Dec . 14, 2024 10:04 Back to list

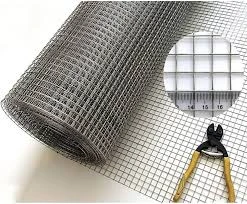

Galvanized Wire Mesh Panels for Durable and Reliable Welded Fencing Solutions

The Benefits and Applications of Welded Mesh Galvanized Wire Panels

Welded mesh galvanized wire panels are essential materials in various industries, given their versatility, strength, and durability. These panels are made from high-quality steel wire that has been welded together at intersections, then coated with a layer of zinc to provide excellent resistance to corrosion. This article explores the benefits, applications, and considerations of using galvanized welded mesh panels in various settings.

Benefits of Welded Mesh Galvanized Wire Panels

1. Durability and Longevity One of the primary advantages of galvanized wire panels is their durability. The zinc coating protects the underlying steel from rust and corrosion, enabling the panels to withstand harsh weather conditions and environments. This longevity reduces the need for frequent replacements, making them a cost-effective option for long-term use.

2. Versatility Welded mesh panels are highly versatile. They come in various sizes, wire diameters, and mesh configurations, which makes them suitable for multiple applications, including fencing, animal enclosures, security barriers, and construction scaffolding. Their adaptability means they can be tailored to meet specific project needs.

3. Structural Integrity The welded construction provides superior structural integrity compared to other types of fencing or mesh solutions. This strength not only provides enhanced security but also allows the panels to support significant weight, making them ideal for uses in construction and heavy-duty applications.

4. Easy Installation Unlike traditional fencing or barrier systems, which often require extensive groundwork or complex installation processes, galvanized welded mesh panels are relatively easy to install. They can be quickly secured in place using various methods, including concrete, post mounting, or chain-link systems, which helps save time and labor costs on projects.

5. Low Maintenance Once installed, welded mesh galvanized wire panels require minimal maintenance. The protective zinc coating prevents rust and corrosion, cleaning them with water or mild detergent is typically all that is needed to keep them looking new and functional.

Applications of Welded Mesh Galvanized Wire Panels

welded mesh galvanised wire panel

1. Fencing One of the most common applications of galvanized welded mesh panels is in fencing. They provide a secure enclosure for residential properties, commercial premises, and agricultural fields. The visibility through the mesh allows for monitoring while maintaining security.

2. Construction and Scaffolding In the construction industry, these panels are widely used for scaffolding systems. Their strength and stability ensure a safe working environment. They can also be integrated into temporary barriers during construction projects to safeguard the work site.

3. Agricultural Use Galvanized welded mesh panels find extensive use in agriculture for building livestock enclosures, poultry houses, and crop protection. The panels provide a secure environment for animals while allowing for airflow and visibility.

4. Industrial Applications Industries often utilize welded mesh panels for safety fences, machine guards, and storage enclosures. Their robustness makes them ideal for protecting equipment and ensuring workplace safety.

5. Landscaping and Decorative Uses Beyond practical applications, galvanized welded mesh can also be employed in landscaping for decorative fences, trellises, and garden supports. They offer a modern aesthetic while providing functionality.

Considerations When Choosing Welded Mesh Galvanized Wire Panels

While galvanized welded mesh panels offer numerous benefits, there are certain considerations to keep in mind. It is crucial to assess the specific requirements of your project, including load-bearing capacity, mesh size, and environmental conditions. Additionally, ensuring that panels are sourced from reputable manufacturers guarantees quality and reliability.

Conclusion

Welded mesh galvanized wire panels are invaluable in many settings due to their durability, versatility, and low maintenance requirements. Their applications span various industries, making them a popular choice for fencing, construction, agriculture, and industrial purposes. By considering the specific needs of your project, you can leverage the many advantages these panels provide, ensuring long-lasting effectiveness and efficiency.

-

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025