Aug . 18, 2024 14:40 Back to list

Leading Manufacturer of High-Quality Diamond Mesh for Various Applications

The Significance of Diamond Mesh Manufacturers in Modern Industry

Diamond mesh, known for its versatility and strength, is a crucial element in various industries, including construction, agriculture, manufacturing, and security. The demand for high-quality diamond mesh products has led to a rise in specialized manufacturers capable of producing these essential materials. In this article, we will explore the significance of diamond mesh manufacturers, their production processes, and the applications of their products.

Understanding Diamond Mesh

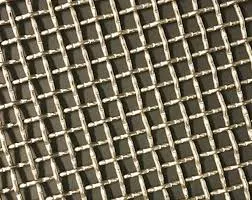

Diamond mesh refers to a type of netting characterized by its diamond-shaped openings, which provide both strength and flexibility. This design allows for adequate airflow while retaining structural integrity. It is commonly made from various materials, including steel, aluminum, and plastic, making it suitable for a wide range of applications.

Role of Diamond Mesh Manufacturers

The role of diamond mesh manufacturers is pivotal in ensuring that the products meet the necessary standards for different applications. These manufacturers specialize in the production of various kinds of diamond mesh, each tailored to specific industry needs. For instance, in construction, diamond mesh is essential for reinforcing concrete structures, while in agriculture, it can be used as fencing to protect crops from animals.

Production Processes

The production of diamond mesh involves several key steps, starting from material selection to the final treatment processes. High-quality raw materials are critical, as they directly impact the durability and effectiveness of the finished product.

1. Material Selection Manufacturers often choose materials such as galvanized steel for its rust resistance or vinyl-coated wire for enhanced weather resistance, depending on the intended use.

diamond mesh manufacturer

2. Weaving Process The weaving process is crucial in determining the quality of the diamond mesh. Advanced machinery is employed to create uniform diamond shapes, ensuring that the mesh is both strong and flexible.

3. Finishing After weaving, the mesh undergoes finishing processes like galvanization or powder coating to enhance durability and resistance to environmental factors. These treatments not only improve the lifespan of the product but also its aesthetic appeal.

4. Quality Control Reputable manufacturers implement stringent quality control measures. Each batch of diamond mesh is tested for strength, flexibility, and other relevant parameters to ensure it meets industry standards before reaching customers.

Applications of Diamond Mesh

The applications of diamond mesh are vast and varied. In construction, it serves as a protective barrier and reinforcement for concrete walls and structures. In agriculture, it acts as fencing material to safeguard crops and livestock. The mesh is also widely used in landscaping for gardens, where it can support climbing plants and protect delicate growth from pests.

Moreover, diamond mesh finds its role in industrial settings as a form of secondary containment for hazardous materials, ensuring safety and compliance with environmental regulations. In the security sector, it can be used for fencing around properties to deter intruders while providing visibility for monitoring.

Conclusion

The importance of diamond mesh manufacturers cannot be overstated. They play a crucial role in producing high-quality products that serve various sectors of the economy. As industries continue to evolve and demand safer, more efficient materials, the expertise of diamond mesh manufacturers will remain a cornerstone in facilitating growth and innovation. By providing durable and versatile solutions, these manufacturers contribute significantly to advancements in construction, agriculture, security, and beyond. The continued investment in technologies and processes among these manufacturers promises a bright future for diamond mesh applications across industries.

-

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025