Feb . 18, 2025 01:27 Back to list

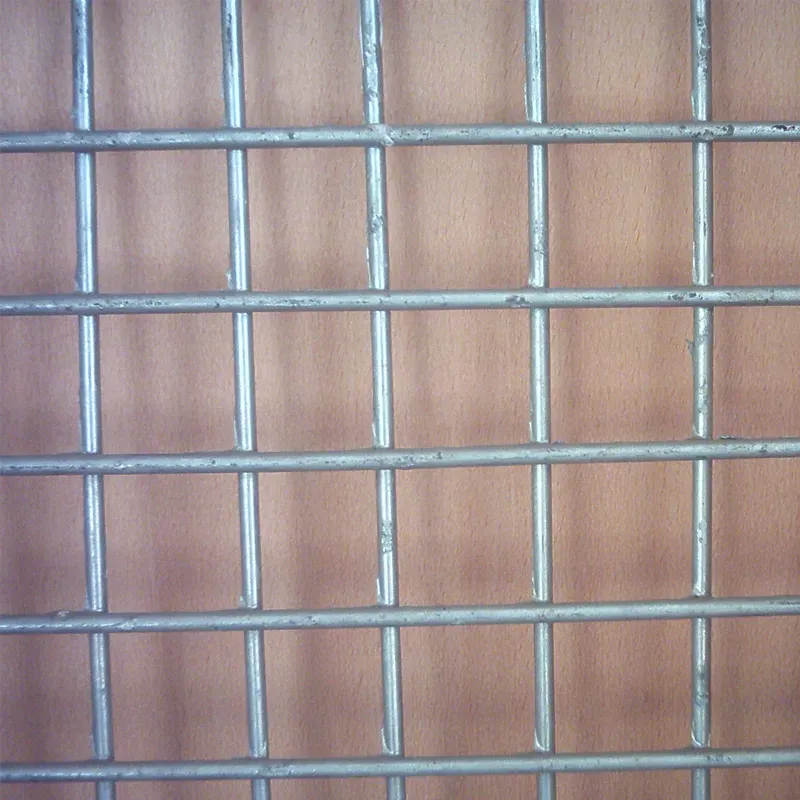

Galvanized Welded Wire Mesh

The welded mesh galvanised wire panel stands as a paramount player in the construction industry, renowned for its robustness, flexibility, and long-lasting qualities. This sophisticated mesh product, created from wire that has been spot welded at each intersection, is further enhanced through galvanisation, which involves coating the wire with a protective layer of zinc. This double-layered protective and connective method ensures that these panels not only resist rust and environmental damage but also offer a sturdy and dependable solution for various applications.

In terms of trustworthiness, welded mesh galvanised wire panels have been put to the test over decades of application in diverse conditions. Case studies from infrastructure projects worldwide showcase their performance in extreme climates, from the hot, saline air of coastal regions to the bitter chill of high-altitude locations. These practical validations affirm users' confidence in relying on the panels for both functional and safety concerns. When incorporating welded mesh galvanised wire panels into a project, it is essential to consider the installation process, which requires proficiency and keen attention to quality. Although the installation is relatively straightforward compared to other construction materials, precise measurements and securing techniques ensure that the panels perform optimally. Engaging with experienced professionals who are well-versed in these panels can prevent mishaps and guarantee the success of the construction endeavor. In conclusion, welded mesh galvanised wire panels are a model of modern engineering that stands the test of time through continuous innovation and proven performance. Their widespread use in diverse industry sectors underscores their versatility and reliability, making them a preferred choice for sustainable building practices across the globe. Architects, engineers, and builders continue to trust and invest in these panels, drawn by their enduring characteristics that balance strength, economy, and adaptability. Whether for security, aesthetics, or structural support, welded mesh galvanised wire panels remain a cornerstone of effective and efficient construction practices.

In terms of trustworthiness, welded mesh galvanised wire panels have been put to the test over decades of application in diverse conditions. Case studies from infrastructure projects worldwide showcase their performance in extreme climates, from the hot, saline air of coastal regions to the bitter chill of high-altitude locations. These practical validations affirm users' confidence in relying on the panels for both functional and safety concerns. When incorporating welded mesh galvanised wire panels into a project, it is essential to consider the installation process, which requires proficiency and keen attention to quality. Although the installation is relatively straightforward compared to other construction materials, precise measurements and securing techniques ensure that the panels perform optimally. Engaging with experienced professionals who are well-versed in these panels can prevent mishaps and guarantee the success of the construction endeavor. In conclusion, welded mesh galvanised wire panels are a model of modern engineering that stands the test of time through continuous innovation and proven performance. Their widespread use in diverse industry sectors underscores their versatility and reliability, making them a preferred choice for sustainable building practices across the globe. Architects, engineers, and builders continue to trust and invest in these panels, drawn by their enduring characteristics that balance strength, economy, and adaptability. Whether for security, aesthetics, or structural support, welded mesh galvanised wire panels remain a cornerstone of effective and efficient construction practices.

Latest news

-

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025