Feb . 08, 2025 06:24 Back to list

welded wire fence

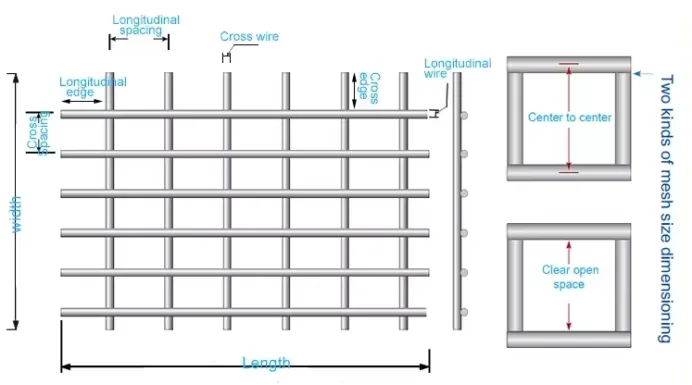

The demand for durable and cost-effective fencing solutions has made welded wire fences increasingly popular across various sectors such as agriculture, residential settings, and industrial environments. As someone deeply vested in this industry, understanding the nuances of selecting and maintaining a welded wire fence is essential to ensure that your investment in this fencing solution lasts for years to come.

Maintenance plays a critical role in sustaining a welded wire fence's effectiveness and extends its lifespan significantly. Regular inspections to spot any signs of wear and tear, such as rust spots or loose wires, are non-negotiable. Addressing these issues promptly by either re-fastening loose areas or applying anti-corrosion treatments where needed is crucial. Drawling on trustworthiness, for industrial applications such as those in chemical plants, adhering to a meticulous maintenance schedule is indispensable, given the potential exposure to harsh environmental factors. In the realm of versatility and application, welded wire fences stand out. They are adaptable to a wide range of uses, from keeping livestock secure in rural settings to safeguarding private property lines in urban environments. Moreover, they serve as an excellent base for installing other security measures, such as barbed wires or electric fencing systems, for areas that demand heightened security. Bringing it all together, welded wire fences represent a synthesis of practical utility, robust design, and aesthetic flexibility. It's this combination that makes them an investment worth considering for anyone needing to secure their land or property effectively. Based on extensive field research and implementation across varied scenarios, welded wire fences balance cost, durability, and performance in a way that few other fencing options can claim. Choosing the right type of welded wire fence should involve a precise assessment of the specific environmental conditions it will face, complemented by a rigorous installation and maintenance regime. By adhering to these principles and leveraging high-quality materials, property owners can expect their fenced perimeters to remain resilient and dependable over time.

Maintenance plays a critical role in sustaining a welded wire fence's effectiveness and extends its lifespan significantly. Regular inspections to spot any signs of wear and tear, such as rust spots or loose wires, are non-negotiable. Addressing these issues promptly by either re-fastening loose areas or applying anti-corrosion treatments where needed is crucial. Drawling on trustworthiness, for industrial applications such as those in chemical plants, adhering to a meticulous maintenance schedule is indispensable, given the potential exposure to harsh environmental factors. In the realm of versatility and application, welded wire fences stand out. They are adaptable to a wide range of uses, from keeping livestock secure in rural settings to safeguarding private property lines in urban environments. Moreover, they serve as an excellent base for installing other security measures, such as barbed wires or electric fencing systems, for areas that demand heightened security. Bringing it all together, welded wire fences represent a synthesis of practical utility, robust design, and aesthetic flexibility. It's this combination that makes them an investment worth considering for anyone needing to secure their land or property effectively. Based on extensive field research and implementation across varied scenarios, welded wire fences balance cost, durability, and performance in a way that few other fencing options can claim. Choosing the right type of welded wire fence should involve a precise assessment of the specific environmental conditions it will face, complemented by a rigorous installation and maintenance regime. By adhering to these principles and leveraging high-quality materials, property owners can expect their fenced perimeters to remain resilient and dependable over time.

Latest news

-

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025