Aug . 30, 2025 04:20 Back to list

Durable Diamond Razor Wire for Ultimate Security

In high-stakes security applications, the demand for robust, reliable, and impenetrable perimeter solutions is paramount. Modern security challenges necessitate advanced deterrents that offer superior physical barriers and psychological discouragement. Among these, diamond razor wire stands out as a critical component in ensuring the integrity of protected areas. This article delves into the technical intricacies, application versatility, and strategic advantages of this essential security material, catering to B2B decision-makers and engineers seeking optimal security infrastructure.

Industry Trends in High-Security Perimeter Solutions

The global security perimeter market is experiencing significant growth, driven by increasing geopolitical tensions, industrial espionage, and the need for enhanced protection of critical infrastructure. Key trends include the integration of passive physical barriers with active surveillance systems, the development of anti-climb technologies, and a growing emphasis on materials offering extended service life and reduced maintenance. The market for high-security fencing, including razor wire solutions, is projected to reach USD 5.6 billion by 2027, with a Compound Annual Growth Rate (CAGR) of 6.5% from 2022. End-users are increasingly prioritizing solutions that balance high deterrence with cost-effectiveness and ease of deployment. There is also a distinct move towards sustainable and corrosion-resistant materials to minimize environmental impact and maximize longevity. This shift underscores the critical role of durable and effective barriers like diamond razor wire in modern security strategies. The convergence of physical and electronic security elements is also a major trend, where physical deterrents like razor wire complement advanced sensor systems to create multi-layered defenses.

Furthermore, the demand for specialized solutions tailored to specific environmental conditions – such as coastal regions requiring exceptional corrosion resistance or high-altitude areas needing UV-stable materials – is on the rise. This necessitates close collaboration between clients and expert razor wire suppliers to develop customized products that meet stringent performance criteria. The evolution of blade designs, coating technologies, and installation methods continually pushes the boundaries of what passive security can achieve.

Manufacturing Process Flow of Diamond Razor Wire

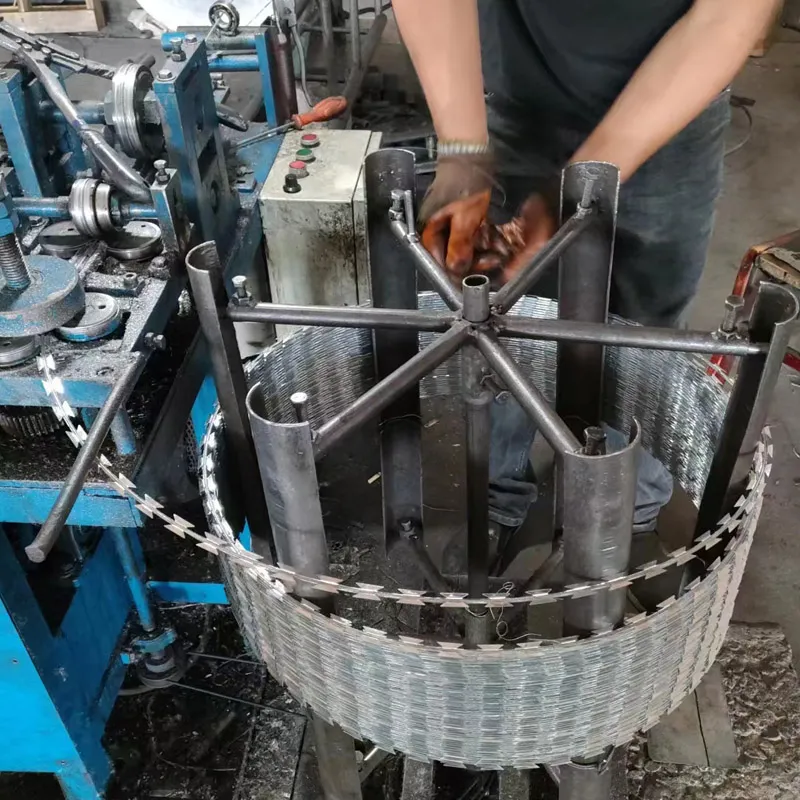

The production of diamond razor wire is a precise engineering process designed to ensure maximum deterrent effect and longevity. Unlike conventional barbed wire, razor wire involves specialized blade profiles and core wire strength.

Key Materials and Their Significance:

- High-Tensile Steel Core Wire: Typically, a galvanized or stainless steel wire with a tensile strength ranging from 1600-1900 MPa (Megapascals) is used. This provides the structural integrity and resistance to cutting or bending.

- Galvanized Steel Strips (Blade Material): Cold-rolled steel sheets, typically 0.5-0.6 mm thick, are hot-dip galvanized with a zinc coating of 200-275 g/m² for superior corrosion resistance. Alternatively, AISI 304 or 316 stainless steel is used for extreme environments.

- Optional PVC/Powder Coating: For enhanced corrosion protection, color coding, or aesthetic integration, a polymer coating can be applied post-galvanization.

Manufacturing Process Steps:

- Blade Stamping: High-precision presses stamp out the distinctive diamond-shaped blades from the galvanized or stainless steel strips. These blades are designed for maximum deterrence and feature sharpened edges.

- Blade Crimping onto Core Wire: The stamped blades are then mechanically crimped around the high-tensile core wire. This process ensures a secure, non-slip attachment of the blades to the central strand. Advanced machinery maintains precise spacing and crimping pressure.

- Coiling (Concertina Formation): The continuous razor wire is fed into specialized coiling machines that form it into a concertina coil. This involves spiraling the wire and then joining adjacent turns at regular intervals using metal clips (often galvanized steel or stainless steel) to create a robust, spring-like barrier. Common coil diameters range from 450mm to 900mm.

-

Quality Control and Testing: Each batch undergoes rigorous testing to meet international standards such as ISO 9001 for quality management and ASTM F1910-98 for razor wire. Key tests include:

- Tensile Strength Test: To verify the core wire's resistance to breaking.

- Zinc Coating Thickness Test: Ensures adequate corrosion protection (e.g., in accordance with ASTM A90/A90M).

- Salt Spray Test: Evaluates corrosion resistance over time (e.g., ASTM B117, typically 500-1000 hours for galvanized).

- Blade Adhesion Test: Confirms the blades are securely attached to the core wire.

- Packaging: Finished coils are compressed for transport efficiency and securely packaged, often wrapped in waterproof paper and hessian cloth, or placed in cartons.

Service Life: Due to the high-quality materials and rigorous manufacturing, standard galvanized diamond razor wire typically offers a service life of 7-15 years, while stainless steel variants can last 15-25+ years, even in harsh environmental conditions.

Target Industries & Advantages:

- Petrochemical Industry: Essential for securing refineries, storage tanks, and pipelines against sabotage and theft. The corrosion resistance of galvanized or stainless steel options ensures longevity in chemically aggressive environments.

- Metallurgy and Mining: Used to protect valuable assets, processing plants, and extraction sites. Its robust construction resists tampering and provides a formidable physical barrier.

- Water Supply & Drainage Facilities: Secures water treatment plants, reservoirs, and pumping stations, preventing unauthorized access that could lead to contamination or disruption of critical services. Its durability ensures long-term, low-maintenance protection.

- Military & Correctional Facilities: Provides the highest level of physical deterrence for high-security zones, effectively preventing escapes and unauthorized intrusions.

- Data Centers & Telecommunication Hubs: Protects sensitive equipment and proprietary information by creating an impenetrable perimeter against physical breaches.

Technical Specifications and Parameters

Understanding the precise technical parameters of diamond razor wire is crucial for specifying the correct product for a given security requirement. These specifications dictate the material's strength, corrosion resistance, and overall deterrent effectiveness.

| Parameter | Standard Galvanized (BTO-22) | Heavy Galvanized (CBT-65) | Stainless Steel (AISI 304) |

|---|---|---|---|

| Material | High-carbon steel core, Galvanized steel blade | High-carbon steel core, Heavy galvanized steel blade | Stainless steel core & blade |

| Core Wire Diameter | 2.5 mm ± 0.1 mm | 2.5 mm ± 0.1 mm | 2.5 mm ± 0.1 mm |

| Core Wire Tensile Strength | 1600-1900 MPa | 1600-1900 MPa | 1600-1900 MPa |

| Blade Thickness | 0.5 mm ± 0.05 mm | 0.6 mm ± 0.05 mm | 0.5 mm ± 0.05 mm |

| Zinc Coating (Blade) | 60-90 g/m² | 200-275 g/m² | N/A |

| Blade Type | Diamond (BTO-22) | Diamond (CBT-65) | Diamond (BTO-22 / CBT-65) |

| Coil Diameter (before extension) | 450 mm, 600 mm, 750 mm, 900 mm | 450 mm, 600 mm, 750 mm, 900 mm | 450 mm, 600 mm, 750 mm, 900 mm |

| Clips per Coil (typical 600mm) | 3 or 5 clips | 3 or 5 clips | 3 or 5 clips |

| Recommended Extension Length (per coil) | 8-10 meters | 8-10 meters | 8-10 meters |

| Service Life (Estimated) | 7-15 years | 15-20 years | 20-25+ years |

Note: Specifications are typical and may vary slightly based on specific product lines and manufacturer. Always consult the supplier for precise data.

Diverse Application Scenarios

The versatility of diamond razor wire makes it an indispensable asset across a multitude of industries requiring high-level security. Its adaptable installation methods allow for deployment in various configurations, including topping existing fences, standalone barriers, or integrated multi-layered systems.

- Critical Infrastructure Protection: Power plants, telecommunication centers, and water treatment facilities frequently employ razor wire to safeguard against vandalism, sabotage, and unauthorized entry. Its immediate visual deterrent combined with the physical barrier capability provides robust first-line defense.

- Industrial & Commercial Properties: Factories, warehouses, logistics hubs, and storage yards utilize razor wire to protect valuable inventory, equipment, and sensitive areas. It serves as a cost-effective yet highly effective deterrent against theft and intrusion.

- Government and Military Sites: High-security government buildings, military bases, border patrol zones, and correctional institutions rely on razor wire for perimeter security due to its extreme effectiveness in preventing breaches and unauthorized access. Its intimidating presence acts as a significant psychological barrier.

- Airport and Port Security: Securing vast perimeters of airports and seaports is crucial for national security and international trade. Razor wire, often deployed in conjunction with chain-link fences, prevents illegal entry and enhances overall security protocols.

- Residential High-Security Zones: While less common for typical residential use, high-profile private estates or diplomatic residences may employ razor wire for reinforced security.

Technical Advantages and Performance Metrics

The technical superiority of diamond razor wire stems from its design and material properties, offering distinct advantages over traditional security measures.

- Superior Deterrent Effect: The sharp, diamond-shaped blades present a formidable physical and psychological barrier. Its appearance alone discourages most attempts at intrusion, significantly reducing the likelihood of unauthorized access.

- Exceptional Physical Barrier: The concertina design, combined with high-tensile core wire, makes cutting or breaching extremely difficult without specialized tools and considerable effort, which typically triggers alarms or attracts attention. The unique blade geometry is designed to entangle and impede.

- Corrosion Resistance: Available in hot-dip galvanized and stainless steel (AISI 304, AISI 316) options, offering excellent resistance to rust and degradation in harsh weather conditions, coastal environments, or industrial settings. This ensures a prolonged service life and minimal maintenance requirements, contributing to lower lifecycle costs. Zinc coating adherence tests consistently demonstrate compliance with ASTM A90/A90M standards.

- Durability and Longevity: Manufactured from high-strength steel, it withstands significant physical stress and environmental exposure. The typical service life of up to 25 years for stainless steel variants outperforms many other fencing materials, proving its long-term reliability.

- Versatile Installation: Can be installed on top of existing fences, walls, or ground, adapting to various terrains and security requirements. Its modular coil design facilitates relatively quick deployment.

- Cost-Effectiveness: While the initial investment might be higher than standard barbed wire, the superior deterrence, extended service life, and reduced maintenance costs make it a highly cost-effective long-term security solution. It reduces the need for frequent repairs or replacements.

Vendor Comparison: Razor Wire and Barbed Wire Solutions

Choosing the right perimeter security solution often involves comparing different types of physical deterrents. While both razor wire and barbed wire serve as security enhancements, their technical specifications and performance characteristics vary significantly.

| Feature | Diamond Razor Wire | Standard Barbed Wire |

|---|---|---|

| Deterrent Level | High to Extreme (Physical & Psychological) | Moderate (Physical & Psychological) |

| Blade/Barb Design | Sharp, cutting blades (diamond, single, or crossed razor) | Pointed, piercing barbs (2 or 4 points) |

| Material Strength (Core Wire) | High-tensile steel (1600-1900 MPa) | Medium-tensile steel (approx. 500-700 MPa) |

| Resistance to Cutting | Very High (requires specialized tools, time-consuming) | Moderate (can be cut with standard tools) |

| Injury Potential | High (deep lacerations, entanglement) | Moderate (puncture wounds, scratches) |

| Typical Configuration | Concertina coils, flat wrap, welded mesh | Stranded wire, straight lines |

| Cost-Effectiveness (long-term) | High (initial investment higher, but greater longevity & security) | Moderate (lower initial cost, but less deterrent & shorter life) |

| Ideal Applications | High-security perimeters, critical infrastructure, correctional facilities, military bases | Agricultural fencing, low-security industrial areas, temporary barriers |

While barbed wire offers a basic level of deterrence, diamond razor wire provides a significantly higher level of security due to its sharper blades, stronger core wire, and concertina configuration, making it the preferred choice for environments where security breaches pose severe risks. For businesses seeking a truly robust and long-lasting barrier, investing in high-quality razor wire from reputable razor wire suppliers is a strategic decision.

Customized Solutions and Consultation Services

Recognizing that every security challenge is unique, leading razor wire suppliers offer comprehensive customization services to tailor diamond razor wire products to specific project requirements. These bespoke solutions ensure optimal performance, integration, and cost-efficiency.

- Material Customization: Options include various grades of galvanized steel (e.g., standard, heavy galvanized with up to 275 g/m² zinc coating) and different types of stainless steel (AISI 304, 316 for extreme corrosion resistance).

- Blade Profile Selection: Beyond the standard diamond blade, other blade types (e.g., CBT-65, BTO-30, BTO-28) are available to match specific deterrence levels and aesthetic considerations.

- Coil Diameter & Number of Clips: Custom coil diameters (e.g., 400mm, 500mm, 1000mm) and varying numbers of connecting clips (3, 5, 7, or 9 per turn) allow for adjustments in barrier density and effective extension length.

- Color and Coating Options: PVC or powder coating in various RAL colors can be applied for enhanced aesthetics, camouflaging, or additional environmental protection.

- Installation Accessories & Support: Providing specialized clips, brackets, and posts designed for seamless integration with existing fencing systems or for new installations. Expert consultation on optimal installation techniques is also available.

Our team of experienced engineers works closely with clients from conceptualization to deployment, conducting site assessments, recommending optimal configurations, and providing detailed technical drawings. This consultative approach ensures that the final solution meets not only the functional security requirements but also budgetary and logistical constraints.

Application Case Studies

Case Study 1: Border Security Enhancement Project

Client: National Border Patrol Agency

Challenge: Secure a 50 km stretch of rugged border terrain prone to illegal crossings and smuggling activities. The existing fence was easily breached, and the harsh desert environment demanded highly durable materials resistant to extreme temperatures and corrosion.

Solution: Deployment of heavy-duty, 900mm diameter diamond razor wire coils made from high-tensile, heavy-galvanized steel (275 g/m² zinc coating). The razor wire was installed on top of a 3-meter chain-link fence, forming a double concertina barrier. Special attention was paid to securing the coils to withstand high winds and tampering attempts.

Results: Within six months of installation, illegal crossings in the secured area decreased by over 80%. The robust physical barrier significantly increased the time and effort required for breaches, allowing patrol units to respond effectively. The heavy galvanization proved highly effective against the corrosive desert climate, showing no signs of degradation after 3 years.

Case Study 2: Data Center Perimeter Upgrade

Client: Global Cloud Services Provider

Challenge: Upgrade the perimeter security of a Tier 3 data center to meet increasingly stringent regulatory compliance for physical access control. The previous security fence, while robust, lacked a sufficient anti-climb deterrent. Downtime for installation needed to be minimized.

Solution: Flat-wrap diamond razor wire (CBT-65 blade type, 600mm height) was seamlessly integrated into the existing rigid mesh fence, extending its height and providing an immediate anti-climb solution without altering the fence's primary structure. Stainless steel AISI 304 was selected for maximum longevity and minimal maintenance, matching the high-tech aesthetic of the facility.

Results: The data center achieved enhanced compliance and a significant upgrade in its physical security posture. The flat-wrap design proved highly effective while maintaining a less aggressive visual profile compared to concertina coils. Installation was completed in phases over a weekend, causing no disruption to data center operations.

Frequently Asked Questions (FAQ)

Q: What is the primary difference between razor wire and barbed wire?

A: Razor wire features sharp, flat blades designed to cut and entangle, offering a superior deterrent and barrier against intrusion compared to the pointed barbs of traditional barbed wire, which primarily causes puncture wounds. Razor wire is also typically made with higher tensile strength steel.

Q: How long does diamond razor wire last?

A: The lifespan depends heavily on the material. Standard galvanized razor wire can last 7-15 years, while heavy-galvanized options extend to 15-20 years. Stainless steel (AISI 304 or 316) offers the longest service life, often exceeding 20-25 years, even in challenging environments.

Q: Is installation complicated for diamond razor wire?

A: While the material itself is dangerous and requires strict safety protocols, professional installation by experienced teams can be efficient. Manufacturers provide specific accessories (e.g., support brackets, tension wires) to facilitate secure and proper deployment.

Q: What are the typical lead times for large orders?

A: For standard products, lead times typically range from 2-4 weeks. For custom specifications or very large volumes, this may extend to 6-8 weeks, depending on material availability and production schedules. We advise clients to contact our sales team for precise lead time estimates based on their specific order.

Q: What warranty and after-sales support do you offer?

A: We offer a standard 5-year warranty on materials and workmanship for galvanized products, and up to 10 years for stainless steel products, covering manufacturing defects. Our after-sales support includes technical consultation, troubleshooting, and replacement parts, ensuring long-term product satisfaction and performance.

Conclusion

The strategic deployment of diamond razor wire represents a critical investment in robust perimeter security. Its technical advantages, derived from high-quality materials and meticulous manufacturing processes, provide an unparalleled level of deterrence and physical barrier integrity. For industries ranging from petrochemicals to defense, this advanced security solution offers long-term reliability, corrosion resistance, and adaptability to diverse environmental and operational demands. Partnering with experienced razor wire suppliers ensures access to expert guidance, customized solutions, and products that consistently meet stringent international standards, ultimately safeguarding assets, personnel, and operations.

References

- Global Market Insights. "Security Fencing Market Size By Product (Welded Mesh Fencing, Chain Link Fencing, Razor Wire, Barbed Wire), By Application (Commercial, Government, Industrial, Residential), Industry Analysis Report, Regional Outlook, Application Potential, Price Trends, Competitive Market Share & Forecast, 2021 – 2027."

- ASTM International. "ASTM A90/A90M-13: Standard Test Method for Weight of Coating on Iron and Steel Articles with Zinc or Zinc-Alloy Coatings."

- ASTM International. "ASTM B117-19: Standard Practice for Operating Salt Spray (Fog) Apparatus."

- International Organization for Standardization. "ISO 9001:2015: Quality management systems – Requirements."

- U.S. Department of Justice, National Institute of Justice. "NIJ Standard-0307.01: Perimeter Barrier Systems for Physical Security."

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025