Aug . 03, 2025 07:20 Back to list

Premium Bulk Roofing Nails: Durable & Affordable

In the rapidly evolving construction sector, reliability, cost efficiency, and durability are central considerations for building professionals and material buyers. Bulk roofing nails remain the mainstay for roof installations worldwide, driven by ongoing technical innovations and diversified application scenarios. This guide leverages the latest data, technical specifications, comparison charts, and real-world cases to help you make informed decisions on roofing fasteners – with a special focus on industry-leading Screw Roofing Nail solutions.

2024 Industry Trends: The Bulk Roofing Nails Market at a Glance

The global bulk roofing nails market was valued at USD 634 million in 2023 (Marketwatch), with projected CAGR at 4.3% through 2028. The demand is largely driven by infrastructure upgrades, increased investments in commercial roofing, and the rise of energy-efficient roof systems. Roofing nails for sale are increasingly sought for their advanced corrosion resistance and compatibility with automated nailing equipment.

- Top regions: North America, Southeast Asia, Western Europe

- Main applications: Residential roofing, commercial roofing, industrial sheds, modular buildings

- Certification standards: ISO 9001, ANSI/ASME B18.6.1, and EN 14592

Bulk Roofing Nails Technical Parameters (2024 Reference Table)

Technical parameters determine the cost of roofing nails, their longevity, and performance in harsh climates. Here's a snapshot comparing mainstream bulk roofing nails available in the market:

| Product Type | Material | Diameter (mm) | Length (mm) | Head Type | Surface Finish | Yield Strength (Mpa) | Corrosion Standard | Price (USD/ton, 2024) |

|---|---|---|---|---|---|---|---|---|

| Screw Roofing Nail | Q195/Q235 Carbon Steel, Stainless Steel | 2.0–4.2 | 20–120 | Umbrella, Flat | EG/Galvanized, PVC, HDG | 520–840 | ISO 9227, ASTM B117 | 695–1,200 |

| Standard Clout Nail | Q195 Steel | 2.4–4.1 | 25–100 | Umbrella | Electro-Galvanized | 410–560 | ISO 9227 | 630–1,075 |

| Coil Roofing Nail | Low Carbon Steel, SS201/304 | 2.5–3.3 | 25–100 | Round Flat | EG/HDG, Painted | 510–790 | ASTM B117 | 712–1,780 |

| Roofing Staples | Galvanized Wire | 1.1–1.6 | 23–32 | Flat | Galvanized | 620–700 | EN 10244 | 580–980 |

* Surface finish impacts corrosion resistance and project lifespan.

Manufacturing Process: From Steel Wire to Bulk Roofing Nails

Understanding the craftsmanship behind bulk roofing nails is vital for procurement and quality assurance. Here’s a concise overview of the manufacturing flow for a typical Screw Roofing Nail, emphasizing material selection, process control, and inspection stages.

Key Inspection Standards applied throughout include ISO 9001, ASTM B117 (corrosion), EN 10244, and ANSI B18.6.1 (geometry).

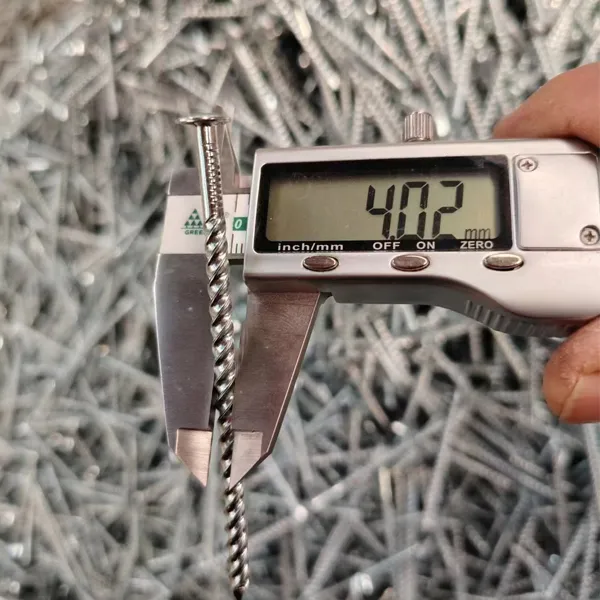

Screw Roofing Nail: Technical Data & Competitive Advantages

The Screw Roofing Nail is engineered with helical (screw) shank technology to maximize holding power in timber, OSB, or composite. Compared to standard smooth shank or ring shank alternatives, it offers superior withdrawal resistance and long-term roof membrane retention.

- **Material:** Steel (Q195/Q235), 201/304 SS, ISO/ANSI certified

- **Surface Coating:** Electro-galvanized, hot-dip galvanized (HDG), painted, PVC

- **Head Type:** Large umbrella, flat disc

- **Length:** 20–120mm; **Diameter:** 2.0–4.2mm

- **Tensile Strength:** ≥ 800MPa (hardened shank)

- **Tested Lift-Out Strength:** Up to 45% higher than ordinary clout nails (ANSI B18.6.1)

- **Corrosion Resistance:** 600–1440 hours salt spray test (ASTM B117)

- **Warranted Life:** ≥20 years (roofing conditions with correct installation)

With ISO 9001 and EN certification, Screw Roofing Nail is supplied to leading roofing contractors, prefab housing builders, and industrial project owners globally.

Bulk Roofing Nails vs Screw Roofing Nail: Data Visualization

Industry Application Scenarios: Bulk Roofing Nails in Action

Bulk roofing nails, including advanced screw shank models, are deployed across a broad spectrum of industries:

- Petrochemical plants: High-corrosion roofing systems, HDG and PVC-coated bulk roofing nails are a critical choice.

- Metallurgy workshops: Large-span roofs demand fasteners with high mechanical strength and anti-fatigue properties.

- Municipal and urban construction: Modular building and water supply & drainage shelters prefer bulk nails for rapid installation and maintenance.

- Prefabricated housing: Enhances deck/roof connection with screw roofing nails, supporting repeated expansion-contraction cycles.

- Agricultural & storage: Resistant to ammonium-based fertilizers, max corrosion-proofed for decades.

- Residential roofing: Shingles, slate, and tile roofs; umbrella-head design adds wind-lift protection.

Manufacturer Comparison: Leading Brands

Choosing the right bulk roofing nails supplier is crucial. Here’s a comparison of leading factories:

| Factory/Brand | Production Capacity (MT/year) | Main Certifications | Customization Support | Export Regions | Avg. Lead Time (Days) |

|---|---|---|---|---|---|

| YISZHE Screw Roofing Nail | 12,000 | ISO 9001, ASTM, CE, SGS | Full (head/shank/finish/packaging) | Global (80+ countries) | 10–18 |

| Jiangsu Fastener | 7,900 | ISO, EN | Partial | Asia, Europe | 14–22 |

| Huaqing Hardware | 8,200 | ISO, CE | Limited | Middle East, USA | 16–28 |

Customization Solutions for Bulk Roofing Nails

For projects with unique challenges—be it saltwater exposure, high wind uplift, or specific installation machines—bespoke bulk roofing nails are available. YISZHE provides:

- Custom head (umbrella/flat/cone) and shank (ring/smooth/spiral/screw) design

- Precise diameter/length matching installation equipment (from 2.0 to 4.2mm, up to 120mm)

- Specialized coatings (Zinc, HDG, Dacromet, epoxy, colored PVC) for max corrosion resistance

- Embossed and branding service for OEM clients

- Short-run prototyping & factory pre-shipment samples

Real-World Application Cases: Customer Feedback

Our stadium roof refurbishment project required superior withdrawal resistance. YISZHE’s Screw Roofing Nail (HDG) passed 96h salt spray and offered 41% higher holding vs standard ring shank nails. The install time was cut by 18%. — Engineering Lead, DKM Roofing

For a water treatment works, only 304SS roofing nails met the ISO corrosion criteria. YISZHE’s prompt custom delivery ensured our timelines, saving substantial rework costs. — Project Manager, Gulf EPC contractor

Switching from staple fasteners to screw roofing nails on modular barns reduced wind-related maintenance calls by 67%. Our end-users reported improved roof life and installation peace of mind. — Technical Director, Midwest Modular

Bulk roofing nails for sale from YISZHE delivered consistently high quality and cost transparency. The technical team provided solutions for improved fastener retraction in composite roofing. — Procurement Officer, AusBuild

FAQ: Professional Roofing Nail Terminology

Delivery Cycle, Warranty Policy & Customer Support

Bulk order 10–18 days (FOB China)

Expedited 3–7 days for standard stock.

2–5 year product warranty (EN/ISO, weather corrosion included)

Free defect exchange.

Traceable batch codes with each shipment.

24/7 fast response hotline.

Installation consultation, submittal support & OEM design review.

Summary: Why Choose YISZHE Screw Roofing Nail for Your Bulk Projects?

- Superior holding power and fatigue resistance in every climate zone

- Best-in-class cost of roofing nails for large volume roofers

- Full customization for your project or resale specifications

- Strict international certifications, ISO/ANSI-compliant production

- Global case-proven performance with reference projects (on request)

Click to view detailed technical data & samples »

References & Further Reading

- Roofing Contractor Magazine (2024): Steel Nails Enhance Industrial Roofs

- Building Product Advisor (2024):

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025