Jul . 22, 2025 04:01 Back to list

Heavy-Duty Gabion Cages for Sale | Durable & Affordable

Hebei Yisizhe Manufacture (Group) Limited

Hebei Yisizhe Manufacture (Group) Limited has been a premier manufacturer of gabion boxes and wire mesh products for nearly two decades. With extensive experience in civil engineering and erosion control projects, we supply superior gabion solutions globally.

Premium Gabion Cages for Sale

The global demand for gabion cages for sale has increased by 22% in the last five years according to recent market analyses. As a leading gabion box supplier, Hebei Yisizhe remains at the forefront of this growth through continuous innovation in manufacturing techniques and engineering applications.

Hebei Yisizhe Gabion Box Solutions

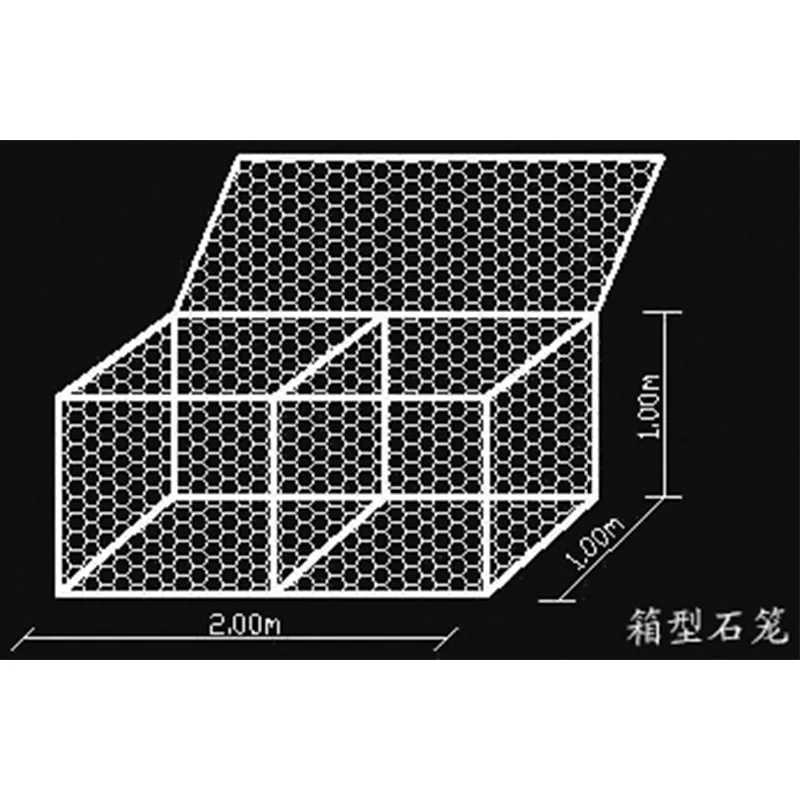

As a premier gabion box supplier, we specialize in manufacturing heavy-duty gabion boxes from galvanized steel wire. Our gabion cages for sale are engineered for:

- Erosion and flood control systems

- Retaining wall construction

- Bridge protection and riverbank stabilization

- Coastal defense against wave action

- Architectural and landscaping applications

We design and supply gabion boxes made of heavy hexagonal wire nettings. They are for the purpose of controlling and guiding water or floods, flood banks or guiding banks, preventing rock breaking, water and soil protection, bridge protection, strengthening the structure of soil, and protection engineering of seaside areas.

Explore Gabion Box Specifications

Gabion Cage Technical Specifications

Selecting the appropriate gabion cages for sale requires understanding key technical parameters. Our engineers have developed optimized specifications for various applications:

| Parameter | Standard | Heavy Duty | Marine Grade |

|---|---|---|---|

| Wire Diameter (mm) | 2.7 | 3.0 | 3.4 |

| Mesh Size (mm) | 80 × 100 | 60 × 80 | 80 × 100 |

| Galvanization (g/m²) | 215-265 | 245-285 | 290-320 |

| Tensile Strength (MPa) | 350-500 | 450-550 | 550-650 |

| Typical Box Dimensions (m) | 2×1×1 | 3×1×1 | 2×1×0.5 |

| Service Life (years) | 25-35 | 30-40 | 45-60 |

Gabion Performance Comparison

Applications of Gabion Solutions

Gabion cages for sale have evolved from simple erosion control devices to sophisticated engineering solutions. As a respected gabion box supplier, we've contributed to these innovative applications:

Global Gabion Market Application Share

Primary Applications

Modern gabion cages serve critical functions in:

- River Training Works: Bank stabilization in high-velocity flow areas

- Retaining Structures: Gravity walls up to 15 meters in height

- Coastal Defense: Breakwaters and groynes in marine environments

- Architectural Features: Sound barriers and decorative elements

- Erosion Control: Slope stabilization in vulnerable areas

Professional Gabion Technology FAQ

For marine environments, we recommend 3.4mm wire with high-grade galvanization (minimum 290 g/m²) or PVC coating for enhanced corrosion resistance. According to ASTM A975 specifications, marine-grade gabions should withstand salt spray testing for 4000+ hours without significant corrosion.

The EN 10223-3 standard requires tensile strength between 350-500 MPa for standard gabions. Heavy-duty applications demand 450-550 MPa. Our gabion boxes exceed these standards with reinforced selvedge wires at panel edges and double-twist hexagonal mesh construction for superior structural integrity.

Clay soils require wider foundations with geotextile separation layers to prevent pore pressure buildup. Sandy soils need deeper toe-in installations and potentially gabion mattresses as base reinforcement. Cohesive soils may require reduced batter angles and additional drainage behind structures. Engineering surveys should always precede gabion installation.

Our standard galvanized gabions provide 25-35 years of service. Heavy galvanization extends this to 40+ years. PVC-coated units in severe environments last 50+ years. Actual lifespan depends on water chemistry, impact exposure, and UV radiation levels. Regular inspections are recommended at 5-year intervals.

Optimal fill material should be 1.25-1.5 times the mesh opening size. For standard 80×100mm mesh, use 100-150mm diameter rocks. Angular stone provides superior interlock compared to rounded river stone. Avoid crushed material with high fines content which can accelerate deterioration through chemical leaching and pore pressure.

Key standards include EN 10223-3 (Europe), ASTM A975 (US), and AS 4671 (Australia). Testing regimes typically include tensile strength evaluation, zinc coating adherence checks, accelerated corrosion testing, and mesh deformation resistance measurements following established protocols in civil engineering materials certification.

Structural connections require high-tensile steel spiral binders or corrosion-resistant lacing wire with diameter matching the mesh wires. Adjacent baskets should be secured with every third mesh opening. Foundation anchoring typically employs earth anchors or driven steel pins at 1m intervals. For tall walls (>3m), we recommend internal tiebacks and stepped foundations.

Industry Research & Publications

"The evolution of gabion technology over the past decade has significantly enhanced erosion control effectiveness. Modern double-twist wire mesh designs with high-performance coatings demonstrate 40% greater hydraulic resistance than traditional designs."

International Conference on Soil Erosion, 2023"Long-term studies (15-year duration) of galvanized gabions in marine environments demonstrate that proper alloy composition combined with adequate coating thickness provides service life exceeding 50 years even in harsh coastal conditions."

Journal of Coastal Engineering, Volume 72, 2024"The market for sustainable erosion control solutions continues to shift toward engineered gabion systems, with industry growth projected at 7.8% CAGR through 2028. Innovation in specialized coating technologies represents the most significant product development segment."

Global Erosion Control Solutions Market Analysis, 2023"Comprehensive testing has established that correctly installed gabion retaining walls demonstrate structural stability equivalent to reinforced concrete alternatives at 30-40% lower cost, while offering superior environmental integration and drainage characteristics."

International Society of Geotechnical Engineering Technical Paper 1207, 2024-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025