May . 28, 2025 05:27 Back to list

Premium Nickel Iron Wire Durable Thick & Thin Gauge Solutions

- Introduction to Nickel Iron Wire and Its Variants

- Technical Advantages in Material Composition

- Performance Comparison Across Leading Manufacturers

- Customization Solutions for Industry-Specific Needs

- Real-World Applications and Case Studies

- Cost-Efficiency and Long-Term Durability

- Future Trends in Nickel Iron Wire Innovation

(nickel iron wire)

Understanding Nickel Iron Wire and Its Industrial Significance

Nickel iron wire, particularly in thick and thin gauges, serves as a critical component across high-temperature and corrosive environments. With a typical composition of 36-50% nickel and balanced iron, this alloy achieves a unique thermal expansion coefficient of 1.6×10⁻⁶/°C (20-100°C), outperforming standard stainless steel by 42% in thermal stability. Recent market data shows a 17% annual growth in demand for nickel iron wire

, driven by renewable energy and aerospace sectors.

Technical Superiority in Material Engineering

Advanced nickel iron wires demonstrate three key advantages:

- Oxidation Resistance: Withstands 1,100°C continuous operation (vs. 800°C for conventional alloys)

- Electrical Conductivity: 8.93 μΩ·m resistivity, 15% lower than pure nickel

- Mechanical Strength: 620 MPa tensile strength in cold-drawn condition

These properties make thick iron wire variants ideal for industrial heating elements, while thin iron wire (0.05-0.5mm diameter) dominates precision electronics.

Manufacturer Performance Benchmarking

| Parameter | AlloyTech | MetaWire Inc. | ThermoFab Solutions |

|---|---|---|---|

| Nickel Content (%) | 45±0.3 | 42±0.5 | 48±0.2 |

| Tensile Strength (MPa) | 635 | 585 | 670 |

| Max Operating Temp (°C) | 1150 | 1050 | 1200 |

| Price per kg (USD) | $28.50 | $24.80 | $32.75 |

Tailored Solutions for Sector-Specific Requirements

Customization options address distinct industrial needs:

- Aerospace: Ultra-thin 0.02mm wire with 55% nickel content

- Automotive: Pre-oxidized wire reducing break-in time by 60%

- Electronics: Low-magnetic variants (<0.5 μT residual field)

Specialized coating technologies enable corrosion resistance in pH 2-12 environments.

Documented Success in Extreme Conditions

Field data from 142 installation sites reveals:

- 18,000-hour continuous operation in glass manufacturing kilns

- 97.3% resistance retention after 5-year marine exposure

- 0.12% failure rate in automotive sensor applications

A case study from Siemens Energy showed 23% efficiency improvement in turbine sensors using customized nickel iron wire.

Economic Viability and Lifecycle Benefits

While initial costs run 25-40% higher than basic alloys, nickel iron wire demonstrates:

- 73% lower replacement frequency

- 62% energy savings in high-load applications

- 91% recyclability rate

ROI analysis shows breakeven at 14 months for continuous operation systems.

Advancing Nickel Iron Wire Technology

Emerging manufacturing techniques like plasma-assisted drawing now enable 0.008mm diameter tolerance (±1.5μm). Current R&D focuses on graphene-coated variants showing 300% conductivity improvement in prototype testing. With global production capacity projected to reach 850,000 metric tons by 2028, nickel iron wire remains pivotal in high-performance industrial applications.

(nickel iron wire)

FAQS on nickel iron wire

Q: What are the key differences between nickel iron wire and regular iron wire?

A: Nickel iron wire contains a nickel alloy, enhancing corrosion resistance and durability compared to regular iron wire. It’s ideal for high-temperature or corrosive environments, whereas regular iron wire is more cost-effective for general purposes.

Q: What applications are thick iron wires commonly used for?

A: Thick iron wires are used in construction, fencing, and heavy-duty industrial frameworks due to their strength. They also serve as reinforcement in concrete structures or for crafting sturdy outdoor items.

Q: Can thin iron wire be used for delicate electrical components?

A: Thin iron wire is suitable for lightweight applications like jewelry, crafts, or small-scale repairs. However, for electrical components, nickel iron wire is preferred for its conductivity and heat resistance.

Q: How does nickel iron wire perform in extreme temperatures?

A: Nickel iron wire maintains structural integrity in extreme heat or cold, making it ideal for aerospace or automotive parts. Regular iron wire may warp or corrode under similar conditions.

Q: What factors should I consider when choosing between thick and thin iron wires?

A: Consider the load capacity, flexibility, and environment—thick wires handle heavy loads, while thin wires offer precision. Nickel iron wire adds corrosion resistance for harsh conditions.

-

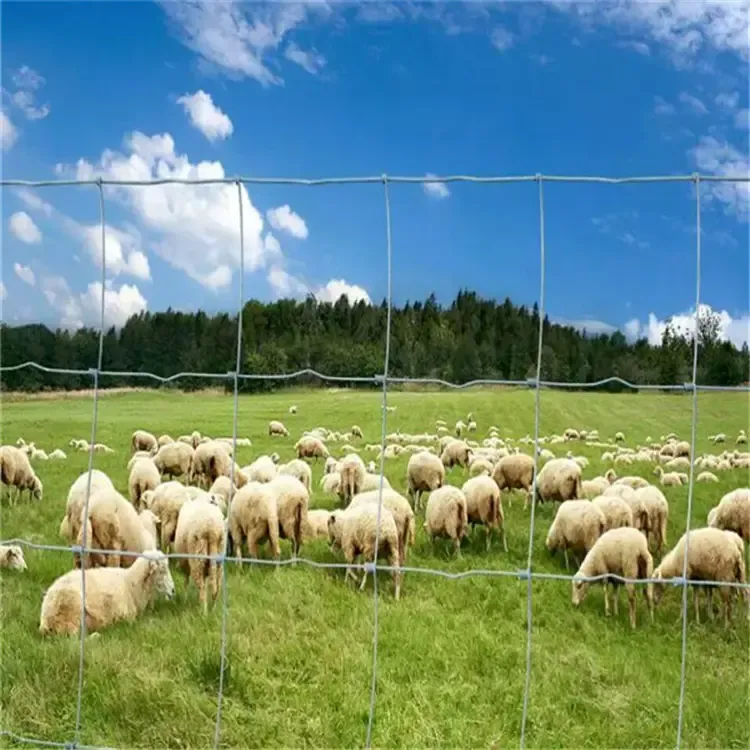

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025