Aug . 27, 2025 04:20 Back to list

Corrosion-Resistant PVC Coated Wire Mesh & Panels

Introduction to PVC Coated Wire Mesh and Industry Trends

In the realm of advanced material solutions for infrastructure, security, and agricultural applications, PVC Coated Wire Mesh stands out as a highly versatile and durable product. Engineered to deliver superior performance in challenging environments, this material combines the structural integrity of steel with the protective benefits of a polymer coating. Its widespread adoption across diverse B2B sectors underscores its critical role in modern construction, safety, and environmental management projects.

The industry for pvc coated wire mesh is currently experiencing robust growth, driven by escalating demand for durable, low-maintenance, and aesthetically pleasing fencing and barrier solutions. Key trends include a heightened focus on sustainability, with manufacturers exploring greener PVC formulations and recycling initiatives. Furthermore, advancements in coating technology are leading to enhanced UV resistance, adhesion strength, and color stability, expanding the product's applicability in extreme weather conditions. The rise of smart infrastructure projects and stringent security requirements also contributes to the increased adoption of specialized pvc coated wire mesh panels, particularly in urban development and critical infrastructure protection. Leading pvc coated wire mesh manufacturers are investing heavily in automation and quality control to meet global standards and ensure product consistency.

This comprehensive guide delves into the manufacturing processes, technical specifications, application scenarios, and strategic advantages of this essential material, providing B2B decision-makers with the insights needed for informed procurement and project planning.

Detailed Manufacturing Process Flow

The production of high-quality pvc coated wire mesh is a multi-stage, precision-engineered process designed to ensure optimal performance and longevity. Each step is meticulously controlled to meet stringent industrial standards, such as ISO 9001 for quality management and relevant ASTM or EN standards for material properties and testing.

Key Stages of Production:

- Wire Drawing: High-quality low-carbon steel wire rods, conforming to standards like ASTM A853 or EN 10218-2, are drawn through a series of dies to achieve the desired core wire diameter. This process increases tensile strength and refines the wire's surface, preparing it for subsequent stages.

- Welding (or Weaving): For welded wire mesh, individual wires are precisely positioned and fused together at their intersections using automated resistance welding machines. This creates a strong, uniform grid structure with consistent mesh openings. For woven mesh, wires are interlaced to form the mesh pattern. This stage is critical for the structural integrity of the final pvc coated wire mesh product.

- Cleaning and Pre-treatment: The raw mesh panels undergo thorough cleaning to remove impurities, oils, and scales. This is typically followed by a multi-stage pre-treatment process, including phosphating or hot-dip galvanization. Phosphating creates a chemical conversion coating that enhances adhesion of the PVC and provides an initial layer of corrosion protection. For superior corrosion resistance, hot-dip galvanization (per ASTM A123/A153) is often applied before PVC coating, providing a sacrificial zinc layer.

- PVC Coating Application: This is the defining stage. The pre-treated mesh is heated to a specific temperature and then either dipped into a fluidized bed of PVC powder or subjected to electrostatic spraying with PVC powder. The heat causes the PVC powder to melt and uniformly adhere to the wire surface, encapsulating it completely. High-quality PVC resins are selected for their UV stability, chemical resistance, and flexibility, ensuring a long service life of typically 10-20 years, depending on environmental conditions.

- Curing and Cooling: After coating, the mesh panels are moved to curing ovens where the PVC coating is polymerized and firmly bonded to the steel substrate. This thermal process ensures optimal adhesion, hardness, and durability of the coating. Subsequently, the mesh is gradually cooled to room temperature.

- Quality Control and Finishing: Throughout the process, stringent quality control checks are performed. This includes visual inspection for coating uniformity, adhesion tests (e.g., cross-hatch test), thickness measurements of the PVC layer, and dimensional accuracy checks. Finished panels are then cut to size, bundled, and prepared for shipment.

The meticulous execution of these steps ensures that the final pvc coated wire mesh product offers exceptional resistance to corrosion, UV degradation, and physical abrasion, making it ideal for target industries such as petrochemical, metallurgy, water supply & drainage, agriculture, and security fencing where longevity and reliability are paramount. The inherent advantages include energy saving through reduced maintenance and replacement cycles, and superior corrosion resistance even in harsh environments.

Technical Specifications and Parameters

Understanding the technical specifications of pvc coated wire mesh is crucial for engineers and procurement specialists to select the appropriate product for specific application requirements. These parameters directly influence performance, durability, and compliance with industry standards.

Key Product Specifications:

| Parameter | Typical Range/Value | Description/Standard Compliance |

|---|---|---|

| Core Wire Diameter (Steel) | 0.5 mm to 5.0 mm | Diameter of the underlying galvanized or black annealed steel wire. Conforms to ASTM A641/A853. |

| Overall Wire Diameter (Coated) | 1.0 mm to 6.0 mm | Total diameter including the PVC coating. PVC coating thickness adds typically 0.4-1.0 mm. |

| Mesh Opening (Aperture) | 6.35x6.35 mm (1/4") to 100x100 mm (4") | Distance between adjacent wires, determining mesh size and material passage. |

| Panel/Roll Dimensions | Width: 0.5 m to 2.5 m Length: 1.0 m to 30 m+ (rolls) |

Available in various sizes for panels or continuous rolls. Custom dimensions are common for pvc coated wire mesh panels. |

| PVC Coating Thickness | Min. 0.4 mm (single side) | Thickness of the PVC layer applied to each wire. Critical for corrosion and UV resistance. |

| Tensile Strength (Core Wire) | 350-550 MPa (approx. 50-80 ksi) | Strength of the steel wire before PVC coating. Influences structural load-bearing capacity. |

| Adhesion Strength (PVC to Wire) | Excellent (no peeling/cracking) | Tested via bending or impact tests to ensure long-term integrity of the coating. |

| Operating Temperature Range | -30°C to +70°C | Range where PVC coating maintains optimal flexibility and integrity without degradation. |

| UV Resistance | High (stabilized PVC) | Utilizes UV inhibitors in the PVC formulation to prevent degradation and fading from sunlight. |

These parameters are critical in specifying pvc coated wire mesh for applications ranging from perimeter security and animal containment to architectural elements and industrial guarding. Compliance with international standards ensures material quality and performance reliability.

Key Technical Advantages

The engineered properties of pvc coated wire mesh provide a multitude of technical advantages that make it a preferred material for demanding applications across various industries.

- Exceptional Corrosion Resistance: The PVC coating acts as a robust barrier, protecting the underlying steel from moisture, chemicals, salts, and environmental pollutants. This significantly extends the service life, especially in coastal, industrial, or chemically exposed environments where untreated or galvanized steel would rapidly degrade. The initial pre-treatment (galvanization or phosphating) further enhances this resistance.

- Superior UV Stability: High-grade PVC formulations include UV inhibitors that prevent the coating from becoming brittle, cracking, or fading when exposed to prolonged sunlight. This ensures the aesthetic appeal and protective integrity of the mesh over many years, crucial for outdoor installations.

- Enhanced Durability and Impact Resistance: The resilient PVC layer absorbs minor impacts and abrasions, protecting the steel wire from damage that could initiate corrosion. This makes the mesh ideal for areas prone to wear and tear, such as animal enclosures or public fencing.

- Aesthetic Versatility: Available in a wide range of colors (e.g., green, black, white, blue), pvc coated wire mesh can be seamlessly integrated into various landscapes and architectural designs, offering both functionality and visual appeal. This broadens its application from purely utilitarian to decorative and architectural contexts.

- Low Maintenance Requirements: Due to its corrosion and weather resistance, PVC coated mesh requires minimal upkeep compared to conventional metal meshes that may need periodic painting or rust treatment. This translates into significant long-term cost savings for asset owners.

- Safety and Comfort: The smooth, plastic-coated surface eliminates sharp edges often found on bare metal mesh, making it safer for handling and for use in areas accessible to humans and animals. This is particularly beneficial for playgrounds, gardens, and animal housing.

- Cost-Effectiveness over Lifetime: While the initial cost of pvc coated wire mesh might be slightly higher than plain galvanized mesh, its extended lifespan and reduced maintenance costs often result in a lower total cost of ownership (TCO) over the product's entire service life, offering a strong return on investment.

These advantages collectively position pvc coated wire mesh as a premium choice for applications demanding long-term performance, minimal maintenance, and aesthetic integration.

Application Scenarios

The robust characteristics of pvc coated wire mesh lend themselves to a vast array of application scenarios across various sectors. Its versatility ensures effective solutions for containment, protection, and demarcation.

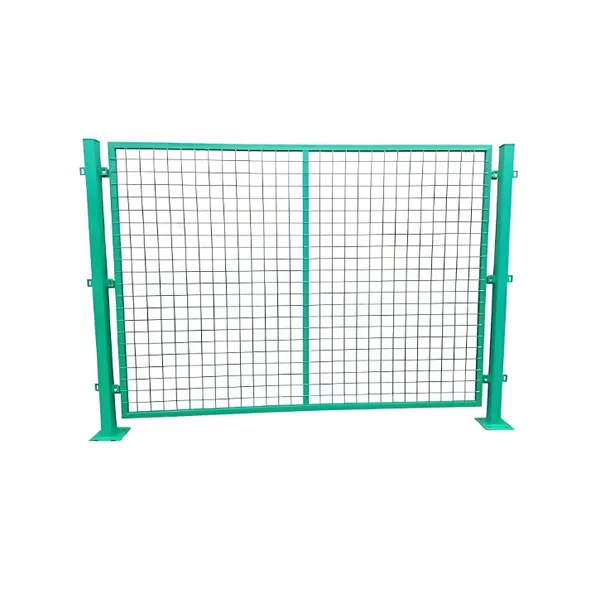

- Perimeter Security Fencing: Widely used for security fences around industrial facilities, government properties, schools, airports, and private estates. The durable coating ensures long-term integrity, even in exposed conditions, offering reliable intrusion deterrence.

- Agricultural and Animal Enclosures: Ideal for livestock fencing, poultry coops, dog runs, and garden protection. The corrosion resistance ensures non-toxic, long-lasting enclosures, while the smooth PVC surface prevents injury to animals. For example, a 2-inch x 2-inch mesh with a 2.5mm (12 gauge) coated wire is commonly used for larger animals, offering robust containment.

- Garden and Landscaping: Utilized for trellises, plant supports, protective barriers against pests, and decorative garden borders. The green or black PVC coating blends aesthetically with natural environments.

- Industrial and Machine Guarding: In manufacturing plants, it forms protective screens and machine guards, preventing accidental contact with moving parts while allowing visibility. Its durability withstands harsh industrial conditions.

- Construction and Civil Engineering: Can be used for temporary site fencing, erosion control (gabion applications), and reinforcing concrete where a flexible, corrosion-resistant mesh is needed. Small mesh sizes of 1/2" x 1/2" are effective for screening aggregates.

- Sports and Recreational Areas: Employed in tennis court fencing, baseball backstops, and perimeter fencing for parks, providing safety and durability under constant public use and environmental exposure.

- Marine and Coastal Applications: Due to its exceptional resistance to salt spray and humidity, it's suitable for marine environments, such as aquaculture cages or coastal barriers, where other metals would quickly corrode.

These diverse applications underscore the adaptability and reliability of pvc coated wire mesh as a superior material choice, capable of performing in the most demanding settings.

Vendor Comparison and Selection Criteria

Choosing the right supplier for pvc coated wire mesh is a critical decision that impacts project success, product longevity, and overall cost-effectiveness. A thorough evaluation of potential pvc coated wire mesh manufacturers is essential.

Key Criteria for Vendor Evaluation:

- Quality Certifications and Compliance: Verify adherence to international quality management systems (e.g., ISO 9001) and product-specific standards (e.g., ASTM F668 for PVC-coated chain-link fence, relevant EN standards). Look for evidence of consistent testing and quality assurance protocols.

- Manufacturing Capabilities and Technology: Assess the manufacturer's ability to produce desired volumes and custom specifications. Advanced automation in welding and coating processes often indicates superior product consistency and quality.

- Material Traceability and Quality: Inquire about the source of raw materials (steel wire, PVC powder). Reputable manufacturers ensure traceability and use only virgin, UV-stabilized PVC resins for optimal performance.

- Customization Options: Evaluate flexibility in offering custom wire gauges, mesh sizes, panel dimensions, and color choices to meet unique project requirements.

- Lead Times and Logistics: Understand typical production lead times, shipping capabilities, and ability to handle large or urgent orders efficiently. Global logistical expertise is a plus for international buyers.

- Customer Support and Technical Assistance: A responsive and knowledgeable sales and technical support team is invaluable for pre-sales consultation, order tracking, and post-sales queries.

- Warranty and After-Sales Service: Clear warranty statements and commitment to after-sales support instill confidence in product longevity and manufacturer accountability.

- Reputation and Experience: Look for a proven track record, positive customer feedback, and long-standing relationships with key clients. A manufacturer with many years in the industry often brings unparalleled expertise.

Hypothetical Vendor Comparison:

| Feature | Vendor A (Premium) | Vendor B (Standard) | Vendor C (Budget) |

|---|---|---|---|

| Quality Certifications | ISO 9001, ASTM F668, EN 10223 | ISO 9001 | Basic QC, no external certs |

| Core Wire Material | Hot-Dip Galvanized Low Carbon Steel (ASTM A123) | Electro-Galvanized Low Carbon Steel | Black Annealed Steel |

| PVC Coating Quality | Virgin UV-Stabilized, min. 0.6mm thick | Recycled/Blended, min. 0.4mm thick | Variable, thinner coating |

| Customization | Extensive (mesh, gauge, color, dimensions) | Moderate (standard options) | Limited (fixed sizes/colors) |

| Warranty | 15-20 years | 5-10 years | 1-2 years or none |

| Lead Time (Average) | 2-4 weeks | 3-6 weeks | 4-8 weeks |

By carefully evaluating these factors, buyers can identify pvc coated wire mesh manufacturers that best align with their project requirements, budget, and long-term performance expectations.

Customized Solutions

The ability to provide customized pvc coated wire mesh panels and rolls is a significant advantage offered by leading manufacturers. Tailored solutions ensure optimal fit, function, and aesthetic integration for unique project specifications.

Areas of Customization:

- Wire Diameter and Gauge: Specific requirements for strength and rigidity can be met by adjusting the core steel wire diameter and the overall coated wire diameter. This allows for fine-tuning the mesh's load-bearing capacity and resilience.

- Mesh Opening Size: Custom mesh apertures (square, rectangular) can be fabricated to control visibility, prevent passage of specific animals or objects, or meet structural design needs. Common examples include fine mesh for pest control or larger openings for aesthetic fences.

- Panel and Roll Dimensions: Beyond standard sizes, manufacturers can produce pvc coated wire mesh panels or rolls in bespoke widths and lengths, minimizing waste and simplifying installation for complex layouts.

- Custom Colors: While green and black are standard, PVC can be dyed to match specific corporate branding, architectural palettes, or environmental requirements, enhancing project aesthetics.

- Pre-treatment Options: Depending on the severity of the operating environment, customers can specify additional pre-treatment, such as heavier galvanization (e.g., hot-dip galvanized per ASTM A123) prior to PVC coating for enhanced corrosion protection.

- Edge Treatments and Fabrication: Custom edging, bent panels, or integrated fastening points can be provided to facilitate easier installation and improve safety.

These customization options allow clients to procure pvc coated wire mesh that is perfectly aligned with their project's technical, functional, and aesthetic demands, resulting in more efficient installations and superior long-term performance.

Application Case Studies

Real-world application demonstrates the tangible benefits and reliability of pvc coated wire mesh in diverse and demanding environments.

Case Study 1: Perimeter Security for a Chemical Plant

A major petrochemical complex required a robust, corrosion-resistant perimeter fence that could withstand harsh industrial atmospheres and potential chemical splashes. Traditional galvanized fencing showed signs of degradation within a few years. They opted for heavy-gauge pvc coated wire mesh panels (4.0mm coated wire, 50x50mm mesh) with a hot-dip galvanized core. The PVC coating, in a dark green color, provided exceptional resistance to acidic and alkaline aerosols prevalent in the environment, while also blending with the natural buffer zones. After 7 years, the fencing demonstrated no signs of coating deterioration or underlying steel corrosion, significantly outperforming previous installations and reducing maintenance costs by an estimated 60%.

Case Study 2: Agricultural Animal Enclosure in a Coastal Region

An agricultural client operating near the coast needed durable fencing for free-range poultry and small livestock. The constant exposure to salt-laden air and high humidity rapidly corroded standard wire mesh. The solution involved utilizing pvc coated wire mesh with a 2.5mm coated wire and 25x25mm mesh, featuring a specialized marine-grade PVC formulation with enhanced UV and salt-spray resistance. The smooth finish also ensured the safety of the animals. This installation has maintained its structural integrity and aesthetic appeal for over 10 years, providing a secure and humane enclosure without requiring replacement or extensive repairs, unlike previous fencing attempts.

Case Study 3: Urban Public Park Development

A city municipality undertaking a large public park renovation project sought fencing for sports fields, garden beds, and pedestrian pathways. Key requirements included durability, safety, and aesthetic integration with the park's natural environment. They selected various sizes of pvc coated wire mesh, primarily in green, for different applications. For sports fields, a heavier gauge 50x50mm mesh was used, while finer 15x15mm mesh was deployed for garden protection. The smooth, vibrant PVC coating not only contributed to the park's visual appeal but also provided a safe barrier for children and visitors, eliminating the risk of cuts from exposed wire. The low maintenance aspect was also a significant factor for the municipal budget.

Trustworthiness: FAQ, Lead Time, Warranty & Support

Building trust with B2B clients requires transparency regarding product information, logistics, and post-purchase support. This section addresses common queries and outlines our commitment to customer satisfaction for pvc coated wire mesh products.

Frequently Asked Questions (FAQ):

- Q: What is the typical service life of PVC Coated Wire Mesh?

- A: With proper installation and in typical environmental conditions, high-quality pvc coated wire mesh is designed to last 10-20 years or more, thanks to its superior corrosion and UV resistance. Service life can vary based on specific environmental severity and maintenance.

- Q: Can the PVC coating be damaged, and how does it affect performance?

- A: While highly durable, severe mechanical impact can damage the PVC coating. Small, localized damage typically does not compromise the overall corrosion resistance significantly, especially if the core wire is galvanized. For larger areas of damage, repair kits or patches can be applied to restore protection.

- Q: Is PVC Coated Wire Mesh environmentally friendly?

- A: Modern PVC formulations are free from heavy metals and phthalates, and many manufacturers are actively exploring sustainable practices. The extended lifespan of the product also contributes to environmental benefits by reducing the need for frequent replacement and associated resource consumption.

- Q: What are the common applications for different mesh sizes?

- A: Smaller meshes (e.g., 1/4" to 1/2") are often used for pest control, garden barriers, and machine guards. Medium meshes (e.g., 1" to 2") are versatile for animal enclosures and general fencing. Larger meshes (e.g., 2" to 4") are typically for heavy-duty security fencing, agricultural boundaries, or structural support in specific applications.

Lead Time and Fulfillment:

Our standard lead time for typical orders of pvc coated wire mesh ranges from 3 to 6 weeks, depending on product specification, order volume, and current production schedules. For highly customized solutions or exceptionally large orders, lead times may be extended and will be communicated clearly during the quotation process. We maintain efficient logistics partnerships to ensure timely and secure delivery globally, including detailed tracking and responsive communication throughout the shipping process. Expedited options may be available upon request for urgent project requirements.

Warranty Commitments:

We stand behind the quality of our pvc coated wire mesh products with a comprehensive warranty against manufacturing defects and premature degradation of the PVC coating. Our standard warranty typically covers 10 to 15 years, ensuring that the product maintains its protective and aesthetic properties under normal use. Specific warranty terms will be provided with each quotation and may vary slightly based on the chosen product specification and environmental exposure. This commitment reflects our confidence in the durability and craftsmanship of our materials.

Customer Support Information:

Our dedicated customer support team is available to assist B2B clients with all aspects of their procurement process, from initial inquiry and technical consultation to order placement and after-sales service. For sales inquiries, technical specifications, custom quotes, or any support needs, please contact us via:

- Email: [insert company email address, e.g., sales@yiszhewiremesh.com]

- Phone: [insert company phone number, e.g., +123-456-7890]

- Website: [insert company website link, e.g., www.yiszhewiremesh.com/contact]

Our expert team is committed to providing prompt, professional, and accurate support to ensure your projects are successful.

Conclusion

PVC coated wire mesh stands as a testament to advanced material engineering, offering a compelling blend of strength, durability, and aesthetic versatility. Its ability to provide superior corrosion resistance, UV stability, and minimal maintenance makes it an indispensable choice for a wide array of B2B applications, from critical infrastructure protection to sustainable agricultural solutions. By understanding its detailed manufacturing processes, technical specifications, and myriad application benefits, businesses can confidently leverage this material to achieve long-lasting, cost-effective, and high-performance outcomes in their projects.

Investing in high-quality pvc coated wire mesh from reputable manufacturers ensures not only compliance with stringent industry standards but also delivers exceptional value over the product's extended service life. As industries continue to evolve, the demand for resilient and adaptive materials will only grow, solidifying the position of PVC coated wire mesh as a vital component in modern industrial and environmental design.

References

- American Society for Testing and Materials (ASTM) Standards for Wire Mesh and Coatings.

- International Organization for Standardization (ISO) 9001:2015 for Quality Management Systems.

- European Standards (EN) for Steel Wire and Wire Products.

- "Corrosion Protection of Steel Structures," NACE International (National Association of Corrosion Engineers).

- "PVC Handbook," by Edward J. Wickson, Society of Plastics Engineers.

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025