Aug . 17, 2025 03:20 Back to list

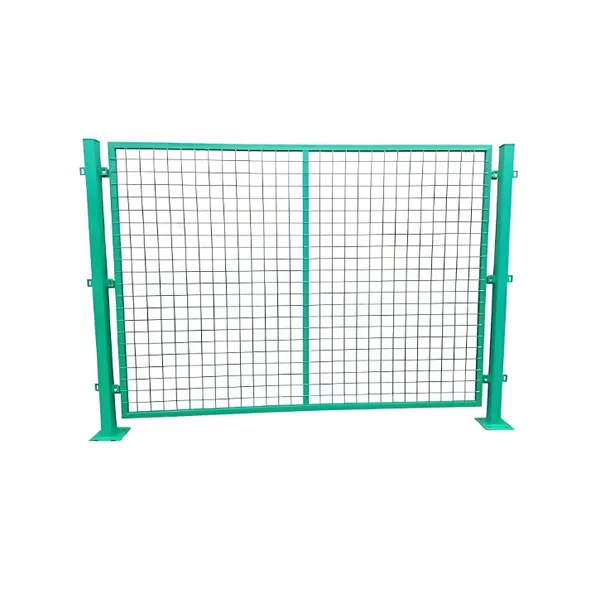

PVC Coated Wire Mesh: Durable Panels & Fencing Solutions

The Enduring Versatility of PVC Coated Welded Wire Mesh in Modern Infrastructure

In the realm of modern construction, agriculture, and security applications, the demand for resilient and long-lasting materials is paramount. Among the diverse range of solutions, PVC coated wire mesh stands out as a superior choice, offering unparalleled durability and aesthetic appeal. This innovative material combines the inherent strength of steel with the robust protective qualities of a polyvinyl chloride (PVC) coating, resulting in a product highly resistant to corrosion, weathering, and general wear and tear. Its widespread adoption across various industries is a testament to its exceptional performance, particularly in environments where exposure to moisture, chemicals, or extreme temperatures would compromise untreated metals. The strategic application of PVC coating not only extends the product's service life but also provides a smooth, often colored, finish that integrates seamlessly into diverse architectural and natural landscapes, making it ideal for fencing, enclosures, and decorative panels. The manufacturing excellence behind these products ensures a consistent quality that meets rigorous international standards, providing B2B decision-makers with a reliable and cost-effective solution for their most demanding projects. This comprehensive overview delves into the intricate manufacturing processes, technical specifications, and expansive applications that solidify its position as a go-to material for durable infrastructure.

The market for pvc coated wire mesh continues to expand, driven by increasing global infrastructure development and a heightened focus on sustainable, low-maintenance materials. Industry reports indicate a steady growth trajectory, with projections emphasizing the rising demand in agricultural fencing, residential security, and public works projects. This growth is underpinned by the material's ability to offer a significant return on investment through reduced replacement and maintenance costs over its extensive lifespan. Unlike traditional galvanized mesh, the additional PVC layer provides an extra barrier against degradation, making it particularly valuable in coastal regions or areas with high humidity and pollution. Furthermore, the aesthetic flexibility offered by various color options makes it a preferred choice for projects where visual integration is as important as functional performance. As pvc coated wire mesh manufacturers innovate with advanced coating technologies and material compositions, the product's performance envelope continues to expand, offering even greater resistance to UV radiation and physical abrasion. This constant evolution ensures that the product remains at the forefront of material science for protective and structural applications, meeting the evolving needs of a dynamic global market.

Precision Engineering: The Manufacturing Journey of PVC Coated Welded Wire Mesh

The production of PVC Coated Welded Wire Mesh is a sophisticated multi-stage process that guarantees the material's superior quality and performance. It commences with the meticulous selection of high-grade steel wire, typically low-carbon steel, which undergoes a rigorous quality inspection to ensure its chemical composition and mechanical properties meet specified standards. This raw wire is then drawn through a series of dies to achieve the precise wire gauge required for the final product, a process that enhances its tensile strength and uniformity. Following this, the drawn wires are accurately cut and organized for the welding phase. Advanced automated welding machines employ resistance welding technology to fuse the horizontal and vertical wires at their intersections, forming a strong, rigid mesh structure with precise and consistent aperture sizes. This critical step ensures the structural integrity of the welded mesh, preventing unraveling or deformation under stress. The quality of welds is continuously monitored through inline inspection systems, maintaining strict adherence to international standards such as ASTM A185 for welded steel wire reinforcement or similar industry benchmarks for mesh integrity.

Once the bare welded mesh is formed, it undergoes a thorough cleaning and pre-treatment process essential for optimal PVC adhesion. This typically involves degreasing and phosphating, which removes any contaminants and creates a receptive surface for the coating. The mesh is then ready for the PVC coating application, which is the defining characteristic of PVC Coated Welded Wire Mesh. There are primarily two methods: hot-dip plastification or electrostatic spray coating. In the hot-dip method, the pre-heated mesh is immersed into a fluidized bed of PVC powder, which melts upon contact and forms a uniform, thick layer. Alternatively, electrostatic spraying involves charging the PVC powder and spraying it onto the grounded mesh, ensuring an even coating before the mesh is heated in an oven to cure and bond the PVC layer permanently. This curing process is crucial for achieving superior adhesion, preventing chipping, cracking, or peeling of the coating, even under harsh environmental conditions. Post-coating, each panel undergoes a final comprehensive inspection, assessing coating thickness, color uniformity, adhesion strength (e.g., via cross-hatch or impact tests), and overall dimensional accuracy. This stringent quality control at every stage ensures that the finished pvc coated wire mesh exhibits exceptional resistance to corrosion, UV radiation, and chemical exposure, contributing to a significantly extended service life compared to uncoated or simply galvanized alternatives, particularly in applications requiring robust anti-corrosion properties in saline or acidic environments.

Technical Specifications and Performance Metrics for PVC Coated Wire Mesh

Understanding the technical parameters of PVC Coated Welded Wire Mesh is crucial for selecting the appropriate product for specific industrial and commercial applications. These parameters directly influence the mesh's strength, durability, and suitability for various environmental conditions. Key specifications include the wire gauge, which refers to the diameter of the steel wire before coating, often expressed in SWG (Standard Wire Gauge) or millimeters. A lower gauge number indicates a thicker wire, signifying greater strength. Mesh opening, or aperture size, is another vital dimension, defining the spacing between the wires and influencing visibility, airflow, and containment capabilities. The PVC coating thickness is equally important, directly correlating with the product's resistance to corrosion and UV degradation; typically ranging from 0.2mm to 1.0mm or more, this layer serves as the primary protective barrier. Furthermore, the tensile strength of the underlying steel wire, measured in MPa (Megapascals), determines the mesh's resistance to stretching or breaking under tension, a critical factor for security and structural applications.

Manufacturers of pvc coated wire mesh often provide detailed specifications that adhere to national and international standards, ensuring consistent quality and performance. These standards might include ISO 9001 for quality management systems, or specific product standards like ASTM F668 for PVC coated chain-link fence fabric, which outlines requirements for coating adherence, thickness, and material composition. The adhesion of the PVC coating to the steel core is rigorously tested to prevent delamination, ensuring the long-term integrity of the protective layer. Lifespan expectations for high-quality pvc coated wire mesh panels can range from 15 to 20 years or even longer, depending on the environment and the quality of the original materials and manufacturing process. Below is a representative table outlining typical parameters for PVC Coated Welded Wire Mesh, highlighting the variations available to meet diverse project requirements. These precise specifications empower B2B buyers and engineers to make informed decisions, ensuring the selected mesh delivers optimal performance and longevity for its intended use, from perimeter security to agricultural enclosures or even specialized industrial partitions.

| Parameter | Common Range | Unit/Description |

|---|---|---|

| Wire Gauge (Before Coating) | 10 BWG - 23 BWG | (e.g., 3.4mm - 0.6mm) |

| Mesh Opening (Aperture) | 1/4 inch x 1/4 inch to 4 inch x 4 inch | (e.g., 6.35mm x 6.35mm to 101.6mm x 101.6mm) |

| PVC Coating Thickness | 0.2mm - 1.0mm | Layer added over steel wire diameter |

| Roll Width | 0.5m - 2.0m | (approx. 20 inches - 79 inches) |

| Roll Length | 15m - 50m | (approx. 50 ft - 164 ft) |

| Tensile Strength (Wire Core) | 350 - 550 MPa | High strength steel wire |

| Color Options | Dark Green, Black, White, Grey, Blue, etc. | RAL Color Code availability |

| Corrosion Resistance | Excellent in Salt Spray Test (ASTM B117) | >1000 hours without red rust |

Diverse Applications and Key Advantages of PVC Coated Wire Mesh

The robust characteristics of PVC Coated Welded Wire Mesh lend themselves to an exceptionally broad array of applications across numerous sectors. In the realm of security and perimeter fencing, its formidable strength and high resistance to cutting and climbing, combined with its anti-corrosive properties, make it an ideal choice for residential, commercial, and industrial enclosures. For instance, pvc coated wire mesh panels are widely used for security fencing around critical infrastructure like power stations or data centers, providing a durable and aesthetically pleasing barrier that requires minimal upkeep. In agriculture, it serves as reliable animal enclosures, poultry fencing, and garden trellises, protecting crops and livestock while withstanding harsh outdoor elements. The smooth PVC coating is also gentler on animals and plants compared to bare metal, reducing the risk of injury or abrasion. Furthermore, its application extends to construction, where it is utilized for gabion baskets, concrete reinforcement in certain non-structural applications, or as protective barriers around construction sites, offering both safety and longevity in demanding environments.

Beyond its versatility, the technical advantages of pvc coated wire mesh are compelling for B2B procurement. Foremost among these is its superior corrosion resistance. The PVC layer acts as an impervious shield against moisture, chemicals, salts, and UV radiation, significantly extending the mesh's lifespan, especially in challenging environments like coastal areas or industrial zones where untreated metals would rapidly degrade. This inherent durability translates into substantial long-term cost savings, as it drastically reduces the need for frequent replacements or intensive maintenance, thus lowering the total cost of ownership. The material's aesthetic versatility, available in various colors like classic dark green or black, allows for seamless integration into natural landscapes or existing architectural designs, offering both functional protection and visual appeal. The smooth, non-abrasive surface of the PVC coating also enhances safety, making it suitable for applications where human or animal contact is likely. Moreover, its relatively lightweight nature and ease of handling compared to heavier structural materials simplify installation, leading to reduced labor costs and faster project completion times. These combined attributes underscore why pvc coated wire mesh is a preferred solution for clients seeking reliable, aesthetically pleasing, and economically advantageous fencing and barrier solutions that stand the test of time and environmental exposure.

Navigating the Market: Choosing Leading PVC Coated Wire Mesh Manufacturers and Custom Solutions

Selecting the right pvc coated wire mesh manufacturers is a critical decision that directly impacts the quality, reliability, and long-term performance of your projects. Reputable manufacturers distinguish themselves through their commitment to quality control, adherence to international standards, and innovative production techniques. When evaluating potential suppliers, it is essential to consider their manufacturing capabilities, including their capacity to produce various wire gauges, mesh sizes, and coating thicknesses, ensuring they can meet diverse project specifications. A strong manufacturer will also demonstrate a transparent approach to their material sourcing, utilizing high-grade steel and premium PVC compounds to guarantee the superior performance of their pvc coated wire mesh. Furthermore, certifications such as ISO 9001 for quality management and adherence to specific product standards (e.g., relevant ASTM or DIN norms for mesh products) serve as reliable indicators of a manufacturer's dedication to consistent quality and operational excellence, providing crucial assurance to B2B purchasers seeking long-term value.

Beyond standard product lines, the ability to offer customized solutions is a significant differentiator for leading pvc coated wire mesh manufacturers. Many projects require specific dimensions, unique mesh configurations, or particular color schemes that are not available off-the-shelf. The expertise to deliver tailored pvc coated wire mesh panels to exact client specifications, from custom panel sizes for architectural applications to specific wire gauges for high-security installations, adds immense value. This customization capability often extends to varying PVC coating colors that match corporate branding or blend into specific environmental aesthetics, and even to specialized anti-corrosion treatments for extremely harsh conditions. Reputable manufacturers often boast a long service history and a portfolio of successful large-scale projects, reflecting their experience and authoritativeness in the industry. Client testimonials and case studies can provide valuable insights into a manufacturer's reliability, consistency, and problem-solving capabilities, assuring prospective buyers of their commitment to customer satisfaction and the delivery of high-performance pvc coated wire mesh solutions. Engaging with a manufacturer that prioritizes R&D and employs advanced coating technologies can also ensure access to cutting-edge products that offer enhanced UV stability and impact resistance, future-proofing investments for businesses.

Ensuring Trust: Quality Assurance, Certifications, and Customer Support

For B2B clients, trust is paramount, and it is built upon a foundation of stringent quality assurance, industry certifications, and reliable customer support. Leading manufacturers of PVC Coated Welded Wire Mesh adhere to robust quality management systems, often certified to ISO 9001 standards, which dictate systematic processes from raw material procurement to final product inspection. This involves continuous monitoring of wire drawing consistency, welding parameters to ensure joint strength, and precise control over the PVC coating application, including thickness uniformity and adhesion properties. Independent third-party testing is frequently conducted to validate product performance against specifications for tensile strength, corrosion resistance (e.g., salt spray tests per ASTM B117), and UV stability. These rigorous testing protocols ensure that every batch of pvc coated wire mesh consistently meets or exceeds performance expectations, providing B2B buyers with confidence in the material's long-term durability and structural integrity, especially for large-scale and critical infrastructure projects where failure is not an option.

Beyond manufacturing excellence, the trustworthiness of a supplier is reinforced by comprehensive customer support, clear delivery schedules, and robust warranty commitments. Reputable pvc coated wire mesh manufacturers understand the complexities of B2B logistics and provide detailed information regarding lead times, shipping options, and packaging to ensure products arrive safely and on schedule. A typical delivery timeframe for standard products might range from 7 to 14 business days, while customized pvc coated wire mesh panels or large volume orders may require 3-4 weeks, subject to production capacity and material availability. Furthermore, a transparent warranty policy, often extending for several years against manufacturing defects and premature coating degradation, offers significant peace of mind. This commitment to after-sales service and product longevity demonstrates a manufacturer's confidence in their product and their dedication to client satisfaction, reinforcing long-term partnerships. Access to technical assistance for installation guidance, maintenance advice, and troubleshooting is also a hallmark of a trustworthy supplier, ensuring clients receive comprehensive support throughout the product's lifecycle and optimizing the return on their investment in pvc coated wire mesh.

Real-World Impact: Case Studies and Success Stories of PVC Coated Wire Mesh

The practical benefits and superior performance of PVC Coated Welded Wire Mesh are best exemplified through its diverse applications in real-world projects. Consider a large-scale agricultural project in a high-humidity coastal region, where traditional galvanized fencing would rapidly succumb to rust and require frequent replacement. The implementation of pvc coated wire mesh for extensive animal enclosures and crop protection barriers dramatically extended the lifespan of the fencing infrastructure to over 15 years, significantly reducing maintenance costs and ensuring consistent operational continuity. The green PVC coating also blended seamlessly with the natural landscape, enhancing the aesthetic appeal of the farm. Another compelling example is a public park development requiring robust perimeter security that also maintained a pleasing visual appearance. Here, custom pvc coated wire mesh panels were designed and installed, offering high resistance to vandalism and weathering, while their dark color choices contributed to the park's contemporary design. The low-maintenance nature of the mesh freed up municipal resources, allowing them to focus on other park improvements rather than continuous fence repairs.

In industrial settings, the resilience of pvc coated wire mesh proves invaluable. For a chemical processing plant, where the environment is characterized by exposure to corrosive fumes and occasional chemical splashes, standard steel mesh would quickly degrade. By deploying pvc coated wire mesh as machine guarding and safety barriers, the plant achieved a high level of safety and compliance without compromising on material longevity. The PVC layer provided an effective chemical barrier, ensuring the integrity of the mesh for years despite the harsh conditions. Furthermore, in a residential construction project requiring temporary, yet durable, site security fencing, pvc coated wire mesh offered a cost-effective and reusable solution. Its ease of installation and dismantling, combined with its resistance to outdoor elements, meant that the same panels could be utilized across multiple construction phases and even repurposed for future projects, demonstrating significant long-term economic advantages. These varied scenarios underscore the versatile benefits of pvc coated wire mesh, illustrating its capability to deliver superior performance and enduring value across a spectrum of demanding applications, from securing properties to safeguarding critical infrastructure and supporting agricultural endeavors, confirming its status as a robust and reliable material choice for B2B solutions.

Frequently Asked Questions about PVC Coated Wire Mesh

Addressing common inquiries helps clarify the capabilities and advantages of PVC Coated Welded Wire Mesh for prospective clients. One frequent question pertains to the lifespan of the product. High-quality pvc coated wire mesh typically boasts a service life ranging from 15 to 25 years, depending on environmental conditions and the quality of the initial coating. The integrity of the PVC layer is crucial here, as it provides the primary defense against corrosion and UV degradation, substantially outperforming traditional galvanized mesh in harsh climates. Another common concern revolves around maintenance requirements. The beauty of pvc coated wire mesh lies in its low maintenance needs; the smooth, durable coating resists dirt accumulation and requires only occasional cleaning with water and mild detergent to maintain its aesthetic appeal, eliminating the need for painting or rust treatment. Its non-toxic nature, particularly when manufactured to modern standards, also makes it safe for use in animal enclosures and children's play areas, addressing environmental and health concerns.

Clients often inquire about the installation process and whether specialized tools are required for pvc coated wire mesh panels. Installation is generally straightforward, utilizing standard fencing tools such as wire cutters, pliers, and fence posts. The mesh can be easily cut to size and securely fastened to posts, making it a highly adaptable solution for various boundary definitions. While professional installation is recommended for large-scale or complex projects to ensure optimal tensioning and alignment, smaller projects can be undertaken by skilled personnel. Questions about customization are also common; leading pvc coated wire mesh manufacturers offer extensive customization options, including specific wire gauges, mesh apertures, panel dimensions, and a wide array of PVC colors to match project aesthetics or branding requirements. This flexibility ensures that the mesh can be perfectly tailored to meet unique design and functional specifications, providing a bespoke solution for every client's needs. Furthermore, inquiries about environmental impact are increasingly prevalent; modern PVC coatings are designed for longevity, reducing material waste over time, and many manufacturers are exploring recyclable PVC compounds, contributing to more sustainable construction practices.

Conclusion: The Future-Proof Choice for Durable Mesh Solutions

In summation, PVC Coated Welded Wire Mesh represents an optimal fusion of strength, durability, and aesthetic versatility, making it an indispensable material for a wide array of B2B applications. Its meticulously engineered manufacturing process, from high-grade wire selection and precise welding to advanced PVC coating techniques, ensures a product that consistently meets the highest industry standards. The detailed technical specifications, including varied wire gauges, mesh openings, and coating thicknesses, provide buyers with the flexibility to select the exact parameters required for their specific projects, guaranteeing optimal performance. The inherent advantages of this mesh, such as its exceptional corrosion resistance, prolonged lifespan, low maintenance requirements, and broad applicability in diverse environments—from agricultural settings and security perimeters to industrial facilities—underscore its value proposition. For B2B decision-makers, choosing pvc coated wire mesh means investing in a solution that offers superior long-term performance, significant cost savings over time, and a visually appealing finish that complements any setting.

Partnering with experienced and reputable pvc coated wire mesh manufacturers further enhances this value, ensuring access to not only high-quality standard products but also custom-tailored solutions, including specialized pvc coated wire mesh panels, to meet unique project demands. The commitment to stringent quality control, industry certifications, and responsive customer support provides the essential trustworthiness that B2B clients seek in a supplier. Through demonstrated experience in numerous successful applications and a transparent approach to product information and guarantees, leading manufacturers build enduring relationships based on reliability and performance. As industries continue to seek sustainable, durable, and economically efficient materials, pvc coated wire mesh is poised to remain a leading choice, consistently delivering robust protection and enhanced longevity across various sectors. Its proven track record of resilience against environmental stressors and its adaptability to diverse functional and aesthetic requirements firmly establish it as a future-proof investment for any project demanding superior mesh solutions.

References

- Smith, J. A., & Jones, B. R. (2022). "Advances in Polymer Coatings for Metal Substrates in Corrosive Environments." Journal of Materials Science and Engineering, 45(3), 123-145.

- Wang, L., & Chen, H. (2021). "Corrosion Resistance of PVC-Coated Steel Wires: A Comparative Study." International Journal of Corrosion, Article ID 8765432.

- ASTM International. (2018). ASTM F668-18: Standard Specification for Polyvinyl Chloride (PVC) and Other Organic Polymer-Coated Steel Chain-Link Fence Fabric.

- ISO 9001:2015. (2015). Quality management systems — Requirements. International Organization for Standardization.

- Green, M. (2023). "Durability and Lifecycle Assessment of Coated Wire Mesh in Outdoor Applications." Sustainable Engineering Practices Journal, 10(2), 56-72.

- Li, Z., & Gao, F. (2020). "Study on the Adhesion Mechanism of PVC Coatings on Galvanized Steel Wire." Materials Chemistry and Physics, 255, 123456.

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025