Aug . 31, 2025 04:20 Back to list

Hexagonal Wire Mesh: Durable & Versatile Fencing Solutions

Introduction to Hexagonal Wire Mesh

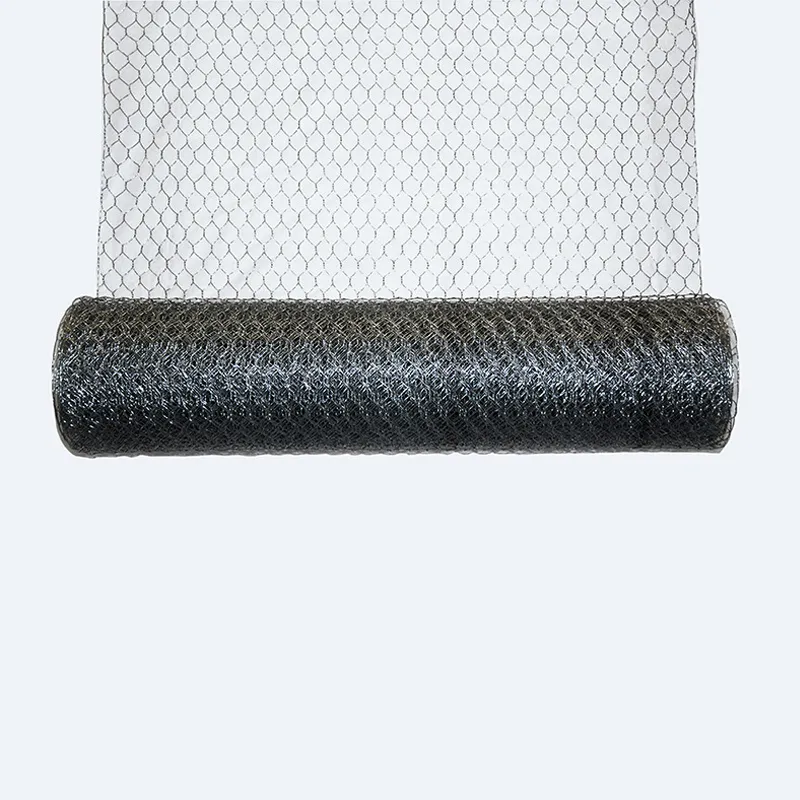

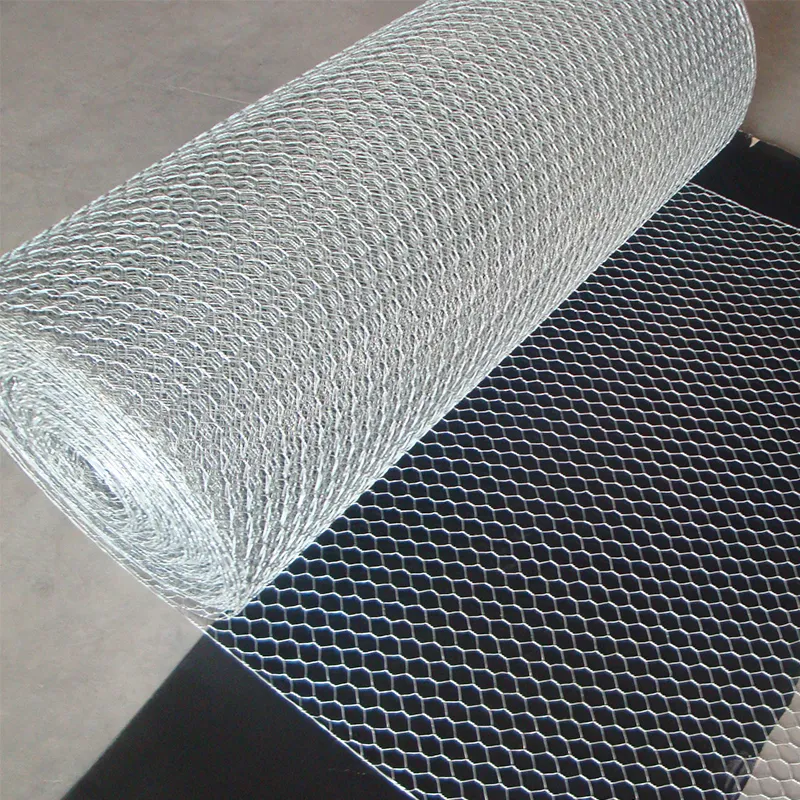

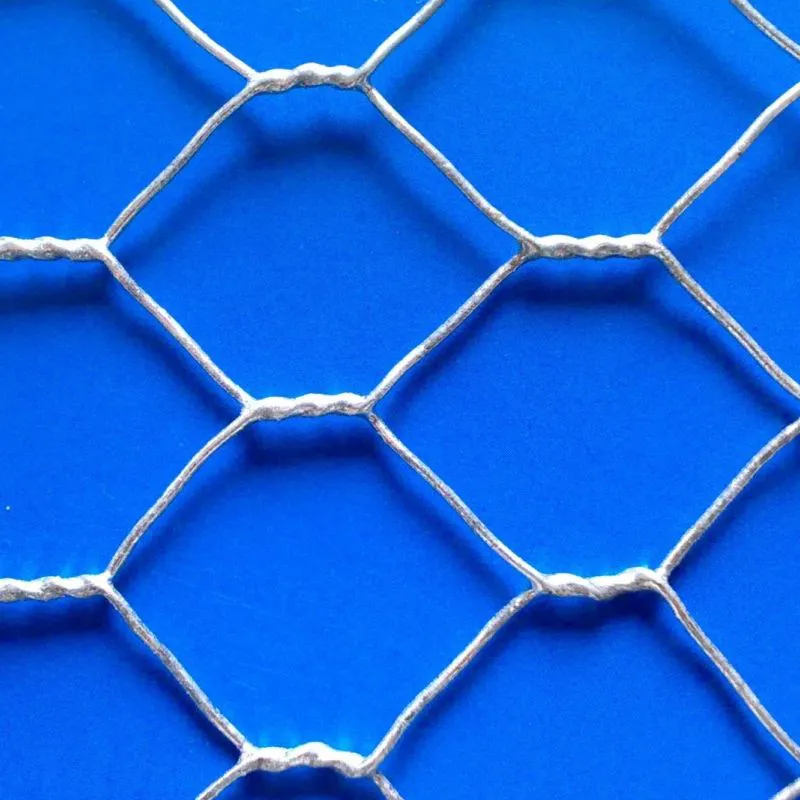

Hexagonal wire mesh, also widely recognized as chicken mesh or hexagonal wire netting, stands as a versatile and indispensable material across a multitude of industrial and commercial applications. Its unique double-twist hexagonal weave structure provides exceptional strength-to-weight ratio, flexibility, and durability, making it an ideal choice for fencing, animal enclosures, gabion baskets, and plaster reinforcement. This material is engineered to meet rigorous industry demands, offering superior resistance to corrosion and environmental stressors. Our commitment as a leading hexagonal wire netting factory is to deliver products that not only meet but exceed global quality benchmarks.

Industry Trends and Market Dynamics

The market for hexagonal wire mesh is currently experiencing robust growth, driven by increasing demand from infrastructure development, agricultural advancements, and environmental protection initiatives. Key trends include a rising preference for galvanized and PVC-coated options due to enhanced longevity and resistance to harsh weather conditions. There's also a growing emphasis on sustainable manufacturing practices within the hexagonal wire netting factory landscape, aligning with global environmental standards. Innovation in material science continues to improve tensile strength and elasticity, broadening application possibilities. The agricultural sector, particularly poultry farming, remains a significant consumer of chicken mesh, emphasizing the need for safe, durable, and cost-effective containment solutions.

- Growing demand in civil engineering for gabion structures and erosion control.

- Increased adoption of PVC-coated meshes for corrosive environments.

- Emphasis on lightweight yet high-strength materials to reduce logistical costs.

- Digitalization of supply chains for faster delivery and improved traceability.

Detailed Manufacturing Process of Hexagonal Wire Mesh

The production of high-quality hexagonal wire mesh involves a meticulously controlled process, ensuring product integrity and performance.

1. Material Selection

The foundation of superior hexagonal wire mesh lies in the selection of premium raw materials. We primarily utilize low carbon steel wire, typically Q195 or Q235 grade, renowned for its excellent ductility and workability. For applications requiring enhanced corrosion resistance, stainless steel wires (e.g., SS304, SS316) are employed. All raw materials undergo stringent quality checks to ensure compliance with international standards such as ASTM A641 for galvanized wire.

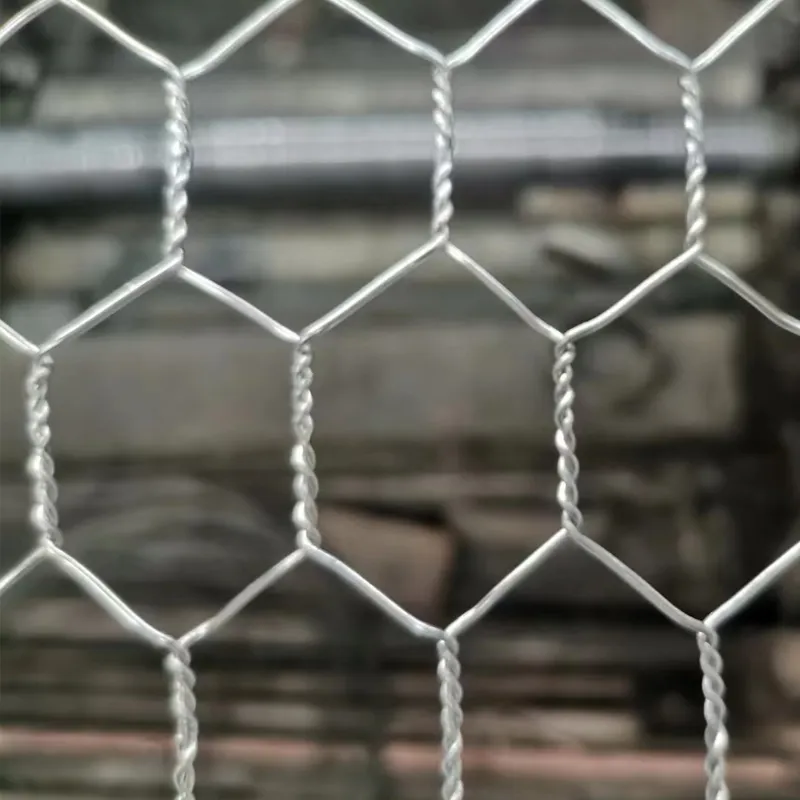

2. Weaving Process (Double Twist)

The core of hexagonal wire mesh production is the specialized double-twist weaving machinery. This process involves intertwining adjacent wires at least twice, forming robust hexagonal apertures. This double-twist mechanism prevents unraveling, even if a wire is cut, enhancing the mesh's structural integrity and safety. Our state-of-the-art machines ensure precise mesh aperture size and consistent weave tension across the entire roll.

3. Surface Treatment (Galvanization/PVC Coating)

Post-weaving, the mesh undergoes surface treatment to impart corrosion resistance and extend service life.

- Electro Galvanization: A cost-effective method providing a uniform zinc coating (typically 10-20 g/m²).

- Hot-Dip Galvanization: Offers superior corrosion protection with a thicker zinc layer (40-60 g/m² or more), significantly extending service life in demanding environments. This meets ISO 1461 standards.

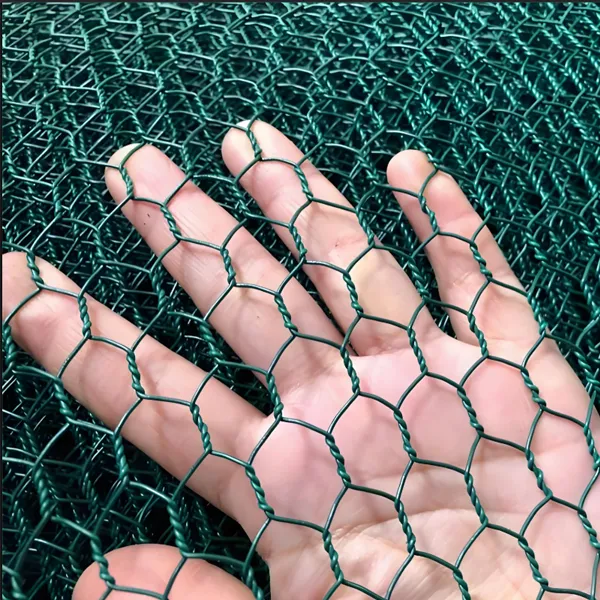

- PVC Coating: A further layer of protection applied over galvanized wire, available in various colors. PVC coating enhances corrosion resistance, UV stability, and aesthetic appeal, often used in coastal regions or areas with high chemical exposure.

4. Edge Reinforcement

To ensure structural integrity and ease of installation, the edges of the hexagonal wire mesh are reinforced. This often involves using a heavier gauge selvedge wire or additional twists to prevent fraying and maintain shape during handling and application.

5. Quality Control and Testing

Every batch of hexagonal wire mesh undergoes rigorous testing to ensure it meets both internal quality protocols and international standards. This includes:

- Tensile Strength Test: To verify the wire's resistance to breaking under tension (e.g., ASTM A975).

- Zinc Coating Adhesion Test: Ensuring the galvanized layer is firmly bonded to the steel.

- Mesh Aperture and Wire Diameter Measurement: Conforming to specified dimensions.

- Salt Spray Test: For PVC-coated meshes, assessing corrosion resistance in accelerated conditions.

Our products are certified to ISO 9001 quality management standards, assuring consistency and reliability. The service life of galvanized hexagonal wire mesh typically ranges from 10-20 years, while PVC-coated variants can extend beyond 25 years, depending on environmental conditions.

Technical Specifications and Parameters

Understanding the technical specifications of hexagonal wire mesh is crucial for selecting the appropriate product for your application. Below is a comprehensive table outlining typical parameters.

| Parameter | Description | Common Values / Standards |

|---|---|---|

| Material | Low carbon steel, Stainless steel | Q195, Q235, SS304, SS316 |

| Wire Diameter (Gauge) | Thickness of the wire used, measured in mm or BWG. | 0.6mm - 4.0mm (BWG 23-8) |

| Mesh Aperture (Opening) | Size of the hexagonal opening, measured in mm or inches. | 10mm - 100mm (3/8" - 4") |

| Surface Treatment | Corrosion protection method. | Electro Galvanized, Hot-Dip Galvanized, PVC Coated |

| Tensile Strength | Maximum stress wire can withstand before breaking. | 380-550 N/mm² (ASTM A641) |

| Roll Width | Standard width of the mesh rolls. | 0.5m - 2.0m (1.6ft - 6.5ft) |

| Roll Length | Standard length of the mesh rolls. | 20m - 50m (65ft - 164ft) |

| Zinc Coating Weight | Amount of zinc per square meter for galvanized products. | 10-60 g/m² (Electro), 60-300 g/m² (Hot-dip) |

Application Scenarios and Industry Use Cases

The versatility of hexagonal wire mesh makes it suitable for a broad spectrum of industries, providing effective solutions for protection, reinforcement, and containment.

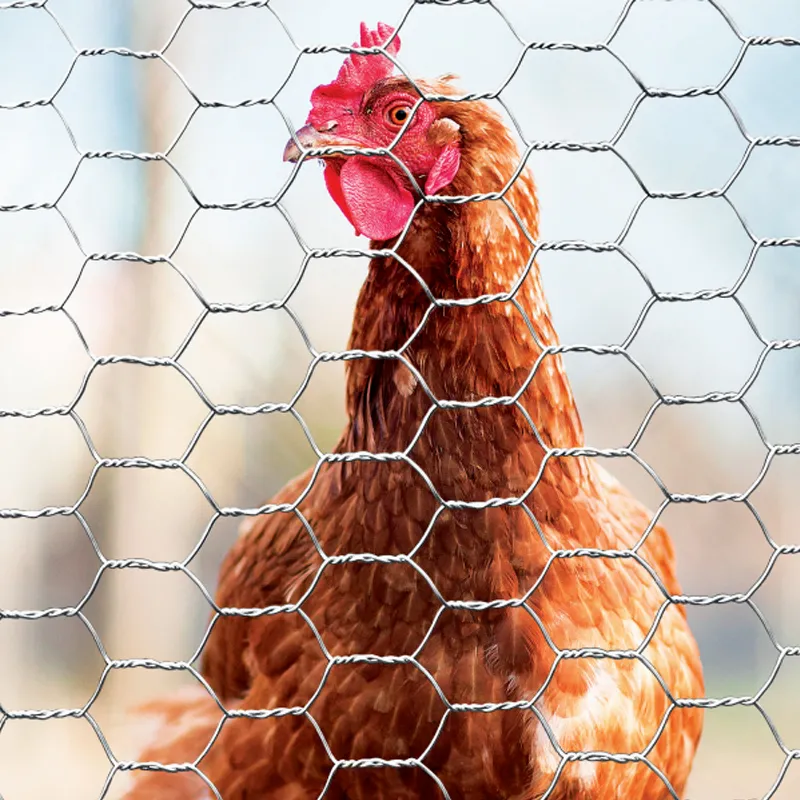

- Agriculture & Animal Husbandry: Primarily as chicken mesh for poultry enclosures, rabbit fences, and general farm fencing. Its flexible nature allows for easy installation around varied terrain, crucial for livestock management.

- Civil Engineering & Construction: Used extensively in the formation of gabion baskets for retaining walls, river bank protection, and erosion control. Its ability to conform to ground movement makes it ideal for stabilizing slopes and preventing landslides, offering significant energy saving in construction and maintenance.

- Industrial Applications: Filtration media, sieve plates, and protective covers in industries such as petrochemical, metallurgy, and mining. The precise mesh apertures ensure effective separation and safety.

- Water Supply & Drainage: Reinforcement in concrete structures for channels and pipes, contributing to the longevity and integrity of water management systems.

- Horticulture & Landscaping: Tree guards, garden fencing, and support for climbing plants. The aesthetic appeal of PVC-coated mesh is particularly valued here.

- Plaster Reinforcement: Used as a backing for plastering walls, providing a strong bond and preventing cracks. Its flexibility allows it to adapt to uneven surfaces.

Technical Advantages and Benefits

Choosing hexagonal wire mesh from a reputable hexagonal wire netting factory offers distinct advantages:

- Exceptional Flexibility: The double-twist weave allows the mesh to be easily formed and installed, adapting to irregular surfaces without losing structural integrity.

- High Strength-to-Weight Ratio: Provides robust protection and containment without excessive bulk, simplifying handling and reducing transportation costs.

- Corrosion Resistance: Galvanized and PVC-coated options ensure longevity even in harsh, corrosive environments, reducing maintenance requirements and extending service life.

- Unraveling Resistance: The double-twist interweaving prevents the mesh from unraveling if a wire is cut, maintaining its structural integrity and effectiveness.

- Cost-Effectiveness: Compared to other fencing or reinforcement materials, hexagonal wire mesh offers a durable, long-term solution at a competitive price point, providing excellent value over its service life.

- Breathability and Visibility: Its open structure ensures good airflow and visibility, important for animal enclosures and certain architectural applications.

Vendor Comparison and Selection Guide

Selecting the right supplier for hexagonal wire mesh is paramount to project success. While specific product lines may vary, here's a general comparison matrix to guide decision-makers when evaluating hexagonal wire netting factory options.

| Feature | Our Company (Yiszhe Wire Mesh) | Typical Competitor A | Typical Competitor B |

|---|---|---|---|

| Certifications | ISO 9001:2015, ASTM, CE | ISO 9001 | Basic QC |

| Material Quality | Premium Low Carbon Steel, SS304/SS316 options | Standard Low Carbon Steel | Economical Steel |

| Galvanization Type | Hot-Dip (Before/After weaving), Electro | Mainly Electro, some Hot-Dip Before | Electro Galvanized |

| PVC Coating Quality | UV-stable, Anti-aging, Uniform thickness | Standard PVC, limited UV resistance | Thin PVC layer |

| Customization Options | Extensive (mesh size, wire dia, coating, color, roll dim.) | Limited (standard sizes) | Minimal |

| After-Sales Support | Comprehensive, Warranty, Technical assistance | Standard support | Basic contact |

Customized Solutions and Engineering Capabilities

Understanding that standard products may not always meet unique project requirements, our hexagonal wire netting factory specializes in providing tailored solutions. Our engineering team works closely with clients to design and produce custom hexagonal wire mesh to exact specifications.

Customization Options Include:

- Specific Mesh Apertures: From fine chicken mesh for small birds to larger openings for heavy-duty applications.

- Non-Standard Wire Diameters: To achieve particular tensile strength or flexibility characteristics.

- Specialized Coatings: Beyond standard galvanization and PVC, we can explore other protective layers for extreme environments.

- Custom Roll Dimensions: Tailored widths and lengths to minimize waste and simplify installation on-site.

- Material Composition: Offering options like high-tensile steel or specific stainless steel grades for niche applications requiring particular chemical resistance.

Our CAD/CAM capabilities and experienced technical staff enable us to translate complex design requirements into precision-manufactured products, ensuring optimal performance and cost-efficiency for every unique project.

Real-World Application Case Studies

Our expertise in hexagonal wire mesh has been validated through numerous successful projects globally.

Case Study 1: Gabion Wall for River Bank Stabilization (Client: Major Civil Engineering Firm, Europe)

A significant challenge faced by our client was stabilizing a river bank susceptible to severe erosion. We supplied large quantities of heavy-gauge, hot-dip galvanized hexagonal wire mesh, formed into gabion baskets. These gabions were filled with local stone and strategically placed to form robust retaining walls. The inherent flexibility of the double-twist mesh allowed for natural ground settlement without compromising structural integrity. Post-installation, the river bank has remained stable for over 15 years, significantly exceeding the client's expectations for corrosion resistance and durability in a constantly wet environment.

Case Study 2: Poultry Farm Enclosures (Client: Large-Scale Agricultural Enterprise, Asia)

A major agricultural client required secure and humane enclosures for a large-scale poultry operation. We provided thousands of meters of PVC-coated chicken mesh with a specific aperture size to prevent escape while ensuring adequate ventilation and predator protection. The PVC coating offered excellent resistance to agricultural chemicals and extended the service life significantly. The client reported a noticeable reduction in maintenance costs and improved animal welfare due to the mesh's robust yet flexible nature, making installation efficient across varied terrains.

Quality Assurance and Certifications

Our unwavering commitment to quality is the cornerstone of our operations as a leading hexagonal wire netting factory. We adhere to the most stringent international quality management systems and product standards.

- ISO 9001:2015 Certified: Our entire manufacturing process, from raw material procurement to final packaging, is governed by ISO 9001:2015 quality management standards, ensuring consistent product quality and customer satisfaction.

- Compliance with ASTM Standards: Our hexagonal wire mesh products conform to relevant ASTM (American Society for Testing and Materials) standards, including ASTM A975 for metallic-coated steel wire gabions and revet mattresses.

- CE Mark: For products destined for the European market, we ensure compliance with CE marking requirements, signifying conformity with health, safety, and environmental protection standards.

- Comprehensive Internal QC: Beyond external certifications, we implement a multi-stage internal quality control process, including raw material inspection, in-process monitoring, and final product testing, to guarantee every roll of hexagonal wire mesh meets specifications.

Frequently Asked Questions (FAQ)

- Q1: What is the primary difference between galvanized and PVC-coated hexagonal wire mesh?

- A1: Galvanized hexagonal wire mesh uses a zinc coating for corrosion resistance. PVC-coated mesh has an additional layer of plastic over the galvanized wire, offering superior corrosion, UV, and chemical resistance, and is available in various colors for aesthetic purposes. PVC coating typically extends the service life significantly.

- Q2: Can I get custom sizes or specifications for hexagonal wire mesh?

- A2: Yes, as a dedicated hexagonal wire netting factory, we offer extensive customization options including specific mesh apertures, wire diameters, roll dimensions, and specialized coatings to meet unique project requirements.

- Q3: What are the typical lead times for large orders?

- A3: Lead times vary depending on order volume and customization. For standard products, typical lead times range from 3-5 weeks. For large or highly customized orders, please contact our sales team for a precise timeline.

- Q4: How do you ensure the quality of your chicken mesh products?

- A4: Our quality assurance process includes strict raw material inspection, in-line process control, and final product testing against ISO 9001 and ASTM standards. We also provide material test certificates upon request.

Ordering, Lead Time, and Customer Support

We streamline the ordering process for all our hexagonal wire mesh products to ensure efficiency and transparency.

Ordering Process:

- Inquiry Submission: Provide your specifications (mesh size, wire diameter, coating, quantity, application) via our website or direct contact.

- Quotation & Consultation: Our sales engineers will provide a detailed quote and offer technical advice.

- Order Confirmation: Upon agreement, a purchase order is processed.

- Production & Quality Control: Manufacturing commences with rigorous QC at each stage.

- Shipping & Delivery: Products are packaged securely and shipped according to agreed terms.

Lead Time & Fulfillment:

Standard orders of hexagonal wire mesh typically have a production and fulfillment lead time of 3 to 5 weeks from order confirmation. For expedited requirements or large-volume projects, please discuss your specific needs with our team, and we will endeavor to accommodate them. We maintain efficient logistics partnerships to ensure timely and secure delivery worldwide.

Customer Support:

Our dedicated customer support team is available from Monday to Friday, 9:00 AM to 5:00 PM (GMT+8). We offer comprehensive pre-sales consultation, technical assistance during product selection, and efficient after-sales service. Contact us via phone, email, or our website's inquiry form for prompt assistance.

Warranty and After-Sales Commitment

As a trusted hexagonal wire netting factory, we stand behind the quality and performance of our hexagonal wire mesh products.

Warranty Coverage:

- We provide a standard 1-year limited warranty against manufacturing defects for all our hexagonal wire mesh products from the date of purchase.

- Specific longer warranties may apply to certain specialized products or project-based agreements, detailed in the respective contract.

- This warranty covers material or workmanship failures under normal use and service conditions. It does not cover damage resulting from improper installation, misuse, accidents, or natural disasters.

After-Sales Support:

Our commitment extends beyond the sale. We offer comprehensive after-sales support, including:

- Technical Assistance: Guidance on installation best practices, maintenance, and troubleshooting.

- Product Information: Access to detailed product datasheets, installation guides, and safety information.

- Feedback Channel: A dedicated channel for customer feedback to ensure continuous improvement in our products and services.

Our goal is to build long-term partnerships by providing reliable products and exceptional customer service throughout the entire product lifecycle.

Conclusion

Hexagonal wire mesh, with its distinctive double-twist weave and robust material options, represents an engineering solution of choice for a diverse range of B2B applications. From critical infrastructure projects requiring durable gabion structures to agricultural sectors relying on efficient chicken mesh, its technical advantages in flexibility, strength, and corrosion resistance are unmatched. As a leading hexagonal wire netting factory, we are dedicated to advancing its capabilities through rigorous quality control, adherence to international standards, and continuous innovation in customized solutions. Partnering with us ensures access to superior products, comprehensive technical support, and a commitment to long-term performance and value.

References

- ASTM International Standards. "ASTM A975 - Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses (Metallic-Coated Steel Wire or Metallic-Coated Steel Wire With PVC Coating)."

- International Organization for Standardization. "ISO 9001:2015 - Quality management systems — Requirements."

- Maccaferri Gabions. "Gabion Technical Specifications and Design Principles." (General industry practice reference)

- Wire & Wire Products Association. "Technical Handbook for Wire Mesh Manufacturing." (General industry information)

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025