Mar . 06, 2025 11:26 Back to list

roof sheathing nails

Roof sheathing nails might not seem like a topic worthy of deep exploration, yet these small, seemingly insignificant components play a pivotal role in the structural integrity and longevity of a building's roof. Knowledge of their application can profoundly impact roofing project's outcomes.

Authoritativeness comes into play through adherence to building codes and industry standards, such as those from the International Building Code (IBC). Codes ensure that nails provide sufficient withdrawal strength to prevent uplift from wind loads. Most codes specify that sheathing panels be nailed every 6 inches along edges and 12 inches along intermediate supports for optimal stability. Roofs in high-wind regions, like coastal areas, might require nails every 4 inches along the edges, underlining the need for professional expertise in code compliance. Trustworthiness is developed through consistent delivery of quality work. Using subpar materials or incorrect installation methods can lead to roof failures, damaging trust. Transparency with clients about product choices, installation techniques, and the benefits of specific nails fosters a long-term relationship based on reliability and quality. Professionally, integrating advanced technologies, such as pneumatic nail guns, improves precision and reduces labor times significantly. However, expertise is essential when adjusting these tools to drive nails consistently without damaging the roof substrate. Additionally, new technologies in nails, like ring shank nails, offer superior holding power over traditional smooth shank nails due to their design, proving beneficial in storm-prone areas. Sustainability considerations also deserve attention. As construction increasingly moves towards eco-friendly practices, selecting nails from manufacturers committed to sustainable sourcing of materials can be a discernible advantage. This choice not only supports environmentally friendly practices but also appeals to a growing demographic of environmentally conscious consumers. In conclusion, while roof sheathing nails may appear to be a minor aspect of roofing projects, the ripple effects of proper or improper nail selection extend to overall roof performance and longevity. The informed selection and application of these essential components ensure not just structural integrity, but customer satisfaction and business reputation. The choice of the right nails is a testament to a craftsman’s experience, expertise in the trade, adherence to authoritative guidelines, and unwavering trustworthiness. It's this detailed understanding and care in product selection and application that prepare us to support enduring, resilient roofing solutions, setting a benchmark for excellence and reliability in the construction industry.

Authoritativeness comes into play through adherence to building codes and industry standards, such as those from the International Building Code (IBC). Codes ensure that nails provide sufficient withdrawal strength to prevent uplift from wind loads. Most codes specify that sheathing panels be nailed every 6 inches along edges and 12 inches along intermediate supports for optimal stability. Roofs in high-wind regions, like coastal areas, might require nails every 4 inches along the edges, underlining the need for professional expertise in code compliance. Trustworthiness is developed through consistent delivery of quality work. Using subpar materials or incorrect installation methods can lead to roof failures, damaging trust. Transparency with clients about product choices, installation techniques, and the benefits of specific nails fosters a long-term relationship based on reliability and quality. Professionally, integrating advanced technologies, such as pneumatic nail guns, improves precision and reduces labor times significantly. However, expertise is essential when adjusting these tools to drive nails consistently without damaging the roof substrate. Additionally, new technologies in nails, like ring shank nails, offer superior holding power over traditional smooth shank nails due to their design, proving beneficial in storm-prone areas. Sustainability considerations also deserve attention. As construction increasingly moves towards eco-friendly practices, selecting nails from manufacturers committed to sustainable sourcing of materials can be a discernible advantage. This choice not only supports environmentally friendly practices but also appeals to a growing demographic of environmentally conscious consumers. In conclusion, while roof sheathing nails may appear to be a minor aspect of roofing projects, the ripple effects of proper or improper nail selection extend to overall roof performance and longevity. The informed selection and application of these essential components ensure not just structural integrity, but customer satisfaction and business reputation. The choice of the right nails is a testament to a craftsman’s experience, expertise in the trade, adherence to authoritative guidelines, and unwavering trustworthiness. It's this detailed understanding and care in product selection and application that prepare us to support enduring, resilient roofing solutions, setting a benchmark for excellence and reliability in the construction industry.

Latest news

-

Weather Resistance Properties of Quality Roofing Nails

NewsAug.01,2025

-

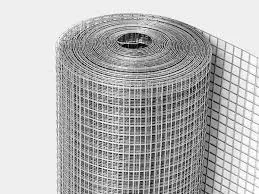

How Galvanised Iron Mesh Resists Corrosion in Harsh Environments

NewsAug.01,2025

-

Creative Landscaping Uses for PVC Coated Wire Mesh Panels

NewsAug.01,2025

-

Common Wire Nail Dimensions and Their Specific Applications

NewsAug.01,2025

-

Choosing the Right Welded Wire Sheets for Agricultural Fencing

NewsAug.01,2025

-

Anti - Climbing Features of Razor Wire Barriers

NewsAug.01,2025