Jan . 14, 2025 09:56 Back to list

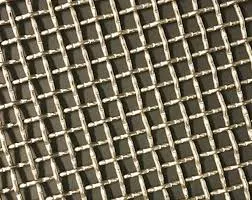

poultry wire mesh

Poultry wire mesh, often known as chicken wire, has been a staple in the agricultural and domestic settings for decades. This versatile material, typically constructed from galvanized steel or stainless steel, serves various purposes beyond the simple act of enclosing chickens. Its adaptability and durability make it a go-to solution for many DIY and professional projects.

Trustworthiness in the product is paramount, necessitating purchases from reputable suppliers who adhere to strict quality controls. Look for suppliers offering detailed specifications and compliance with international manufacturing standards. This guarantees not only the longevity of the wire mesh but also its safety for both animals and plants. In addition to traditional uses, the innovative application of poultry wire mesh has recently expanded into creative realms. Artists and designers have begun incorporating the material into sculptural projects due to its malleability and structural integrity. This trend highlights the mesh’s potential well beyond its agricultural roots, stimulating new industries and ideas. Ensuring effective use of poultry wire mesh involves continuous learning and adaptation to emerging technologies and methods. Workshops, online courses, and community forums offer invaluable insights and troubleshooting tips, allowing users to harness the full potential of this material in a variety of projects. Ultimately, poultry wire mesh remains a testimony to the blend of traditional and contemporary practices. Its multifaceted nature proves indispensable in both practical applications and creative endeavors, promising innovation while preserving its fundamental qualities. Leveraging this knowledge ensures the highest standards of quality and functionality in every project undertaken with this enduring material.

Trustworthiness in the product is paramount, necessitating purchases from reputable suppliers who adhere to strict quality controls. Look for suppliers offering detailed specifications and compliance with international manufacturing standards. This guarantees not only the longevity of the wire mesh but also its safety for both animals and plants. In addition to traditional uses, the innovative application of poultry wire mesh has recently expanded into creative realms. Artists and designers have begun incorporating the material into sculptural projects due to its malleability and structural integrity. This trend highlights the mesh’s potential well beyond its agricultural roots, stimulating new industries and ideas. Ensuring effective use of poultry wire mesh involves continuous learning and adaptation to emerging technologies and methods. Workshops, online courses, and community forums offer invaluable insights and troubleshooting tips, allowing users to harness the full potential of this material in a variety of projects. Ultimately, poultry wire mesh remains a testimony to the blend of traditional and contemporary practices. Its multifaceted nature proves indispensable in both practical applications and creative endeavors, promising innovation while preserving its fundamental qualities. Leveraging this knowledge ensures the highest standards of quality and functionality in every project undertaken with this enduring material.

Next:

Latest news

-

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025