Aug . 13, 2024 10:59 Back to list

Welded Metal Mesh

Welded Metal Mesh

Introduction

This article will give detailed information about welded wire mesh.

The article will give details on topics regarding:

- What is a welded wire mesh?

- Types of welded wire mesh

- Benefits and applications of using welded wire mesh

- Galvanized wire mesh manufacturing methods

- Galvanized steel mesh panel

- Types of galvanized steel mesh panels

- Applications and benefits of galvanized steel mesh panels

- And much more...

Chapter 1: What is Welded Wire Mesh?

Welded wire mesh consists of a series of wires welded together at the points where they intersect. The size of the mesh openings can vary based on the type of wire used and the intended function of the mesh. Regardless of the size or type of wire, welded wire mesh is extremely durable and cannot be deconstructed without the application of significant force.

The manufacturing process of welded wire mesh involves threading spools of wire through a welding machine. This machine is programmed to weld the numerous intersections of the wires uniformly, efficiently, and quickly, allowing for simultaneous welding at multiple points.

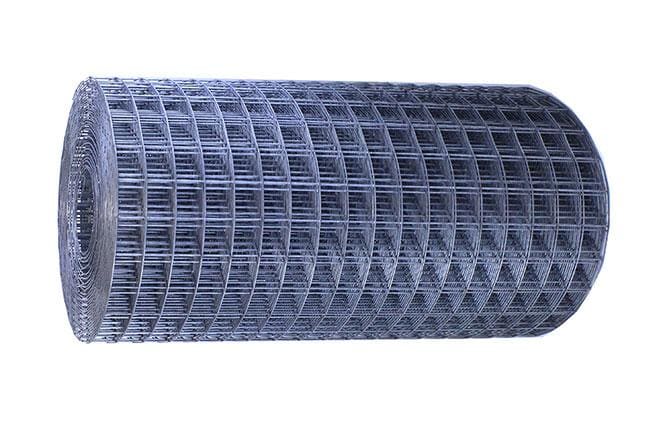

Welded wire mesh, also known as "weldmesh," is available in rolls or sheets. Thinner wires can be used to create larger open areas while still maintaining the mesh's strength and stability. Welded wire mesh is typically made from mild steel, galvanized steel, or stainless steel.

In construction, mild steel is often used for retaining walls or reinforcing structures. Galvanized mild steel is commonly used for fences, security screens, partitions, general storage solutions, machine guards, cages, and aviaries. The galvanized mesh can be made using pre-galvanized wire or hot-dipped wire, with hot-dipping preferred for its ability to conceal welds and provide a more polished appearance.

Stainless steel welded mesh is preferred in food or pharmaceutical production, where high hygiene standards are essential, or where the product needs to resist environmental conditions without rusting quickly.

Unlike woven mesh, where the opening is the clear space between wires, the opening for welded mesh is typically measured from the center of one wire to the center of the next. Therefore, when purchasing welded wire mesh, it's important to provide detailed information, including the material, center-to-center measurement (or clear opening), wire diameter, the required width and length, and the number of sheets or rolls needed.

Chapter 2: What Are the Different Types of Welded Wire Mesh?

Welded wire mesh is widely used due to its durability, strength, and versatility, maintaining its shape and form across various applications. Common uses include fencing, cages, shelving, and grates. Each application requires a specific type of welded wire mesh designed to meet the particular conditions.

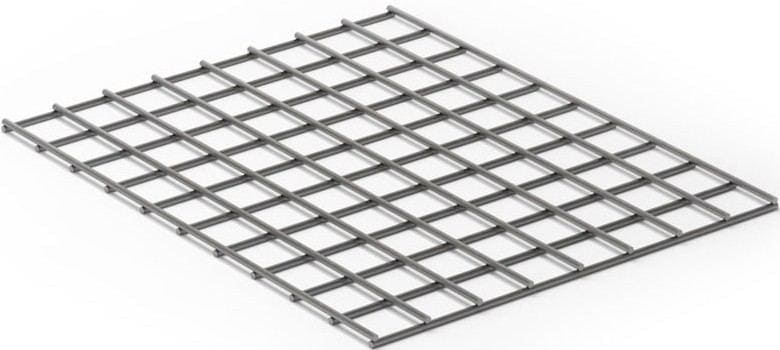

Welded wire mesh is also known as welded wire fabric. It is constructed and configured similarly, consisting of a prefabricated grid where longitudinal wires are precisely spaced and welded to cross wires. The intersections of these wires are automatically welded using electric resistance welding.

Square Welded Wire Mesh

Square welded wire mesh features intersecting wires that meet at right angles and are evenly spaced. This type of mesh is highly versatile and is commonly made from carbon steel or stainless steel.

Rectangular Welded Wire Mesh

Rectangular welded wire mesh is similar to square welded wire mesh, but with wires that intersect at right angles and are spaced further apart in one direction. This rectangular design enhances the mesh's strength.

Welded Mesh Sheet

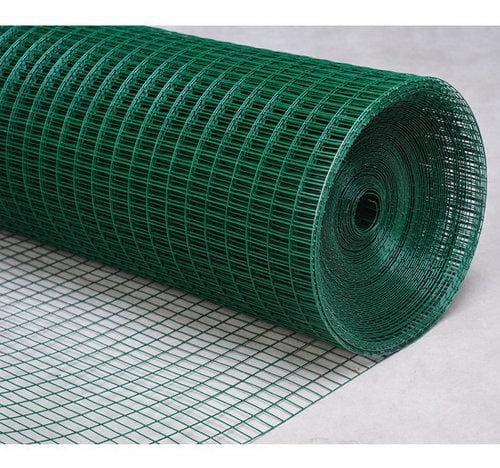

PVC Welded Wire Mesh

PVC welded wire mesh is coated with a thin layer of PVC powder to provide corrosion resistance, adding color and protecting the underlying metal. In addition to its resistance to corrosion, PVC welded wire mesh is also resistant to aging, sunlight, and weather. It is used across various industries, including farming, construction, transportation, and mining, to protect structures and workers, house livestock and poultry, and serve as a decorative element.

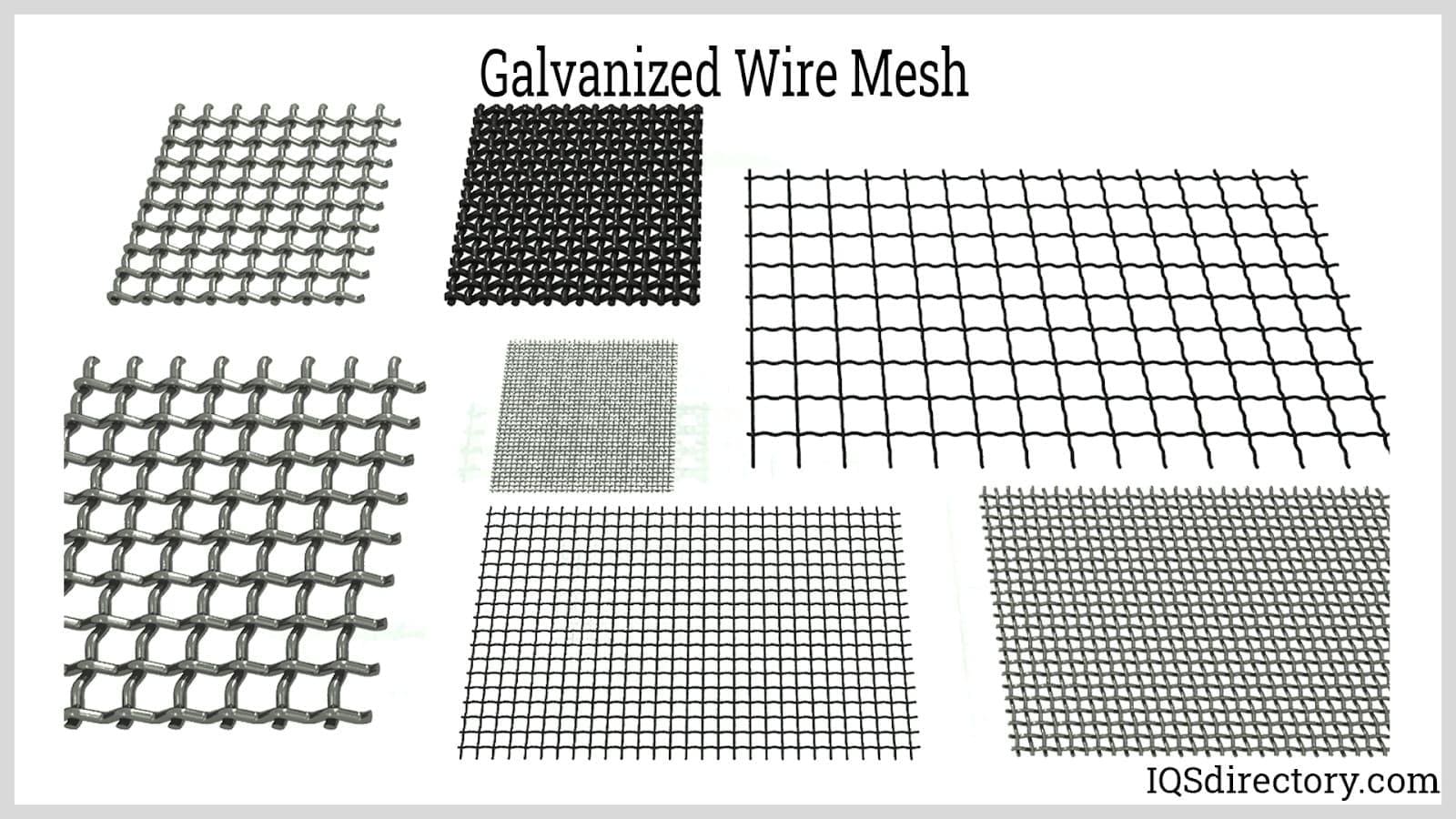

Galvanized Welded Wire Mesh

Galvanized welded wire mesh is coated with a protective layer of zinc to prevent rust and corrosion. This coating can be applied using either an electro-galvanizing process or hot dipping. Hot dipping involves immersing the welded wire mesh in molten zinc, which adheres to the wire's surface and provides a robust shield against rust. Electro-galvanizing, on the other hand, uses electricity to bond zinc to the metal wires. Galvanizing can be done either before or after the wire mesh is welded.

Galvanized wire mesh has different aperture sizes and wire diameters, which is one of its advantages. It is applied to welded wire mesh for a range of applications.

Welded Stainless Steel Wire Mesh

Welded stainless steel wire mesh is created by joining stainless steel wires at their intersections, forming a strong and uniform barrier. Known for its durability and strength, this type of wire mesh offers a consistent appearance and is one of the most popular choices available. The resistance welding process, which fuses the wires without the use of filler metal, results in a robust and reliable product. Welded stainless steel wire mesh can be cut into smaller shapes such as disks, squares, or rectangles. Due to its resistance to reacting with fluids, it is often used in filters and is extensively applied across various industries, including transportation, agriculture, mining, horticulture, and leisure.

Welded Wire Fencing

Welded wire fencing is available in rolls or panels and can be galvanized or non-galvanized, with non-galvanized options generally being more affordable. Installation is straightforward, particularly when replacing or adding to an existing deck. Custom rolls are made to order based on customer specifications, requiring minimal cutting and can be installed by one or two skilled individuals. Wire fence rolls are especially suited for large-scale projects that need extensive coverage and may involve work crews and expert installers.

To install welded wire fencing, you'll need posts, rings, pliers, and other essential tools. The panels are pre-fabricated in specific shapes and sizes, which allows for easy disassembly and reuse.

Welded wire fencing is made from thick gauge steel, which necessitates the use of torches for cutting, as conventional cutting methods are ineffective. Its robust steel construction, combined with posts set deep in the ground and secured with cement footings, makes welded wire fencing one of the most stable fencing options available. It is suitable for use in urban, suburban, rural, and industrial environments.

Heavy Welded Wire Mesh

Heavy welded wire mesh is distinguished by its significantly larger wire diameter compared to other types of welded wire mesh. Made from the same materials as traditional welded wire mesh but with thicker, more robust wires, it offers enhanced strength and durability. This makes heavy welded wire mesh suitable for use in floor reinforcement, wall structures, and various construction applications.

The properties and characteristics of heavy welded wire mesh depend on the materials used in its production. Stainless steel and galvanized heavy wire mesh, for instance, are both resistant to corrosion and capable of withstanding extreme conditions.

-

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025