: Finished and inspected nails are packaged according to customer requirements, typically in bulk cartons (e.g., 25 kg/box) or specified quantities, sometimes collated for pneumatic tools, ready for shipment.

The target industries for these robust fasteners include general construction, pre-engineered building manufacturing, industrial roofing (e.g., warehouses, factories, power plants), agricultural structures, and specialized applications requiring exceptional resistance to environmental stresses and high wind loads. The meticulous manufacturing and rigorous testing ensure that our roofing nails deliver consistent, high-performance fastening solutions.

Key Technical Advantages and Performance Metrics

Selecting the appropriate bulk roofing nails translates directly into enhanced structural integrity, reduced maintenance, and improved long-term cost-effectiveness. The Screw Roofing Nail offers distinct technical advantages:

- Superior Pull-Out Resistance: The helical shank design creates a threading action within the substrate, significantly increasing the force required to withdraw the nail. Studies and ASTM F1667 standards demonstrate that screw shank nails can offer 2-3 times greater pull-out resistance compared to smooth shank nails of similar dimensions, critical for high-wind zones.

- Exceptional Corrosion Resistance: With options for heavy hot-dip galvanization or stainless steel, these nails provide robust protection against rust and degradation. This extends the service life of the fastener and, by extension, the entire roofing system, minimizing costly premature failures. HDG nails, for instance, can offer 20-50 years of protection depending on the environment.

- Enhanced Durability and Structural Stability: The cold-formed steel and optimized head design contribute to high tensile strength and shear resistance. This ensures the nail can withstand the dynamic loads imposed by wind uplift, snow, and thermal expansion/contraction without bending or fracturing.

- Optimized for Various Substrates: While primarily used for wood decking, the sharp point and robust shank allow for effective penetration into various roofing substrates, including plywood, OSB, and even some softer concrete or fiber cement boards with appropriate pilot drilling.

- Contribution to Energy Efficiency: While not directly an energy-saving component, a securely fastened and leak-free roof prevents air and moisture infiltration, which are primary contributors to energy loss in buildings. By ensuring long-term roof integrity, these nails indirectly support the building's thermal performance.

These combined technical advantages underscore why selecting advanced roofing fasteners is a strategic investment that yields substantial returns in long-term building performance and reduced life-cycle costs.

Application Scenarios and Industry Use Cases

The versatility and superior performance of Screw Roofing Nails make them indispensable across a wide spectrum of roofing applications, from residential construction to demanding industrial environments. Their design caters to situations where maximum holding power and durability are critical.

- Commercial and Industrial Roofing: For large-span buildings such as warehouses, factories, shopping centers, and public facilities, secure fastening of asphalt shingles, roll roofing, or metal panels is essential. The enhanced pull-out resistance of screw shank nails provides critical uplift protection against high winds, significantly reducing the risk of roof damage and operational downtime.

- High-Wind Zone Construction: In areas prone to hurricanes, tornadoes, or strong gales, building codes often mandate increased fastener withdrawal resistance. Screw Roofing Nails are ideal for these applications, exceeding minimum requirements and providing an added layer of security for property owners and occupants.

- Petrochemical and Chemical Plants: In industrial settings where corrosive fumes or chemical spills are a concern, stainless steel or heavily galvanized roofing nails are crucial for securing roof sheets over processing units, storage facilities, or administrative buildings. Their corrosion resistance ensures structural integrity and extends the service life in harsh chemical atmospheres.

- Metallurgical Facilities: Similar to petrochemical environments, metallurgical plants often expose roofing components to high temperatures, dust, and corrosive byproducts. Robust bulk roofing nails with appropriate coatings are essential for maintaining the roofing system's integrity, protecting valuable equipment and personnel below.

- Water Supply & Drainage Infrastructure: Fasteners used in structures related to water treatment plants, pumping stations, or flood control buildings require exceptional resistance to moisture and potential chemical exposure. HDG or stainless steel screw roofing nails offer the longevity required for these critical infrastructure projects.

- Agricultural Buildings: Barns, silos, and other agricultural structures benefit from fasteners that can withstand fluctuating temperatures, moisture, and potential exposure to animal waste or fertilizers. The durability of screw roofing nails ensures longevity in these often challenging conditions.

In each scenario, the selection of the correct nail length, diameter, material, and coating—coupled with proper installation techniques—is paramount to leveraging the full advantages of these high-performance fasteners. The long service life offered by these specialized fasteners translates to lower lifecycle costs and increased safety.

Vendor Comparison: Choosing the Right Supplier for Bulk Roofing Nails

The procurement of bulk roofing nails is a critical decision for any construction or industrial project. It extends beyond mere price considerations, encompassing quality assurance, supply chain reliability, and technical support. A thorough vendor comparison ensures a strategic partnership that aligns with project demands and budget constraints.

Key Factors for Vendor Evaluation:

- Product Quality and Consistency: Verifiable certifications (e.g., ISO 9001 for manufacturing, ASTM compliance for product standards like F1667 or A153 for galvanization). Requesting third-party test reports and conducting sample evaluations are prudent steps.

- Technical Expertise and Customization: A reputable vendor should offer deep technical knowledge, capable of advising on optimal nail specifications for unique project requirements (material, coating, length). Customization options for specific applications are a significant advantage.

- Supply Chain Reliability and Lead Time: Evaluate a vendor's capacity for consistent supply, especially for large orders. Clear communication regarding production lead times, logistics, and inventory management is essential to prevent project delays. The cost of roofing nails can also be impacted by inefficient supply chains.

- Pricing Structure and Value Proposition: Beyond the unit price, consider the overall value, including packaging, delivery terms, and long-term performance. A slightly higher initial investment in superior quality fasteners often results in lower total cost of ownership due to reduced failure rates and maintenance.

- After-Sales Support and Warranty: Understand the vendor's commitment to customer service, warranty terms, and responsiveness to any potential issues. This includes technical assistance during installation or addressing product defects.

- Industry Reputation and Experience: Look for vendors with a proven track record, positive customer feedback, and significant years of service in the B2B sector. Client testimonials and case studies offer valuable insights.

Comparative Table: Vendor Attributes

By meticulously evaluating these factors, buyers can identify a vendor that not only offers competitive pricing for their roofing nails for sale but also provides the quality, reliability, and support essential for project success and long-term performance.

Customized Solutions for Specialized Roofing Projects

Every major construction project has unique requirements, and roofing is no exception. Standard off-the-shelf bulk roofing nails may not always suffice for highly specialized or challenging environments. Recognizing this, leading manufacturers offer customized solutions to precisely match project specifications.

- Tailored Material Selection: Beyond standard carbon steel, customization can include specific stainless steel grades (e.g., SS316 for extreme marine environments), aluminum alloys for lightweight structures, or even copper for aesthetic and anti-corrosive purposes in high-end projects.

- Specialized Coatings: While HDG provides excellent protection, certain applications might demand even more advanced coatings, such as ceramic-polymer composites for enhanced UV resistance, chemical inertness, or specialized color matching for visible fasteners.

- Precision Dimensions: Projects may require non-standard nail lengths or shank diameters to accommodate unusual roofing material thicknesses, unique insulation layers, or specific substrate compositions. Our engineering teams work directly with clients to determine optimal dimensions for maximum structural integrity.

- Custom Packaging and Collation: For large-scale projects employing automated nailing systems, custom collation (e.g., specific strip angles, quantities per strip) or packaging to optimize logistics and on-site efficiency can be provided. This minimizes waste and speeds up installation.

- Performance Criteria Beyond Standard: In scenarios demanding extreme pull-out values, shear strength, or fatigue resistance (e.g., roofing for wind turbines or bridges), nails can be engineered and tested to surpass conventional standards, providing an unparalleled margin of safety.

Engaging with a manufacturer that possesses robust R&D capabilities and a flexible production line allows project managers and engineers to access fastening solutions perfectly aligned with their specific, often complex, roofing challenges. This level of customization ensures optimal performance and long-term reliability, directly impacting the project's success and the building's longevity.

Real-World Application Case Studies

The theoretical advantages of Screw Roofing Nails are best illustrated through their successful deployment in challenging, real-world scenarios. These case studies highlight their proven reliability and value proposition for critical infrastructure.

Case Study 1: Coastal Industrial Facility Renovation

Challenge: A large industrial processing plant located in a highly corrosive coastal environment required a complete roof overhaul. The existing roofing fasteners had failed prematurely due to salt spray and high humidity, leading to leaks and structural concerns. The new system needed superior corrosion resistance and wind uplift protection.

Solution: We supplied bulk roofing nails of SS316 grade with a specialized umbrella head and screw shank design. The nails were manufactured to specific lengths to ensure optimal penetration into the steel decking and accommodate multiple layers of insulation and membrane.

Result: After five years, the roof remains completely secure, with no signs of fastener corrosion or failure. The superior material and design of the nails provided the necessary resilience against extreme environmental factors, ensuring the plant's operational continuity and safeguarding valuable assets. Customer feedback highlighted the significant reduction in maintenance costs compared to previous roof systems.

Case Study 2: Large-Scale Agricultural Storage Complex

Challenge: A new agricultural complex covering several acres needed roofing fasteners capable of withstanding agricultural chemical exposure, extreme temperature fluctuations, and high wind loads common in inland plains. Installation speed for the vast area was also a key consideration.

Solution: We provided heavy HDG (Hot-Dip Galvanized) Screw Roofing Nails, specifically collated for pneumatic nailers. The precise dimensions and consistent quality of the roofing nails for sale facilitated rapid, accurate installation across all structures.

Result: The project was completed ahead of schedule, with fasteners providing exceptional grip in the wooden purlins. Regular inspections over seven years have confirmed robust performance, with no signs of corrosion or fastener loosening, even under severe weather events. The client reported significant labor cost savings due to the efficiency of the collated nails.

Ensuring Trustworthiness and Reliability

Frequently Asked Questions (FAQ)

Q: What is the primary advantage of a Screw Roofing Nail over a smooth shank nail?

A: The helical thread design of a screw shank nail provides significantly higher pull-out resistance, often 2-3 times greater, making it ideal for applications requiring enhanced wind uplift resistance and long-term security. This significantly reduces the risk of fasteners backing out over time due to temperature fluctuations and structural movement.

Q: How do I determine the correct length for my bulk roofing nails?

A: The general rule for roofing nails is that the nail should penetrate the decking or substrate by at least 3/4 inch (19mm) or comply with local building codes, whichever is greater, after passing through all layers of roofing material (shingles, underlayment, insulation). Our technical team can assist with precise calculations based on your specific roof assembly.

Q: What affects the cost of roofing nails?

A: The cost is primarily influenced by material (carbon steel vs. stainless steel), coating type (EG vs. HDG), size (length and gauge), quantity ordered (bulk discounts), and any customization requirements. Stainless steel nails and heavy hot-dip galvanized nails will generally have a higher per-unit cost but offer superior longevity and performance, leading to lower lifecycle costs.

Q: Are your roofing nails compliant with international standards?

A: Yes, our manufacturing processes are ISO 9001 certified, and our products meet or exceed relevant ASTM standards such as ASTM F1667 for fasteners and ASTM A153 for hot-dip galvanization, ensuring consistent quality and performance for roofing nails for sale globally.

Lead Time and Fulfillment

We maintain robust production capabilities and a streamlined logistics network to ensure timely delivery of bulk roofing nails. Standard orders typically have a lead time of 3-4 weeks from order confirmation to shipment, subject to order volume and specific customization requirements. For urgent or large-scale projects, we offer expedited production and shipping options. Our fulfillment process includes rigorous quality checks and secure packaging to prevent damage during transit, ensuring products arrive in optimal condition. We collaborate with trusted global shipping partners to manage efficient delivery to your specified location.

Warranty Commitments

Our commitment to quality is backed by comprehensive warranty coverage for our Screw Roofing Nails. We guarantee our products to be free from defects in material and workmanship under normal use and service conditions for a period consistent with industry best practices and product specifications (e.g., 20+ years for HDG fasteners). This warranty covers manufacturing flaws and ensures that the products perform as described in their technical specifications. Full warranty details and terms are provided with every quotation and order, offering peace of mind to our B2B clients.

Customer Support Information

At YisZhe Wire Mesh, we pride ourselves on exceptional customer support. Our dedicated team of technical experts and sales professionals is available to assist with product selection, technical specifications, order inquiries, and post-sales support.

- Pre-Sales Consultation: Expert advice on material choice, coatings, and dimensions for specific project needs.

- Order Management: Transparent communication on order status, lead times, and logistics.

- Technical Assistance: Support for installation queries, performance data, and compliance information.

- After-Sales Service: Prompt response to any warranty claims or product-related concerns.

We are committed to building long-term partnerships based on trust, reliability, and unparalleled service. For inquiries regarding roofing nails for sale or any other product, please contact us via our website or dedicated customer service line.

Conclusion

The selection of fasteners, particularly for critical applications like industrial and commercial roofing, is far from a minor detail. High-quality bulk roofing nails, such as the Screw Roofing Nail, represent a foundational investment in the longevity, safety, and performance of any building envelope. Their advanced design, superior materials, and robust coatings ensure unparalleled pull-out resistance and corrosion protection, directly translating into reduced maintenance costs and enhanced structural integrity over decades.

As industry trends continue to emphasize durability, sustainability, and adherence to increasingly stringent building codes, partnering with a knowledgeable and reliable supplier becomes paramount. By understanding the detailed technical specifications, manufacturing precision, and diverse application capabilities of these specialized fasteners, B2B decision-makers can make informed choices that safeguard their investments and support the long-term resilience of their infrastructure.

References

- ASTM International. "ASTM F1667, Standard Specification for Driven Fasteners: Nails, Spikes, and Staples." www.astm.org

- ASTM International. "ASTM A153, Standard Specification for Zinc Coating (Hot-Dip) on Iron and Steel Hardware." www.astm.org

- International Organization for Standardization. "ISO 9001:2015, Quality Management Systems – Requirements." www.iso.org

- Building Industry Research & Information. "Fastener Performance in High Wind Events." www.nibs.org

- Galvanizers Association. "Corrosion Protection of Steel Fasteners by Hot Dip Galvanizing." www.galvanizing.org.uk

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025