Nov . 13, 2024 15:12 Back to list

soft iron wire

The Versatile Applications of Soft Iron Wire

Soft iron wire, a remarkable material employed in various industries, exhibits a unique combination of properties that make it invaluable in diverse applications. Characterized by its high ductility and low carbon content, soft iron wire is malleable and easily shaped, allowing for its extensive use in both engineering and craft projects. This article explores the properties, production processes, and applications of soft iron wire, highlighting its significance in modern technology and everyday life.

Properties of Soft Iron Wire

Soft iron is predominantly composed of iron with only a minimal amount of carbon, typically less than 0.1%. This low carbon content contributes to its soft and ductile nature, making it capable of being drawn into fine wires without breaking. Additionally, soft iron exhibits excellent magnetic properties, including high permeability and low retentivity. This means that it can easily become magnetized when exposed to a magnetic field but loses its magnetism almost entirely when the field is removed.

The ability to conduct electricity efficiently, while also being weakly magnetic, positions soft iron wire as a critical component in many electrical applications. Its resilience and flexibility make it suitable for use in applications that require bending and coiling, ensuring that it can maintain functionality under various conditions.

Production of Soft Iron Wire

The production of soft iron wire involves several steps, starting with the extraction of iron from its ores. The iron is then refined to reduce its carbon content, often through a process known as smelting. During smelting, the iron is heated in a furnace, and impurities are removed, leading to a purer form of iron that can be further processed.

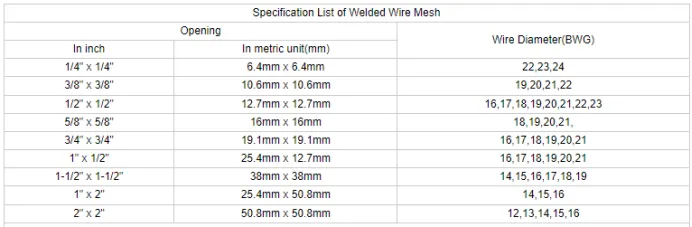

Once the soft iron is produced, it can be drawn into wire through a method called wire drawing. This process involves pulling the iron through progressively smaller dies, which shape it into finer diameters. The final product can vary significantly in thickness, ranging from thick gauge wire used for structural applications to extremely fine wire utilized in delicate crafts and electrical components.

soft iron wire

Applications of Soft Iron Wire

The versatility of soft iron wire leads to its use in a myriad of applications across different sectors. One of the primary applications is in the manufacturing of electrical transformers and inductors. Due to its excellent magnetic properties, soft iron wire is often used in the construction of magnet cores, which enhance the efficiency of electromagnetic devices.

In the automotive industry, soft iron wire is commonly utilized in various components, including the manufacturing of springs, clips, and other fastening items that require flexibility and strength. The low carbon content ensures that these components can withstand stress and strain during operation without deforming.

Additionally, soft iron wire is popular in crafting and jewelry making. Artisans use it to create intricate designs, sculptures, and decorative items due to its malleability. The wire can be easily bent, twisted, or wrapped, allowing for creative freedom in artistic expression. Jewelry designers often prefer soft iron wire for its ability to be oxidized or coated, enabling them to achieve different finishes and colors.

In the field of construction, soft iron wire is utilized in the fabrication of wire mesh and reinforcement bars (rebars). This is essential for improving the tensile strength of concrete structures, ensuring stability and longevity. The wire’s ability to bond with concrete makes it a critical component in modern architecture.

Conclusion

Soft iron wire's unique properties and versatility make it an essential material in various domains. From its applications in electrical devices and automotive components to its artistic uses in jewelry making, the presence of soft iron wire is ubiquitous. Its ease of manipulation and excellent mechanical characteristics continue to inspire innovation across numerous fields. As technology advances, the demand for high-quality soft iron wire is likely to grow, promising a bright future for this remarkable material.

-

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025