Feb . 10, 2025 09:56 Back to list

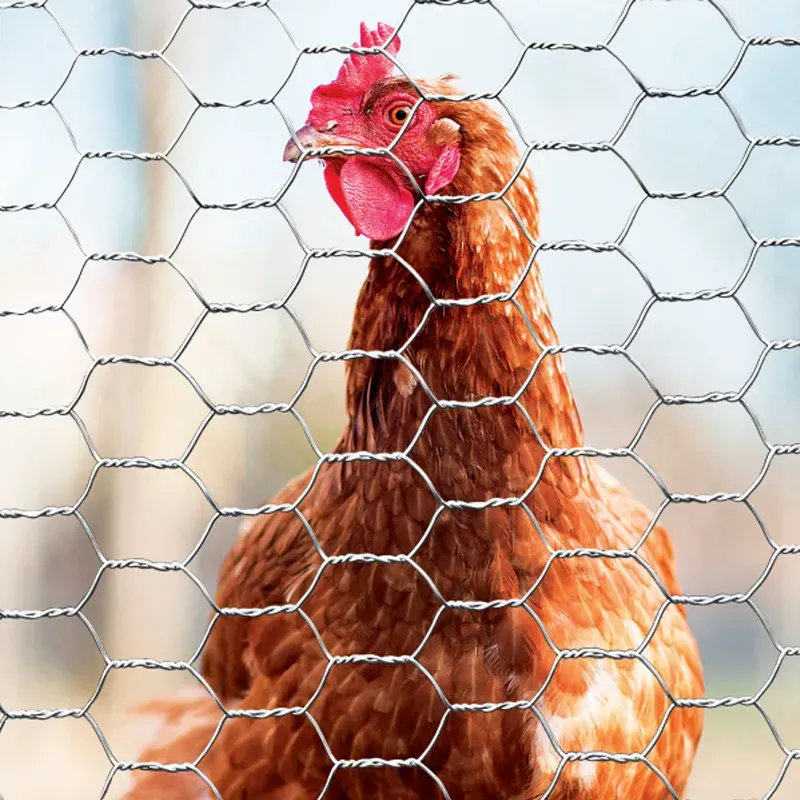

welded mesh galvanised wire panel

Welded mesh galvanised wire panels have become an essential component in a multitude of construction and agricultural projects due to their resilience and durability. These panels are crafted from wires that are welded together to create a strong and uniform grid pattern, subsequently galvanized to enhance their resistance to corrosion. This tried-and-true manufacturing process bestows the panels with several intrinsic benefits, making them incredibly versatile in a range of applications.

When discussing authoritativeness, the adoption of welded mesh galvanised wire panels extends beyond just their physical attributes. These panels meet numerous international standards and certifications, attesting to their quality and safety. Structural engineers and architects often specify these panels in their projects, showing a trust rooted in proven engineering principles and historical usage in countless successful applications. The compliance with industry standards serves as a testament to their suitableness in high-stakes environments, further solidifying their reputable status. On the trustworthiness front, clients and stakeholders often base their product choice on proven track records and testimonials. Welded mesh galvanised wire panels boast a history of delivering exceptional results across various sectors. Feedback from users typically highlights the enduring performance and cost-effectiveness of these panels. By investing in such time-tested products, businesses and individuals alike can rest assured that they are utilizing materials that have been rigorously tested and validated by industry professionals. In conclusion, welded mesh galvanised wire panels represent a confluence of robust engineering, expert manufacturing, and unwavering reliability. Whether employed in construction for reinforcing concrete or serving as protective barriers in agricultural settings, these panels provide a dependable solution that aligns with the high standards expected in both industries. With their combination of strength, durability, and resistance to environmental factors, they continue to be a product of choice for those seeking to blend quality with longevity.

When discussing authoritativeness, the adoption of welded mesh galvanised wire panels extends beyond just their physical attributes. These panels meet numerous international standards and certifications, attesting to their quality and safety. Structural engineers and architects often specify these panels in their projects, showing a trust rooted in proven engineering principles and historical usage in countless successful applications. The compliance with industry standards serves as a testament to their suitableness in high-stakes environments, further solidifying their reputable status. On the trustworthiness front, clients and stakeholders often base their product choice on proven track records and testimonials. Welded mesh galvanised wire panels boast a history of delivering exceptional results across various sectors. Feedback from users typically highlights the enduring performance and cost-effectiveness of these panels. By investing in such time-tested products, businesses and individuals alike can rest assured that they are utilizing materials that have been rigorously tested and validated by industry professionals. In conclusion, welded mesh galvanised wire panels represent a confluence of robust engineering, expert manufacturing, and unwavering reliability. Whether employed in construction for reinforcing concrete or serving as protective barriers in agricultural settings, these panels provide a dependable solution that aligns with the high standards expected in both industries. With their combination of strength, durability, and resistance to environmental factors, they continue to be a product of choice for those seeking to blend quality with longevity.

Latest news

-

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025