Aug . 21, 2025 20:40 Back to list

Premium Bulk Roofing Nails for Sale - Low Cost

Strategic Procurement of Roofing Fasteners: An Overview of Bulk Roofing Nails

In the vast landscape of construction and infrastructure development, the integrity of a structure often hinges on the quality of its smallest components. Among these, roofing fasteners play a pivotal role, ensuring durability and resilience against environmental stressors. For large-scale projects, commercial suppliers, and distributors, the strategic acquisition of roofing nails in substantial quantities is not merely a purchasing decision but a critical operational imperative. This comprehensive guide delves into the world of bulk roofing nails, exploring their industrial significance, technical specifications, and the nuanced factors that influence their procurement.

Understanding the dynamics of the market, including the competitive landscape for roofing nails for sale and the intricate cost of roofing nails, is essential for optimizing supply chains and ensuring project profitability. From material science to application methodologies, every facet contributes to the overall performance and longevity of a roofing system. This article aims to provide a deep dive for B2B decision-makers, offering insights into selecting the right fasteners, navigating supplier choices, and understanding the complete lifecycle of these indispensable construction elements.

Navigating the Evolving Landscape: Industry Trends in Roofing Fasteners

The roofing industry is in constant evolution, driven by technological advancements, stricter building codes, and a growing emphasis on sustainability. These forces directly impact the demand and specifications for bulk roofing nails. Current trends highlight a shift towards enhanced corrosion resistance, improved pull-out strength, and fasteners designed for compatibility with advanced roofing materials like synthetic underlayments and high-performance shingles.

- Material Innovation: The adoption of stainless steel, galvanized steel, and specialized coatings (e.g., polymer-coated or electro-galvanized) is becoming standard to combat environmental degradation, especially in coastal or high-humidity regions.

- Performance-Driven Design: Fasteners are increasingly engineered for specific applications, such as wind uplift resistance in high-wind zones, requiring optimized shank designs (e.g., ring shank, screw shank) and head configurations.

- Sustainability and Longevity: Demand for products with extended service life reduces waste and lowers the lifecycle cost of roofing. This includes fasteners that can match or exceed the lifespan of the roofing material itself.

- Automation Compatibility: With the rise of automated roofing installation equipment, there's a growing need for collation systems for bulk roofing nails, such as coil nails or strip nails, to ensure efficient, high-volume application.

These trends collectively underscore the importance of selecting not just any fasteners, but those precisely engineered to meet modern construction demands. Suppliers offering a diverse portfolio of roofing nails for sale that align with these evolving standards are crucial partners for any construction enterprise.

Unpacking the Essentials: Technical Specifications of Bulk Roofing Nails

The performance of roofing nails is directly tied to their technical specifications. For procurement specialists, a thorough understanding of these parameters is crucial to ensure compatibility, longevity, and adherence to building codes. Key specifications for bulk roofing nails include material composition, shank type, head diameter, length, and coating.

Material Composition

The choice of material dictates a nail's strength, corrosion resistance, and suitability for various environments. Common materials include:

- Carbon Steel: Most common, often galvanized for corrosion protection.

- Stainless Steel (304 & 316): Offers superior corrosion resistance, ideal for coastal areas or treated lumber, though at a higher cost of roofing nails.

- Aluminum: Lighter, non-corrosive, suitable for aluminum roofing or flashing.

- Copper: Used for copper roofing or architectural details where aesthetic matching is desired.

Shank Type

- Smooth Shank: Basic holding power, commonly used for asphalt shingles.

- Ring Shank (Annular Ring): Features rings along the shank for enhanced pull-out resistance, critical for wind uplift.

- Screw Shank (Helical): Offers superior holding power, ideal for demanding applications, which is the specialty of our Screw Roofing Nail product. The helical thread acts like a screw, providing exceptional resistance against withdrawal.

Head Type and Size

Large, flat heads are characteristic of roofing nails, providing a wide bearing surface to prevent pull-through of roofing materials. Standard head diameters range from 7/16" to 1/2".

Length and Gauge

Nail length must be sufficient to penetrate the roofing material and adequately secure into the decking. Common lengths range from 1 inch to 2.5 inches. Gauge refers to the nail's thickness, with lower numbers indicating a thicker nail (e.g., 10-gauge is thicker than 12-gauge).

Coatings and Finishes

Coatings primarily serve to enhance corrosion resistance and improve nail setting. Common types for bulk roofing nails include:

- Hot-Dipped Galvanized (HDG): Thick zinc coating providing excellent corrosion protection.

- Electro-Galvanized (EG): Thinner zinc coating, good for basic protection.

- Polymer Coatings: Applied for enhanced adhesion, rust prevention, and smoother driving.

Typical Specifications for Bulk Roofing Nails

| Parameter | Common Range/Type | Key Characteristic/Benefit |

|---|---|---|

| Material | Carbon Steel, Stainless Steel (304/316), Aluminum, Copper | Strength, corrosion resistance, specific application needs. |

| Shank Type | Smooth, Ring Shank, Screw Shank (Helical) | Holding power, withdrawal resistance, application suitability. |

| Gauge | 10-gauge, 11-gauge, 12-gauge | Nail thickness, affecting strength and material displacement. |

| Length | 1" to 2.5" (25mm to 65mm) | Penetration depth, securing roofing material to substrate. |

| Head Diameter | 7/16" (0.4375") to 1/2" (0.5") | Bearing surface, preventing pull-through. |

| Coating/Finish | Hot-Dipped Galvanized (HDG), Electro-Galvanized (EG), Polymer Coated | Corrosion resistance, ease of driving. |

| Compliance | ASTM F1667, ASTM F1945, Local Building Codes (e.g., IBC, IRC) | Quality, safety, and performance standards. |

Precision Engineering: The Manufacturing Process of Screw Roofing Nails

The production of high-quality bulk roofing nails, particularly the advanced Screw Roofing Nail, involves a meticulously controlled manufacturing process designed to ensure superior performance and durability. This process emphasizes precision at every stage, from raw material selection to final quality inspection, adhering to international standards like ISO and ANSI.

1. Raw Material Procurement and Preparation

The foundation of a high-quality nail lies in its raw material. We primarily utilize high-grade carbon steel wire rods (e.g., SAE 1008, SAE 1018) for their optimal balance of strength and ductility. For specialized applications requiring enhanced corrosion resistance, stainless steel grades like 304 or 316 are procured. Upon arrival, materials undergo rigorous inspection to confirm chemical composition and mechanical properties, ensuring they meet strict internal and industry benchmarks.

2. Wire Drawing

The raw steel wire, typically supplied in larger diameters, is drawn through a series of dies to achieve the precise final diameter (gauge) required for the specific roofing nail. This cold-working process strengthens the wire and prepares it for subsequent forming operations. Continuous monitoring ensures dimensional accuracy and surface finish.

3. Cold Heading

In the heading machine, a precise length of wire is cut, and one end is cold-forged under immense pressure to form the flat, broad head characteristic of a roofing nail. This process ensures the head is uniformly shaped and securely integrated with the shank, critical for preventing pull-through of roofing materials. This is a cold working process, not casting or CNC machining.

4. Thread Rolling (for Screw Shank Nails)

For Screw Roofing Nails, the shank is then fed into a thread rolling machine. Here, hardened dies are pressed against the nail shank, forming the distinct helical threads. This process does not remove material but displaces it, enhancing the material's grain structure and significantly increasing the nail's withdrawal resistance compared to smooth or ring shank nails. This superior holding power is a key technical advantage, providing enhanced fastening security and contributing to a longer service life for the entire roofing system.

5. Point Forming

The opposite end of the nail is then formed into a sharp point, typically a diamond or chisel point, facilitating easy penetration into roofing materials and decking without splitting. This is often done concurrently or immediately after heading.

6. Surface Treatment / Coating

To impart corrosion resistance and enhance durability, the nails undergo surface treatment. The most common methods for bulk roofing nails include:

- Hot-Dipped Galvanization (HDG): Nails are immersed in molten zinc, creating a thick, highly corrosion-resistant coating. This is the preferred method for outdoor applications where long-term durability is crucial.

- Electro-Galvanization (EG): A thinner zinc layer applied electrochemically, offering moderate corrosion protection.

- Polymer/Vinyl Coating: Applied for lubrication during driving and additional rust prevention.

7. Quality Control and Inspection

Throughout the entire manufacturing process, stringent quality control measures are implemented. This includes:

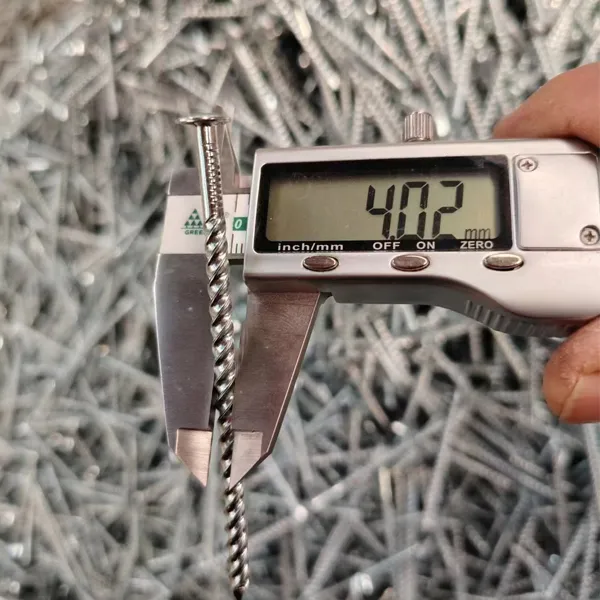

- Dimensional Checks: Regular measurements of length, gauge, head diameter, and thread profile (for screw nails).

- Mechanical Testing: Including pull-out strength tests (ASTM F1667), bend tests, and shear strength tests to ensure structural integrity.

- Corrosion Resistance Testing: Salt spray tests (ASTM B117) for coated nails to simulate accelerated weathering and assess coating effectiveness, ensuring extended service life even in harsh environments.

- Visual Inspection: Checking for defects, uniform coating, and overall finish.

Adherence to international standards such as ISO 9001 for quality management systems and relevant ANSI/ASTM standards (e.g., ASTM F1667 for Driven Fasteners) is paramount to ensuring product reliability and performance.

8. Packaging

Finished nails are counted, weighed, and packaged into appropriate container111s for bulk roofing nails, ensuring protection during transit and ease of handling on job sites or in distribution centers. For collated nails, precision coiling or strip formation is part of this final stage.

This rigorous manufacturing process ensures that each Screw Roofing Nail delivers consistent, high-performance fastening solutions, minimizing callbacks and enhancing the longevity of roofing installations, thereby reducing overall project cost of roofing nails in the long run.

Diverse Applications and Unmatched Technical Advantages of Bulk Roofing Nails

The versatility and robust performance of bulk roofing nails make them indispensable across a wide array of construction applications. While traditionally associated with residential roofing, their advanced designs, particularly screw shank varieties, extend their utility to more demanding commercial and industrial projects where superior fastening is paramount.

Typical Application Scenarios

- Asphalt Shingle Roofing: The most common application, where nails secure asphalt shingles to plywood or OSB sheathing. Screw shank nails offer enhanced blow-off resistance, crucial in high-wind regions.

- Underlayment and Flashing: Used to secure roofing underlayments (felt, synthetic) and various flashing materials (metal, rubber) to create a water-tight barrier.

- Siding Installation: While specialized siding nails exist, certain roofing nails can be adapted for siding, particularly for lightweight materials.

- General Construction Fastening: Beyond roofing, their strong holding power makes them suitable for general fastening needs where material pull-out is a concern.

- Commercial and Industrial Roofing: For larger, flatter roofs utilizing materials like EPDM, TPO, or modified bitumen, high-performance roofing nails are essential for securing insulation boards and membrane layers to the deck.

- Specialty Roofing: Including cedar shakes, slate, and tile roofing, though specific nail types (e.g., copper nails for slate) are often recommended.

The applicability extends to various industries where robust and durable fastenings are critical for structural integrity and long-term performance. While not direct 'petrochemical' or 'metallurgy' process components, the buildings and structures within these sectors rely on high-quality roofing, ensuring operational continuity and safety from environmental factors. The anti-corrosion properties and long service life contribute to reduced maintenance, indirectly supporting 'energy saving' through enhanced building envelope performance and longevity, rather than direct energy saving from process optimization.

Key Technical Advantages of Screw Roofing Nails

- Superior Withdrawal Resistance: The helical thread design of screw shank nails creates a mechanical lock with the wood substrate, providing significantly higher pull-out resistance compared to smooth or ring shank nails. This is crucial for resisting wind uplift and ensuring the roofing material stays securely fastened for decades.

- Enhanced Shear Strength: Manufactured from high-tensile steel, these nails exhibit excellent shear strength, preventing breakage or bending under load or during installation.

- Exceptional Corrosion Protection: Through advanced galvanization processes like hot-dipped galvanizing, our bulk roofing nails offer robust protection against rust and environmental degradation. This significantly extends the service life of the fastener and, by extension, the entire roofing system, even in harsh weather conditions or industrial atmospheres.

- Durability and Longevity: Designed to outlast the roofing material they secure, these nails ensure a stable and reliable roofing system. This translates to reduced maintenance costs and extended periods between roof repairs or replacements, directly impacting the long-term cost of roofing nails investment.

- Optimized for Power Tools: Many roofing nails for sale are available in collated formats (coil or strip), enabling rapid, efficient installation with pneumatic nail guns, significantly boosting productivity on large projects.

The strategic integration of these technical advantages ensures that our Screw Roofing Nails provide a foundation of reliability and long-term value, making them a preferred choice for discerning contractors and large-scale construction projects demanding the highest standards of performance and durability.

Strategic Sourcing: Comparing Bulk Roofing Nail Manufacturers

Choosing the right manufacturer for bulk roofing nails is a decision that impacts not only project timelines and budgets but also the long-term integrity of structures. While many suppliers offer roofing nails for sale, discerning the truly reliable partners from the rest requires a keen eye on several critical factors. Price alone, especially the immediate cost of roofing nails, should not be the sole determinant; long-term value, quality, and support are equally vital.

Key Factors in Manufacturer Evaluation:

- Quality Assurance & Certifications: Look for manufacturers with internationally recognized certifications such as ISO 9001 for quality management. Adherence to ASTM standards (e.g., ASTM F1667 for fasteners) is non-negotiable, ensuring products meet rigorous performance benchmarks.

- Manufacturing Capabilities: Assess their capacity for high-volume production, technological sophistication (e.g., advanced thread rolling, superior coating lines), and internal quality control protocols.

- Product Range & Customization: A reputable manufacturer should offer a wide variety of roofing nails (different lengths, gauges, coatings, and shank types) and the flexibility for custom orders to meet unique project specifications.

- Reputation and Experience: Longevity in the industry, positive customer testimonials, and a track record of successful bulk supply to major contractors or distributors are strong indicators of reliability. Our company, with over [e.g., 20 years] of experience in wire mesh and fastener manufacturing, has built a robust reputation for quality and consistency.

- Technical Support & After-Sales Service: Access to technical experts who can provide guidance on product selection, application best practices, and troubleshoot issues is invaluable.

- Supply Chain Reliability: For bulk orders, consistent delivery, efficient logistics, and transparent communication regarding lead times are crucial to keeping projects on schedule.

Why Partner with Us for Your Bulk Roofing Nail Needs?

Our commitment to excellence distinguishes us in the market for bulk roofing nails. We combine cutting-edge manufacturing technology with stringent quality control, producing Screw Roofing Nails that consistently exceed industry standards. Our robust production capacity ensures that even the largest bulk orders are fulfilled efficiently and on schedule, minimizing any potential disruptions to your project timelines. We understand that the initial cost of roofing nails is a factor, but our focus on superior quality and extended product lifespan ultimately delivers a lower total cost of ownership by reducing maintenance and replacement needs. We are proud of our comprehensive suite of certifications and a dedicated technical support team ready to assist with any product inquiries or custom requirements.

Tailored to Your Project: Custom Solutions for Bulk Roofing Nails

While standard specifications for bulk roofing nails cater to most general applications, large-scale commercial, industrial, or specialized roofing projects often demand bespoke solutions. Recognizing this need, leading manufacturers offer extensive customization options, allowing clients to procure fasteners that are perfectly aligned with unique structural, environmental, or material requirements.

Customization Parameters Include:

- Specific Lengths and Gauges: For varying roofing material thicknesses or decking types.

- Advanced Coatings: Beyond standard galvanization, specialized coatings for extreme corrosion resistance (e.g., polymer blends, ceramic coatings) can be applied for marine environments or industrial atmospheres.

- Material Variations: Utilizing specific stainless steel grades (e.g., 316 for higher chloride resistance), or even exotic alloys for ultra-demanding applications.

- Head Design Modifications: While usually flat, subtle changes for specific tools or aesthetic integration might be possible.

- Packaging & Collation: Custom bulk packaging sizes, or specific collation types (e.g., different coil counts, strip configurations) to optimize on-site efficiency with existing pneumatic tools.

The ability to provide customized roofing nails for sale signifies a manufacturer's technical prowess and commitment to client success. It moves beyond a one-size-fits-all approach to offer precision-engineered solutions that can significantly enhance project outcomes and potentially optimize the overall cost of roofing nails through efficiency gains.

Advantages of Bulk Ordering

For contractors, distributors, and large-scale builders, purchasing bulk roofing nails offers substantial benefits:

- Cost Efficiency: Significant per-unit cost reductions are achieved through economies of scale, directly lowering the overall cost of roofing nails for the project.

- Consistent Supply: Ensures a steady inventory, preventing project delays due to material shortages. This is particularly crucial for large or ongoing construction endeavors.

- Logistical Streamlining: Reduced frequency of orders and shipments simplifies supply chain management and minimizes transportation costs.

- Quality Uniformity: Bulk orders from a single, reputable manufacturer guarantee product consistency across the entire supply, ensuring uniform performance and compliance with specifications throughout the project.

Proven Performance: Case Studies & Client Success with Bulk Roofing Nails

The true testament to the quality and reliability of bulk roofing nails lies in their performance in real-world applications. Our Screw Roofing Nails have been integral to numerous successful projects, demonstrating their superior holding power, corrosion resistance, and overall durability. These case studies highlight how high-quality fasteners contribute to the longevity and structural integrity of diverse roofing systems.

Case Study 1: Large-Scale Commercial Warehouse Roof Replacement

Client: Major Logistics & Distribution Company, Coastal Region

Challenge: Replacing a 200,000 sq ft warehouse roof in a high-wind, high-humidity coastal environment. The previous roof suffered from frequent shingle blow-offs and fastener corrosion.

Solution: We supplied 500,000 units of 1.5-inch, Hot-Dipped Galvanized Screw Roofing Nails. The helical shank provided exceptional pull-out resistance, while the thick zinc coating ensured superior corrosion protection against saltwater spray.

Outcome: Two years post-installation, the roof has withstood multiple severe weather events without a single reported shingle failure or fastener issue. The enhanced durability significantly reduced maintenance costs and operational disruptions for the client, demonstrating the long-term value that offsets the initial cost of roofing nails.

Case Study 2: Residential Development in a Snow-Prone Area

Client: Residential Home Builder, Mountainous Region

Challenge: Constructing 50 new homes in an area prone to heavy snow loads and freeze-thaw cycles, requiring fasteners with maximum holding power to prevent shingle movement and ice dam formation.

Solution: Provided 250,000 units of 1.25-inch, Electro-Galvanized Screw Roofing Nails, specifically chosen for their superior grip in wood sheathing under varying temperature conditions.

Outcome: The homes have endured several harsh winters, with zero reports of shingle lifting or fastener failure, significantly enhancing homeowner satisfaction and reducing warranty claims for the builder. This showcases how the right choice of roofing nails for sale can improve construction quality and reduce long-term liabilities.

Client Feedback Highlight:

"Working with [Our Company Name - implied] for our bulk roofing nails supply has been a game-changer. Their Screw Roofing Nails are incredibly reliable, and we've seen a noticeable reduction in installation time due to their consistent quality. The technical support is excellent, and their understanding of our project-specific needs is unmatched. We factor in the lifetime value, and their product consistently reduces our overall cost of roofing nails for the development."

These testimonials and case studies underscore our commitment to delivering not just a product, but a reliable solution that contributes directly to the success and longevity of our clients' construction endeavors.

Unwavering Commitment to Quality: Certifications and Standards for Bulk Roofing Nails

In the B2B sector, trust is built on verifiable quality. For products like bulk roofing nails, adherence to stringent international standards and industry certifications is not just a regulatory requirement but a fundamental promise of reliability and performance. Our manufacturing processes and products are rigorously tested and certified to ensure they meet, and often exceed, global benchmarks.

Core Certifications and Compliance:

- ISO 9001:2015 Quality Management System: This certification signifies our commitment to consistent quality in all aspects of our operations, from design and development to production, delivery, and service. It provides a framework for ensuring that our roofing nails for sale consistently meet customer and regulatory requirements.

- ASTM Standards Compliance: Our roofing nails, especially the Screw Roofing Nail, are manufactured to comply with relevant ASTM (American Society for Testing and Materials) standards. Key standards include:

- ASTM F1667: Standard Specification for Driven Fasteners: Wood-Frame Construction. This covers general requirements for nails and staples used in wood construction, including dimensions, materials, and coatings.

- ASTM F1945: Standard Specification for Surface Discontinuities of Bolts, Screws, Studs, and Nuts (Inch Series). While primarily for bolts, principles of surface integrity and defects apply to fastener quality.

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus. Used for accelerated corrosion testing of our galvanized and coated nails, demonstrating their long-term resilience against environmental elements and validating their extended service life.

- ANSI Standards: American National Standards Institute (ANSI) provides guidelines for various industrial products, ensuring commonality and quality. Our products align with relevant ANSI dimensional and performance specifications where applicable.

- Local Building Codes (IBC, IRC): Our products are designed to meet the fastener requirements outlined in major building codes such as the International Building Code (IBC) and International Residential Code (IRC), ensuring compliance for projects across various jurisdictions.

Rigorous Internal Testing and Data-Driven Insights:

Beyond external certifications, our in-house laboratories conduct continuous testing to monitor product consistency and performance. This includes:

- Pull-Out Strength Tests: Quantifying the force required to withdraw a nail from various wood substrates, ensuring optimal holding power.

- Shear Strength Tests: Measuring the resistance to forces perpendicular to the nail's axis, critical for structural integrity.

- Coating Adhesion Tests: Verifying the bond of galvanized or other protective coatings to the nail's surface.

- Dimensional Accuracy: Utilizing precision instruments to confirm every batch of bulk roofing nails adheres to specified lengths, gauges, and head diameters.

This extensive testing framework, combined with our decades of experience in the fastener industry, reinforces our position as an authoritative and trustworthy supplier. Our commitment to quality ensures that when you invest in our roofing nails, you are investing in unparalleled durability and peace of mind, ultimately optimizing your long-term cost of roofing nails.

Building Partnerships: Comprehensive Customer Support and Warranty for Bulk Roofing Nails

Beyond delivering high-performance bulk roofing nails, our commitment extends to fostering long-term partnerships through unparalleled customer support and robust warranty programs. We understand that for B2B clients, reliable service is as crucial as product quality in ensuring seamless project execution and minimizing unforeseen costs.

Dedicated Technical and Sales Support:

- Expert Consultation: Our team of experienced technical advisors is available to assist with product selection, ensuring you choose the optimal Screw Roofing Nail specifications for your specific roofing materials, climate conditions, and building codes.

- Application Guidance: We provide comprehensive information on best practices for installation, tool compatibility, and safety protocols to maximize efficiency and performance on your job site.

- Order Management: Our sales representatives offer personalized support, managing your bulk roofing nails orders from initial inquiry to final delivery, ensuring clear communication and timely updates.

- Rapid Response: We pride ourselves on quick response times to inquiries, quotations, and support requests, understanding the time-sensitive nature of construction projects.

Guaranteed Quality: Our Warranty Promise

We stand behind the quality of every roofing nail we manufacture. Our products are backed by a comprehensive warranty that covers manufacturing defects and material integrity under normal use and installation conditions. This commitment reflects our confidence in the durability and performance of our fasteners, providing peace of mind for our clients.

- Long-Term Performance Guarantee: Our warranty typically extends for [e.g., 25 years or the life of the roofing material, whichever is less], covering structural integrity and corrosion resistance, affirming our confidence in the reduced cost of roofing nails over their lifespan.

- Defect Replacement: In the rare event of a product defect, we commit to prompt replacement, ensuring minimal disruption to your project schedule.

- Clarity and Transparency: Our warranty terms are clearly articulated, providing full transparency on coverage and claims procedures.

Delivery and Lead Times

Understanding the critical importance of timely delivery for large-scale projects, we maintain efficient production schedules and robust logistics networks. Our standard lead times for bulk roofing nails orders typically range from [e.g., 2-4 weeks], depending on order volume and customization requirements. For urgent projects, expedited shipping options may be available upon request. We work closely with our clients to coordinate delivery schedules that align with their project timelines, ensuring materials arrive precisely when needed, minimizing on-site storage requirements and streamlining workflow.

Common Inquiries: Frequently Asked Questions About Bulk Roofing Nails

To assist B2B professionals in making informed procurement decisions, we've compiled answers to frequently asked questions regarding bulk roofing nails. This section aims to address common concerns and clarify aspects related to our Screw Roofing Nail products and services.

Q1: What is the primary advantage of Screw Roofing Nails over other types?

A: The primary advantage lies in their superior withdrawal resistance. The helical (screw) shank creates a stronger mechanical lock within the wood substrate compared to smooth or ring shank nails. This significantly enhances resistance to wind uplift and material pull-through, leading to a more durable and long-lasting roofing system. This translates to lower maintenance and repair costs over the roof's lifespan, directly impacting the overall cost of roofing nails.

Q2: How do you ensure the corrosion resistance of your roofing nails?

A: We employ advanced galvanization techniques, primarily hot-dipped galvanizing (HDG), which applies a thick, uniform zinc coating providing excellent barrier protection against rust and corrosion. For specific high-corrosion environments, we also offer stainless steel options. All coatings undergo rigorous salt spray testing (e.g., ASTM B117) to ensure performance and longevity, which is crucial for roofing nails for sale designed for durability.

Q3: Can your bulk roofing nails be used with pneumatic nail guns?

A: Yes, many of our bulk roofing nails are available in collated formats (e.g., coil or strip nails) specifically designed for compatibility with standard pneumatic roofing nailers. This enables rapid and efficient installation, significantly boosting productivity on large-scale projects.

Q4: What is the typical delivery timeframe for bulk orders?

A: Standard lead times for bulk roofing nails orders typically range from 2-4 weeks, depending on the volume and any specific customization requirements. We recommend discussing your project timeline with our sales team to arrange a delivery schedule that aligns perfectly with your needs. We also offer expedited shipping options for urgent requirements.

Q5: Do you offer custom specifications for unique roofing projects?

A: Absolutely. We specialize in providing customized solutions. Clients can specify unique lengths, gauges, coating types, and even certain material compositions to meet the precise demands of their projects. Our technical team works closely with you to engineer fasteners that deliver optimal performance for your unique application.

Conclusion: The Foundation of Durable Roofing – Partnering for Bulk Roofing Nails

The success of any roofing project, whether residential, commercial, or industrial, fundamentally relies on the quality and reliability of its fastening components. As this comprehensive guide to bulk roofing nails illustrates, the choice of fastener significantly impacts the overall durability, safety, and long-term cost-effectiveness of a roofing system. Our Screw Roofing Nails embody the pinnacle of engineering excellence, offering superior withdrawal resistance, unparalleled corrosion protection, and consistent quality backed by rigorous testing and international certifications.

By understanding the critical technical parameters, the meticulous manufacturing process, and the myriad application advantages, B2B decision-makers can make informed choices that yield lasting value. We are committed to providing not just high-quality roofing nails for sale but also a partnership built on expertise, responsiveness, and a dedication to your project's success. The ultimate cost of roofing nails isn't just the purchase price, but the total lifecycle cost, which our products are designed to minimize through their exceptional longevity and performance.

For your next large-scale roofing endeavor, choose a supplier who prioritizes quality, precision, and partnership. Contact us today to discuss your specific bulk requirements and discover how our Screw Roofing Nails can provide the robust foundation your projects deserve.

References

- American Society for Testing and Materials (ASTM) International. ASTM F1667/F1667M, Standard Specification for Driven Fasteners: Wood-Frame Construction.

- International Organization for Standardization (ISO). ISO 9001:2015, Quality management systems — Requirements.

- International Code Council (ICC). International Building Code (IBC) and International Residential Code (IRC).

- Metal Roofing Alliance. Best Practices for Metal Roof Fasteners.

- National Roofing Contractors Association (NRCA). The NRCA Roofing Manual.

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025