Aug . 18, 2025 03:20 Back to list

Bulk Roofing Nails - Best Prices & Quality

Understanding High-Performance Screw Roofing Nails for Industrial Applications

In the realm of modern construction and infrastructure, the integrity of a structure often hinges on the quality of its foundational components. Among these, fasteners play a critically understated role, particularly in roofing applications where they endure constant exposure to harsh environmental elements. Our focus today is on bulk roofing nails, specifically the advanced Screw Roofing Nail, a product engineered to deliver superior holding power, enhanced durability, and exceptional resistance to uplift and shear forces. These specialized nails are not merely simple fasteners; they represent a pinnacle of metallurgical and manufacturing expertise, designed to meet the rigorous demands of industrial roofing, residential construction, and various specialized outdoor installations. Understanding their nuanced design, material composition, and application advantages is crucial for procurement managers, structural engineers, and contractors seeking optimal long-term performance and reduced maintenance costs.

The global market for roofing materials is evolving rapidly, driven by demand for more sustainable, resilient, and cost-effective solutions. This trend directly impacts the demand for fasteners, pushing manufacturers to innovate beyond traditional smooth-shank nails. Screw roofing nails, with their distinct threaded shanks, offer a significantly higher withdrawal resistance compared to conventional nails, making them indispensable for high-wind zones and areas prone to seismic activity. This enhanced performance translates into greater structural integrity and extended service life for roofing systems, ultimately contributing to the overall safety and longevity of buildings. Procurement professionals are increasingly looking for reliable suppliers offering bulk roofing nails that meet international standards and provide verifiable performance data, ensuring their investments yield optimal returns and comply with stringent building codes. This shift reflects a growing emphasis on lifecycle costs over initial purchase price, underscoring the value of high-performance fastening solutions in complex construction projects.

When considering roofing nails for sale, it's imperative to look beyond the initial purchase price and evaluate the total cost of ownership, which includes installation efficiency, long-term performance, and potential replacement costs. The specialized design of screw roofing nails minimizes the risk of nail pops and shingle blow-offs, common issues that can lead to premature roof degradation and costly repairs. Our Screw Roofing Nails are meticulously crafted to provide consistent performance across diverse climatic conditions, ensuring a secure and weather-tight seal. This reliability is paramount for large-scale construction projects and continuous manufacturing operations where downtime due to structural failure is unacceptable. The investment in high-quality fasteners like our bulk roofing nails is an investment in the overall resilience and longevity of your infrastructure. This approach not only safeguards assets but also enhances operational efficiency by reducing unplanned maintenance and ensuring compliance with stringent safety and performance standards.

Precision Manufacturing: The Journey of a Screw Roofing Nail

The manufacturing of high-quality bulk roofing nails is a sophisticated multi-stage process that combines advanced metallurgy with precision engineering. It begins with the selection of premium raw materials, typically high-carbon steel wire (e.g., SAE 1022 or equivalent), chosen for its tensile strength and ductility. Unlike traditional casting or forging methods which are unsuitable for nail production, our Screw Roofing Nails are produced using advanced cold-heading and roll-threading techniques. The wire is first drawn to the precise diameter, then fed into a cold-heading machine that shears the wire and forms the nail head in one rapid operation. This cold-forming process significantly enhances the material's strength and fatigue resistance by compressing the grain structure without applying heat, which could alter metallurgical properties adversely. Following the head formation, the shanks are then roll-threaded, creating the characteristic helical threads that provide superior grip and withdrawal resistance. This threading process is critical, as it dictates the nail's mechanical locking ability within the substrate. Each stage is meticulously monitored to ensure dimensional accuracy and structural integrity, laying the foundation for a reliable finished product.

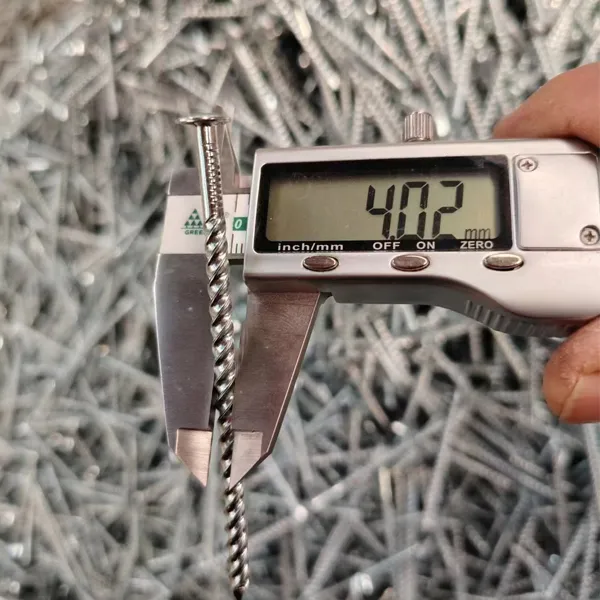

Post-forming, the nails undergo various finishing processes tailored to enhance their performance and extend their service life. This includes cleaning, annealing (if required for specific properties), and crucially, surface coating. Common coatings for bulk roofing nails include electro-galvanization, hot-dip galvanization (HDG), and specialized polymer coatings like black phosphate. Hot-dip galvanization, for instance, provides a thick, durable zinc coating that offers exceptional corrosion resistance, crucial for nails exposed to moisture and corrosive agents in environments such as coastal areas or industrial zones. Each batch undergoes rigorous quality control inspections at every stage. This includes dimensional checks using micrometers and calipers, hardness testing (e.g., Rockwell hardness), and pull-out strength tests to verify the withdrawal resistance. Adherence to international standards such as ASTM F1667 (Standard Specification for Driven Fasteners: Nails, Spikes, and Staples) and ISO 898-1 is non-negotiable, ensuring that every nail meets or exceeds industry benchmarks for performance and safety. These stringent protocols guarantee that our screw roofing nails deliver consistent, reliable performance in demanding applications, from petro-chemical facilities to advanced drainage systems, thereby contributing to significant operational savings.

The applicable industries for our high-quality bulk roofing nails are extensive, ranging from general construction, residential and commercial roofing, to specialized industrial applications like pre-engineered metal buildings, agricultural structures, and infrastructure projects in sectors such as petrochemical, metallurgy, and water treatment. In the petrochemical sector, for instance, superior corrosion resistance is paramount for fasteners used in roofing systems above chemical processing units, where corrosive fumes are prevalent. Our HDG screw roofing nails excel in such environments, providing long-term structural integrity and reducing the need for premature replacements. Similarly, in large-scale drainage systems, where exposure to moisture and various soil chemistries is constant, the durability and anti-corrosive properties of our nails ensure the longevity of attached components. The estimated service life of our hot-dip galvanized screw roofing nails, when properly installed according to industry guidelines, can exceed 50 years, significantly outperforming standard nails and contributing to substantial cost savings over the lifespan of a project due to minimized maintenance and replacement cycles. This long-term reliability is a key technical advantage, delivering robust structural connections and peace of mind for engineering teams.

Technical Specifications & Performance Data

Selecting the appropriate bulk roofing nails requires a thorough understanding of their technical specifications and how these parameters influence performance in various applications. Key specifications include gauge (nail diameter), length, head diameter, shank type (smooth, ring, screw), and coating type. For instance, a larger gauge nail provides greater shear strength, while a longer nail offers better penetration and pull-out resistance, especially through thicker materials or multiple layers. Our Screw Roofing Nails are meticulously engineered to optimal specifications, ensuring maximum efficacy for roofing applications. The screw shank design significantly increases the surface area in contact with the wood fibers, creating a mechanical lock that resists withdrawal forces far more effectively than smooth or even ring-shank nails. This is crucial for environments subject to high winds, such as coastal regions or hurricane-prone areas, where uplift forces can exert immense stress on roofing components, potentially leading to catastrophic failures and substantial financial losses if inadequate fasteners are used.

To aid in procurement and project planning, we provide comprehensive data on the typical parameters for our bulk roofing nails. This table outlines the most common specifications, offering a quick reference for engineers and purchasing departments to match product capabilities with project requirements. Our nails are available in a range of sizes to accommodate various roofing materials, including asphalt shingles, wood shakes, slate, and metal roofing panels. The broad head design ensures maximum pull-through resistance, securing the roofing material firmly against the substrate. Furthermore, the sharp, diamond point facilitates easy penetration into dense materials, reducing splitting and ensuring a clean installation. Understanding these detailed specifications allows for precise selection, minimizing waste and optimizing the structural integrity of your roofing projects. For specific applications requiring unique dimensions or material properties, our team is equipped to provide tailored solutions and detailed technical consultations. This ensures that every project benefits from the most suitable and highest-performing fastening solution available.

Typical Specifications for Screw Roofing Nails

| Parameter | Typical Range/Value | Description/Benefit |

|---|---|---|

| Material | High-Carbon Steel (SAE 1022) | Ensures superior tensile strength and durability, preventing bending during installation. |

| Gauge (Shank Diameter) | 8 GA - 12 GA (approx. 2.77mm - 4.19mm) | Optimized for shear strength and material penetration across various roofing substrates. |

| Length | 1" - 2" (approx. 25mm - 50mm) | Variety for different shingle thicknesses, multi-layer applications, and substrate depths. |

| Head Diameter | 3/8" - 7/16" (approx. 9.5mm - 11.1mm) | Large, flat head for maximum pull-through resistance, securing shingles effectively. |

| Shank Type | Screw Threaded | Superior withdrawal resistance, minimizes nail pop and enhances long-term stability. |

| Coating Options | Electro-Galvanized (EG), Hot-Dip Galvanized (HDG), Black Phosphate | Enhanced corrosion resistance for diverse environments, extending service life. |

| Withdrawal Resistance (Average) | Up to 250% higher than smooth shank nails | Crucial for high-wind and seismic zones, ensuring structural integrity under stress. |

| Corrosion Resistance (HDG) | ASTM A153 Compliant | Ensures longevity in harsh outdoor conditions, preventing rust and material degradation. |

Regarding the cost of roofing nails, it's essential to analyze the overall value proposition. While screw roofing nails may have a slightly higher upfront cost per unit compared to standard smooth or ring shank nails, their superior performance, extended service life, and reduced failure rates result in significant long-term savings. The cost savings come from fewer repairs, reduced labor for re-nailing, and avoidance of property damage due to roof failure. For large-scale projects, the efficiency of installation, coupled with the enhanced reliability, translates into substantial operational cost reductions. Furthermore, our commitment to bulk sales enables us to offer competitive pricing for high volumes, making these premium fasteners an economically viable choice for major contractors and distributors. Investing in quality fasteners like our bulk roofing nails directly contributes to lower life-cycle costs for any structure, providing a stronger return on investment compared to cheaper, less reliable alternatives.

Applications, Advantages, and Customization

Our bulk roofing nails are designed for diverse applications, ensuring optimal performance across various roofing systems and environmental conditions. The primary application is, of course, securing roofing materials such as asphalt shingles, cedar shakes, slate tiles, and corrugated metal sheets to roof decking. Their superior withdrawal resistance makes them ideal for critical installations in high-wind regions, ensuring shingles remain fastened even under extreme uplift pressures. Beyond standard roofing, these nails are also extensively used in securing sheathing, underlayment, and trim in residential and commercial buildings. In industrial settings, they find use in fastening insulation boards, membrane systems, and various other components where a robust and long-lasting connection is essential. The ability of screw shank nails to resist backing out, often referred to as "nail creep," is a significant advantage, particularly in structures exposed to thermal expansion and contraction cycles, which can loosen traditional fasteners over time. This ensures sustained structural integrity and reduces maintenance demands, contributing to the overall durability of the entire roof system.

The technical advantages of our Screw Roofing Nails are multifaceted. Firstly, their threaded shank provides approximately 2-3 times the withdrawal resistance of smooth shank nails, making them invaluable for structural integrity in challenging environments. Secondly, the large, flat head design distributes the load over a wider area, preventing pull-through on softer materials and enhancing the overall fastening strength. Thirdly, the range of coating options, particularly hot-dip galvanization, offers unparalleled corrosion resistance, extending the product's lifespan and reducing the risk of rust stains on roofing materials. This anti-corrosion property is particularly beneficial in aggressive environments such as those found in coastal construction or industrial facilities processing chemicals, where standard fasteners would quickly degrade. Lastly, the ease of installation, whether by hand or with pneumatic nailers, ensures efficiency on the job site without compromising the integrity of the connection. These combined advantages translate into a lower total cost of ownership and enhanced safety for any construction project utilizing our bulk roofing nails.

We understand that specific projects often require tailored solutions. As a leading manufacturer of bulk roofing nails, we offer extensive customization options to meet unique project demands. This includes variations in material grade (e.g., stainless steel for extreme corrosion resistance in highly corrosive industrial settings), specific gauge and length combinations, head styles (e.g., checkered heads for better grip with hammer), and a wider array of specialized coatings (e.g., polymer coatings for color matching or enhanced UV resistance, often used in architectural roofing). For large volume orders or specialized industrial applications, we can collaborate closely with your engineering team to design and produce nails that perfectly align with your performance specifications. Our flexible manufacturing capabilities and in-house technical expertise allow us to deliver bespoke solutions efficiently, ensuring that even the most niche requirements for roofing nails for sale are met with precision and quality. This dedication to customization underscores our commitment to being a comprehensive solution provider in the fastener industry, capable of meeting diverse and stringent project demands.

Product Comparison: Choosing the Right Roofing Nail

When sourcing bulk roofing nails, understanding the distinctions between various types is crucial for making an informed decision that balances performance, longevity, and cost-effectiveness. While smooth shank nails are the most common and least expensive, their withdrawal resistance is minimal, making them unsuitable for high-stress applications or regions prone to severe weather. Ring shank nails offer improved grip due to their annular rings but still fall short of the superior holding power provided by screw shank nails, especially when subjected to dynamic loads or thermal cycling. Screw roofing nails, with their helical threads, embed into the substrate like a screw, creating a powerful mechanical interlock that significantly resists pull-out. This table provides a comparative analysis, highlighting the key differences and suitability of each type for various roofing needs, especially for those evaluating roofing nails for sale options. The selection process should consider the local building codes, expected weather conditions, and the specific roofing material being used, as these factors dictate the required fastener performance and ultimately, the long-term integrity of the structure.

Comparative Analysis of Roofing Nail Types

| Feature | Smooth Shank Nail | Ring Shank Nail | Screw Roofing Nail (Our Product) |

|---|---|---|---|

| Shank Design | Plain, smooth cylindrical body | Annular rings along the shank for friction grip | Helical screw threads, forming a tight mechanical interlock |

| Withdrawal Resistance | Low, prone to backing out over time | Medium, improved friction, but can loosen under dynamic loads | High (Superior, Mechanical Lock), highly resistant to pull-out forces |

| Resistance to Nail Pop | Poor, common issue leading to shingle damage | Fair, better than smooth, but still susceptible | Excellent, maintains tight seal preventing pops and leaks |

| Typical Cost | Lowest upfront cost | Medium cost, slight premium over smooth | Higher (Justified by Performance), lower lifecycle cost |

| Ideal Application | Temporary fixation, light-duty, non-critical applications | General roofing in moderate climates, interior sheathing | High-wind zones, heavy-duty roofing, critical structures, industrial applications |

| Corrosion Protection | Often uncoated or minimally electro-galvanized (EG) | EG or Hot-Dip Galvanized (HDG) options available | Full range including robust HDG for extreme environments, specific polymer coatings |

This comparative analysis clearly illustrates why investing in screw roofing nails, despite their potentially higher initial cost of roofing nails, offers superior long-term value. Their unparalleled withdrawal resistance and longevity reduce the need for costly re-roofing or repairs, providing significant economic benefits over the lifecycle of a structure. For project managers and procurement specialists, this means a reduction in operational expenditures and an increase in structural resilience. We advocate for a thorough cost-benefit analysis that extends beyond the immediate purchase price, encompassing durability, installation efficiency, and future maintenance requirements. Our bulk roofing nails are engineered to optimize this long-term value, making them the preferred choice for discerning clients who prioritize safety, performance, and sustainability in their construction endeavors. We also ensure clear labeling and packaging for all our products, facilitating easy identification and inventory management on busy construction sites, thereby streamlining logistical processes for large-scale operations.

Our Commitment: Authority, Trust, and Support

With decades of experience in the wire mesh and fastener industry, our company has established itself as a trusted authority in delivering high-quality industrial solutions. Our commitment to excellence is underpinned by rigorous adherence to international quality management systems, including ISO 9001 certification, which governs our entire manufacturing process from raw material sourcing to final product inspection. This certification is a testament to our consistent production of reliable bulk roofing nails that meet the most demanding performance criteria. We pride ourselves on transparent operations, providing comprehensive documentation and verifiable test data for all our products. Our extensive service history, spanning numerous successful projects across various sectors including construction, industrial infrastructure, and specialized engineering, speaks volumes about our reliability and expertise. We don't just supply products; we partner with our clients to ensure their projects are successful, offering technical guidance and support every step of the way. This established track record builds trust and reinforces our position as a leading supplier of roofing nails for sale in the global market.

Our dedication to client satisfaction extends beyond product quality to encompass robust customer support and efficient logistics. We maintain substantial inventory of standard bulk roofing nails to ensure rapid order fulfillment, and our production facilities are agile enough to manage large, custom orders with competitive lead times. Our typical delivery cycle for standard products is 7-14 business days, while customized solutions may vary depending on complexity and volume, with clear communication provided throughout the process. Furthermore, we stand behind the quality of our Screw Roofing Nails with a comprehensive warranty against manufacturing defects. This warranty reflects our confidence in the durability and performance of our products, providing peace of mind for our clients and underscoring our commitment to product excellence. In the unlikely event of any issue, our dedicated customer service team is readily available to provide prompt assistance and resolution, ensuring minimal disruption to your operations. This holistic approach to service and product delivery reinforces our trustworthiness in the market, making us a preferred partner for roofing nails for sale globally.

Frequently Asked Questions (FAQ)

Q: What makes screw roofing nails superior to standard nails?

A: Screw roofing nails feature a helical threaded shank that creates a mechanical lock with the substrate, offering significantly higher withdrawal resistance (2-3 times more) than smooth or even ring shank nails. This prevents nail pops and ensures superior holding power, especially in high-wind areas or structures prone to movement, contributing to a longer roof lifespan.

Q: Are your bulk roofing nails available with different corrosion resistance options?

A: Yes, we offer several coating options including Electro-Galvanized (EG) for general outdoor use, and Hot-Dip Galvanized (HDG) for superior corrosion resistance in harsh, humid, or corrosive environments like coastal regions or industrial sites. We can also discuss specialized polymer coatings for specific project needs, ensuring optimal performance in diverse conditions.

Q: What is the typical lead time for large orders of bulk roofing nails?

A: For standard products, our typical delivery cycle is 7-14 business days, depending on volume and destination. For large or customized orders, the lead time can vary based on complexity and specific requirements, but we always provide a clear, estimated delivery schedule at the time of order confirmation and keep clients updated on progress to ensure seamless project execution.

Q: Can these nails be used with pneumatic nail guns?

A: Our Screw Roofing Nails are designed to be compatible with most standard pneumatic roofing nailers, ensuring efficient and rapid installation on job sites. It is always recommended to check your specific nailer's compatibility for the nail gauge and length to ensure optimal performance and safety during operation.

Q: Do you provide certifications or test reports for your roofing nails for sale?

A: Absolutely. As an ISO 9001 certified manufacturer, we can provide relevant certifications, material test reports, and performance data (e.g., pull-out strength, salt spray test results for coatings, shear strength) upon request. This ensures complete transparency and compliance with stringent project specifications and industry standards, giving our clients full confidence in our products.

Authoritative References

- ASTM F1667 - 17: Standard Specification for Driven Fasteners: Nails, Spikes, and Staples. ASTM International, West Conshohocken, PA, 2017.

- ISO 9001: Quality Management Systems – Requirements. International Organization for Standardization, Geneva, Switzerland.

- National Roofing Contractors Association (NRCA) Roofing Manual: Steep-Slope Roof Systems. NRCA, Rosemont, IL.

- Florida Building Code (FBC) Requirements for Wind Resistance in Roofing. Florida Department of Business and Professional Regulation.

- AITC Technical Note 20: Fastener Performance for Glued Laminated Timber. American Institute of Timber Construction.

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025