Dec . 28, 2024 19:24 Back to list

Galvanized Roofing Nails for Durable and Reliable Roof Installations and Repairs

Understanding Galvanized Roofing Nails The Essential Choice for Roof Installation

When it comes to roofing projects, choosing the right materials is crucial for ensuring the longevity and durability of the roof. Among these materials, roofing nails play a vital role. Specifically, galvanized roofing nails have gained popularity in recent years due to their enhanced longevity and resistance to corrosion. In this article, we’ll delve into the benefits of using galvanized roofing nails, their types, applications, and why they should be a staple in any roofing installation.

What Are Galvanized Roofing Nails?

Galvanized roofing nails are metal fasteners that have undergone a galvanization process. This involves coating them with a layer of zinc to protect the steel from external elements. The galvanization process not only enhances the strength of the nail but also provides a barrier against rust and corrosion, which are common problems in roofing materials exposed to weather conditions.

Benefits of Using Galvanized Roofing Nails

1. Corrosion Resistance One of the primary advantages of galvanized roofing nails is their resistance to corrosion. Traditional steel nails can rust when exposed to moisture, leading to premature failure of the roofing system. Galvanized nails, with their protective coat, significantly mitigate this risk.

2. Durability Galvanized nails are designed to withstand the harshest weather conditions. Their durability is especially beneficial in regions prone to extreme temperatures, high humidity, or heavy rainfall.

3. Longevity Roofing systems are significant investments, and using quality materials is essential to ensuring their longevity. Galvanized roofing nails can extend the life of the roof by maintaining their integrity and reducing the need for frequent repairs or replacements.

4. Ease of Use Galvanized roofing nails come in various sizes and lengths, making them versatile for different roofing materials, including shingles, metal sheets, and tiles. They are also designed to drive easily into substrates, reducing installation time.

Types of Galvanized Roofing Nails

Galvanized roofing nails are available in two main types

1. Electro-galvanized These nails are coated with a zinc layer through an electrochemical process. They are typically less resistant to corrosion compared to hot-dipped nails, making them more suitable for indoor applications or areas with mild exposure to moisture.

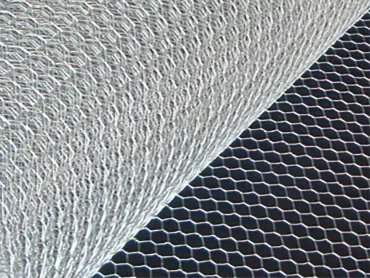

galv roofing nails

2. Hot-dipped galvanized This type involves dipping the nails in molten zinc, providing a thicker and more robust coating. Hot-dipped nails are ideal for outdoor use, particularly in climates that are prone to severe weather conditions.

Applications of Galvanized Roofing Nails

Galvanized roofing nails are used in various roofing projects, including residential houses, commercial buildings, and industrial facilities. They are compatible with a range of roofing materials, such as asphalt shingles, metal roofing, wood shakes, and tiles. In addition to roofing, these nails can also be used for siding and wall installations, offering a versatile solution for various construction needs.

Installation Tips for Galvanized Roofing Nails

To ensure the best results when using galvanized roofing nails, consider the following tips

1. Choose the Right Size Select a nail size that is appropriate for the roofing material and thickness being used. For standard asphalt shingles, a nail length of 1.5 inches is often recommended.

2. Proper Spacing Follow manufacturer guidelines for spacing between nails. Typically, nails should be placed at least 6 inches apart along the edges and 12 inches apart in the field of the roof.

3. Nail Positioning Ensure that nails penetrate through the roofing material and into the underlying structure (e.g., the sheathing) for secure fastening.

4. Avoid Overdriving When using a nail gun or hammer, be cautious not to overdrive the nails, as this can damage the roofing material and compromise the seal.

Conclusion

Incorporating galvanized roofing nails in your roofing project can make a significant difference in the durability and performance of the roof. Their resistance to corrosion, ease of use, and versatility make them an essential component for any roofing installation. By understanding the benefits and proper application of these nails, homeowners and contractors can ensure that their roofing systems provide reliable protection for years to come. Whether you’re embarking on a new construction project or repairing an existing roof, galvanized roofing nails are a wise investment in quality and longevity.

-

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025