Aug . 26, 2025 04:20 Back to list

Durable Bulk Roofing Nails: Wholesale Prices & Quality.

Navigating the Dynamics of Bulk Roofing Nails: Industry Trends and Essential Specifications

The global construction sector's continuous evolution necessitates high-performance fastening solutions, particularly in roofing applications. The demand for resilient, long-lasting structures directly impacts the market for bulk roofing nails, driving innovations in material science, manufacturing processes, and coating technologies. As a critical component in ensuring the structural integrity and weather resistance of roofs, the selection of appropriate roofing nails is paramount for architects, contractors, and procurement specialists.

Current industry trends highlight a shift towards enhanced corrosion resistance, increased pull-out strength, and environmental sustainability in manufacturing. The availability of diverse options, from galvanized to stainless steel variations, reflects the nuanced requirements of different climatic conditions and roofing materials. Understanding the technical specifications and application scenarios is crucial for optimizing project longevity and cost-effectiveness. Furthermore, competitive pricing strategies for roofing nails for sale and managing the overall cost of roofing nails are key considerations for large-scale construction projects.

Precision Manufacturing of Screw Roofing Nails

The production of high-quality bulk roofing nails, particularly the specialized Screw Roofing Nail, involves a meticulously controlled process designed to ensure superior performance and longevity. Our manufacturing process integrates advanced metallurgical techniques with stringent quality control, adhering to international standards such as ISO 9001 for quality management and ANSI standards for dimensional accuracy.

Process Flow Overview:

- Material Selection & Preparation: High-carbon steel wire rods (typically SAE 1018 to 1022) are selected for their optimal balance of strength and ductility. For enhanced corrosion resistance, stainless steel grades (e.g., 304, 316) or electro-galvanized/hot-dip galvanized wire are utilized. These materials undergo rigorous inspection to confirm chemical composition and mechanical properties.

- Wire Drawing: The raw wire rod is drawn through a series of dies to achieve the precise diameter required for the specific nail gauge. This process increases tensile strength and refines the material's grain structure.

- Cold Heading & Forming: Using high-speed cold heading machines, the wire is cut to length, and one end is formed into the desired head shape (e.g., umbrella head, flat head) while the other end is pointed. This cold forging process ensures high dimensional accuracy and enhances material density at stress points.

- Shank Threading (for Screw Roofing Nails): Unlike common smooth or ring shank nails, our Screw Roofing Nails undergo a specialized threading process. This involves rolling or cutting helical threads onto the nail shank, which significantly increases pull-out resistance by creating a tighter, screw-like grip in the substrate.

- Surface Treatment & Coating: Depending on the application, nails are either electro-galvanized (for moderate corrosion resistance, typically 3-5 microns zinc coating), hot-dip galvanized (for superior corrosion resistance, 40-80 microns zinc coating, conforming to ASTM A153), or polymer coated. This process ensures durability and extends service life significantly, often exceeding 50 years in benign environments.

- Quality Control & Testing: Throughout the process, nails are subjected to various tests including tensile strength, shear strength, bending resistance, coating thickness, and salt spray corrosion testing (ASTM B117) to ensure adherence to specified performance metrics.

- Packaging: Finished nails are counted, weighed, and packaged in bulk quantities, ready for distribution as bulk roofing nails. Packaging is designed to prevent damage during transit and storage.

The target industries for these high-performance fasteners include petrochemical, metallurgy, water supply & drainage, and general construction, where superior corrosion resistance and fastening strength are critical. Our screw roofing nails offer demonstrable advantages in typical application scenarios, such as enhanced energy efficiency through improved insulation integrity and superior resistance to environmental degradation.

Technical Specifications and Performance Metrics

Understanding the detailed technical specifications of bulk roofing nails is crucial for ensuring product suitability and compliance with project requirements. Our Screw Roofing Nails are engineered to provide exceptional performance under various environmental and structural stresses.

Product Specification Table: Screw Roofing Nail

| Parameter | Specification | Relevant Standard |

|---|---|---|

| Material | High-Carbon Steel (SAE 1022), Stainless Steel (304, 316) | ASTM A510, ASTM A276 |

| Head Type | Umbrella Head, Flat Head, Large Flat Head | Industry Standard |

| Shank Type | Screw/Helical Threaded Shank | Enhanced Pull-out Resistance |

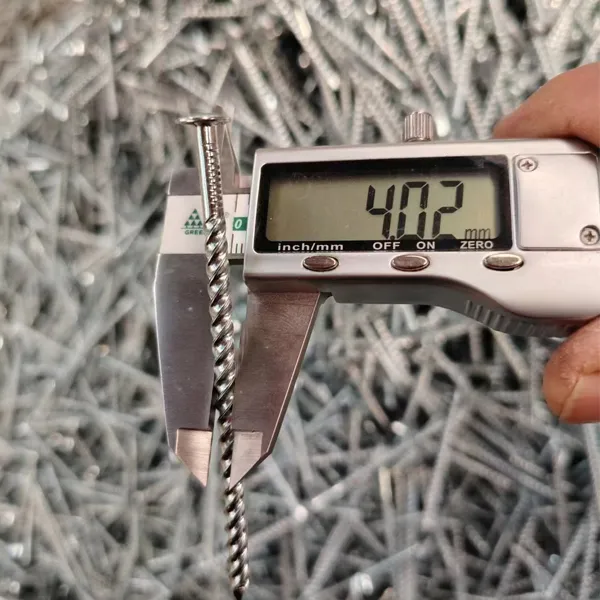

| Diameter (Gauge) | 2.8mm - 4.2mm (9-12 Gauge) | ANSI B18.6.1 |

| Length | 25mm - 100mm (1" - 4") | Industry Standard |

| Surface Treatment | Electro-Galvanized, Hot-Dip Galvanized, Stainless Steel, PVC Coated | ASTM A153, ASTM B695, ASTM B117 |

| Tensile Strength | ≥ 600 MPa (for Steel variants) | ASTM F1667 |

| Shear Strength | ≥ 350 MPa (for Steel variants) | ASTM F1667 |

| Pull-out Resistance | Significantly higher than smooth/ring shank nails (up to 2-3x) | Internal Testing, Industry Benchmarks |

The helical threading on our screw roofing nails is a key engineering differentiator, ensuring superior withdrawal resistance crucial for regions prone to high winds or seismic activity. This design feature minimizes roof uplift and extends the effective service life of roofing materials. Our comprehensive testing protocols guarantee that each batch of bulk roofing nails meets or exceeds these stringent performance benchmarks, ensuring reliability for your projects.

Versatile Application Scenarios for Roofing Nails

The versatility of high-quality bulk roofing nails makes them indispensable across a broad spectrum of construction and industrial applications. From residential housing to massive infrastructure projects, the right roofing nail ensures secure, durable fastening of roofing materials.

- Residential Roofing: Ideal for securing asphalt shingles, felt, and underlayment to wooden decking. The screw shank provides enhanced grip, crucial for preventing shingle blow-off in high-wind zones.

- Commercial & Industrial Structures: Used in fastening metal roofing panels, corrugated sheets, and insulation boards to purlins or structural elements. Hot-dip galvanized options offer superior corrosion resistance in environments exposed to industrial pollutants.

- Agricultural Buildings: For barns, sheds, and animal shelters, where roofing needs to withstand harsh weather, chemical exposures, and provide long-term protection. Stainless steel variants are preferred for corrosive environments.

- Petrochemical Facilities: In these demanding environments, the combination of robust materials and superior coatings is critical. Our nails provide secure fastening for roofing and cladding on process buildings, ensuring structural integrity against potential corrosive fumes and extreme temperatures.

- Water Treatment Plants: Given constant exposure to moisture and chemicals, stainless steel bulk roofing nails are essential for non-corrosive fastening of roofing components, contributing to the longevity of critical infrastructure.

- Logistics & Warehousing: For securing large span roofing on warehouses and distribution centers, where reliability and resistance to environmental stress are paramount for protecting valuable goods.

In each scenario, the selection of the correct nail type and coating is paramount. Our extensive experience in providing roofing nails for sale to diverse sectors allows us to recommend optimal solutions, ensuring maximum performance and minimum total cost of roofing nails over the structure's lifetime.

Technical Advantages and Performance Differentiation

The technical superiority of our Screw Roofing Nails stems from meticulous design and manufacturing, offering distinct advantages over conventional fasteners. Our commitment to excellence is underscored by certifications such as ISO 9001 and adherence to ASTM standards, establishing us as an authoritative provider of bulk roofing nails.

- Superior Pull-Out Resistance: The helical shank design creates a robust, interlocking grip with the roofing substrate, significantly increasing resistance to withdrawal forces. This is crucial for high-wind areas, preventing costly roof damage and enhancing safety. Test data consistently shows 200-300% greater pull-out strength compared to smooth shank nails.

- Enhanced Corrosion Resistance: Our hot-dip galvanized and stainless steel options provide exceptional protection against rust and environmental degradation. Hot-dip galvanization, meeting ASTM A153 specifications, offers thick zinc coatings (typically 40-80 microns) that ensure decades of service life even in harsh, coastal, or industrial environments.

- Optimal Sealing Capability: The umbrella head design on many of our roofing nails, often complemented by a washer, provides a larger bearing surface and effectively seals the nail hole, preventing water ingress and protecting underlying structures from moisture damage.

- Durability and Longevity: Manufactured from high-tensile steel, these nails resist bending, shearing, and deformation under stress. This inherent strength, combined with advanced coatings, guarantees a service life matching or exceeding the roofing material itself, reducing maintenance costs and ensuring long-term structural integrity.

- Consistent Quality: Decades of experience in the wire mesh and fastening industry, coupled with rigorous in-house testing and third-party verification, ensure that every batch of bulk roofing nails consistently meets stringent quality and performance standards.

Vendor Comparison and Competitive Edge

In the competitive market for bulk roofing nails, discerning buyers critically evaluate vendors based on product quality, technical support, customization capabilities, and overall value. While numerous suppliers offer roofing nails for sale, not all adhere to the same rigorous standards.

Key Differentiators in Vendor Selection:

- Material Sourcing & Consistency: Our commitment to sourcing premium-grade steel and advanced coating materials ensures consistent product quality, differentiating us from vendors who may compromise on raw material integrity to reduce the cost of roofing nails.

- Advanced Manufacturing Technology: Investment in state-of-the-art cold heading and threading machinery allows for precision engineering, producing nails with superior dimensional accuracy and enhanced mechanical properties.

- Rigorous Quality Assurance: Our multi-stage QC process, including in-line inspections and batch testing, significantly reduces defect rates compared to less stringent manufacturers. Certifications from reputable bodies underscore our adherence to international standards.

- Customization & Technical Support: We offer tailored solutions for unique project specifications, backed by a team of technical experts who provide pre-sales consultation and post-sales support, a service often lacking with general distributors.

- Supply Chain Reliability: With robust inventory management and established logistics networks, we ensure timely delivery of bulk orders, minimizing project delays and enhancing overall operational efficiency for our clients.

Comparative Advantage Table: Our Screw Roofing Nails vs. Standard Nails

| Feature | Our Screw Roofing Nails | Standard Smooth Shank Nails |

|---|---|---|

| Shank Design | Helical Threaded (Screw Type) | Smooth, Cylindrical |

| Pull-out Resistance | Excellent (2-3x higher) | Moderate to Low |

| Wind Uplift Resistance | Superior | Limited |

| Corrosion Protection | Hot-Dip Galvanized, Stainless Steel, PVC Coated options (ASTM A153+) | Often Electro-Galvanized or None (limited durability) |

| Typical Service Life (Coated) | 50+ years | 10-20 years |

| Application Suitability | High-wind zones, heavy-duty roofing, corrosive environments | Light-duty, temporary, low-stress applications |

Customized Solutions for Specialized Roofing Requirements

Recognizing that no two construction projects are identical, we offer comprehensive customized solutions for bulk roofing nails. Our engineering team collaborates closely with clients to develop fasteners that meet precise performance specifications, unique material requirements, or specific aesthetic considerations.

- Material Customization: Beyond standard high-carbon steel and stainless steel, we can explore specialized alloys for extreme temperature resilience, specific chemical resistance, or non-magnetic properties.

- Dimensional Modifications: Custom lengths, diameters, head sizes, and point types can be manufactured to perfectly match atypical roofing materials or structural depths. This includes optimizing shank length for specific insulation thicknesses.

- Advanced Coatings: While hot-dip galvanization is standard, we can implement custom polymer coatings for specific color matching, enhanced UV resistance, or supplementary chemical protection for highly aggressive environments.

- Packaging & Delivery: Customized packaging options, including specific carton sizes, weight limits, or labeling, can be arranged to streamline your on-site logistics and inventory management.

- Performance Tuning: For projects with specific load-bearing or withdrawal resistance targets, we can adjust the thread profile and material hardness to achieve precise mechanical performance, verified through dedicated testing.

Our agile manufacturing capabilities and deep engineering expertise enable us to transition from concept to production efficiently, ensuring that even complex custom orders for roofing nails for sale are delivered on time and within budget, optimizing the overall cost of roofing nails for specialized applications.

Application Case Studies: Proven Performance in Real-World Scenarios

Our Screw Roofing Nails have been successfully deployed in numerous demanding projects globally, demonstrating their reliability and superior performance in diverse environmental conditions. These case studies underscore our capability as an authoritative supplier of bulk roofing nails.

Case Study 1: Coastal Industrial Facility, Gulf Coast Region

Challenge: A large petrochemical plant required roofing fasteners for its new processing unit buildings. The location, characterized by high humidity, salt-laden air, and frequent hurricane threats, demanded exceptional corrosion resistance and wind uplift performance. Previous fasteners experienced premature corrosion and structural failure.

Solution: We supplied 3.8mm x 75mm Hot-Dip Galvanized (ASTM A153 Class C) Screw Roofing Nails with an umbrella head and EPDM washers. The helical shank ensured maximum pull-out resistance against hurricane-force winds, while the thick zinc coating provided superior protection against marine corrosion.

Outcome: After five years, the roofing systems remain intact with no signs of fastener corrosion or structural compromise, even after weathering multiple tropical storms. The client reported significant savings on maintenance and replacement costs.

Case Study 2: High-Altitude Commercial Warehouse, Rocky Mountains

Challenge: Constructing a large warehouse at 2,500 meters required fasteners capable of withstanding extreme temperature fluctuations, heavy snow loads, and significant wind shear, all while securely fastening insulated metal panels.

Solution: We provided custom-length 4.2mm x 100mm Stainless Steel (304 grade) Screw Roofing Nails, specifically engineered for optimal thermal expansion compatibility with the metal panels and enhanced shear strength under heavy snow.

Outcome: The warehouse roof has successfully endured multiple severe winters, with no reports of fastener fatigue, material movement, or structural issues. The client lauded the specialized solution that addressed their unique environmental pressures.

Case Study 3: Agricultural Facility Renovation, Midwest USA

Challenge: An expansive livestock facility required a complete roofing overhaul with new corrugated steel sheets. The primary concerns were cost-effectiveness for bulk roofing nails, ease of installation, and moderate corrosion resistance against ammonia fumes from animal waste.

Solution: We supplied 3.5mm x 50mm Electro-Galvanized Screw Roofing Nails with a PVC-coated umbrella head, offering a balance of corrosion protection and economic viability. The screw thread facilitated rapid, secure installation.

Outcome: The project was completed ahead of schedule, with the client noting significant labor savings due to the nail's ease of use. The roof has remained robust, resisting localized corrosion from the ammonia-rich atmosphere, validating our cost-effective yet durable solution for their specific roofing nails for sale needs.

Frequently Asked Questions (FAQ)

Q: What makes Screw Roofing Nails superior to traditional smooth shank nails?

A: Screw Roofing Nails feature a helical threaded shank that creates a tighter, more secure grip within the roofing substrate. This design dramatically increases pull-out resistance, making them significantly more effective against wind uplift and shear forces compared to smooth shank nails.

Q: How do you ensure the corrosion resistance of your bulk roofing nails?

A: We offer multiple levels of corrosion protection. Our hot-dip galvanized nails adhere to ASTM A153 standards, providing a thick, durable zinc coating. For extreme conditions, we supply nails made from stainless steel grades (304, 316). All coatings undergo salt spray testing (ASTM B117) to verify their performance.

Q: Can I get customized bulk roofing nails for a specific project?

A: Absolutely. We specialize in providing customized solutions. Our engineering team can work with your specifications for material type, dimensions (length, diameter, head style), coating, and even specialized packaging to meet your unique project requirements. Contact our sales team to discuss your needs.

Q: What is the typical lead time for roofing nails for sale in bulk?

A: For standard bulk orders, our lead time typically ranges from 2-4 weeks, depending on order volume and specific product availability. Customized orders may require slightly longer. We prioritize efficient production and logistics to ensure timely delivery. Please consult our sales department for precise lead times for your specific order.

Q: What kind of warranty do you offer on your products?

A: We stand behind the quality of our Screw Roofing Nails. We offer a comprehensive warranty against manufacturing defects and material failures under normal usage conditions. The specific terms and duration of the warranty depend on the product type and application. Please refer to our official warranty policy document or contact customer support for details.

Lead Time, Fulfillment, and Customer Support

Our streamlined operational processes ensure efficiency from order placement to delivery for all bulk roofing nails.

- Lead Time: For standard orders of common sizes and finishes, expect a lead time of 2-4 weeks. Large-volume orders or custom specifications may extend this to 4-8 weeks. We maintain a strategic inventory to expedite urgent requirements.

- Fulfillment: Our logistics team manages domestic and international shipping, partnering with reputable carriers to ensure secure and timely delivery to your project site. We provide real-time tracking and dedicated support for all shipments.

- Warranty Commitments: All our Screw Roofing Nails are backed by an industry-leading warranty covering material and manufacturing defects. Our commitment reflects our confidence in the durability and quality of our products. Specific warranty details are provided with each order or upon request.

- Customer Support: Our dedicated customer service and technical support teams are available to assist with product selection, technical queries, order tracking, and any post-sales inquiries. We prioritize responsive and knowledgeable support to ensure your complete satisfaction.

Conclusion: The Foundation of Reliable Roofing

The performance of a roofing system hinges on the quality of its fasteners. Our Screw Roofing Nails represent the pinnacle of engineering and material science in the field of bulk roofing nails, offering unparalleled pull-out resistance, corrosion protection, and overall durability. By choosing our products, you invest in long-term structural integrity, reduced maintenance, and enhanced safety for your most critical assets. Our comprehensive range of roofing nails for sale, combined with flexible customization options and dedicated support, ensures that your project benefits from the optimal fastening solution at a competitive cost of roofing nails.

References

- American Society for Testing and Materials (ASTM International). ASTM A153/A153M, Standard Specification for Zinc Coating (Hot-Dip) on Iron and Steel Hardware.

- ISO (International Organization for Standardization). ISO 9001:2015, Quality management systems — Requirements.

- National Institute of Standards and Technology (NIST). Building and Fire Research Laboratory Reports on Fastener Performance.

- Roofing Industry Committee on Weather Issues (RICOWI). Wind Design for Low-Slope Roofs: Fastener Selection and Spacing.

- Construction Materials Research Council. Advanced Fastening Systems for Enhanced Structural Durability.

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025