Jan . 28, 2025 01:56 Back to list

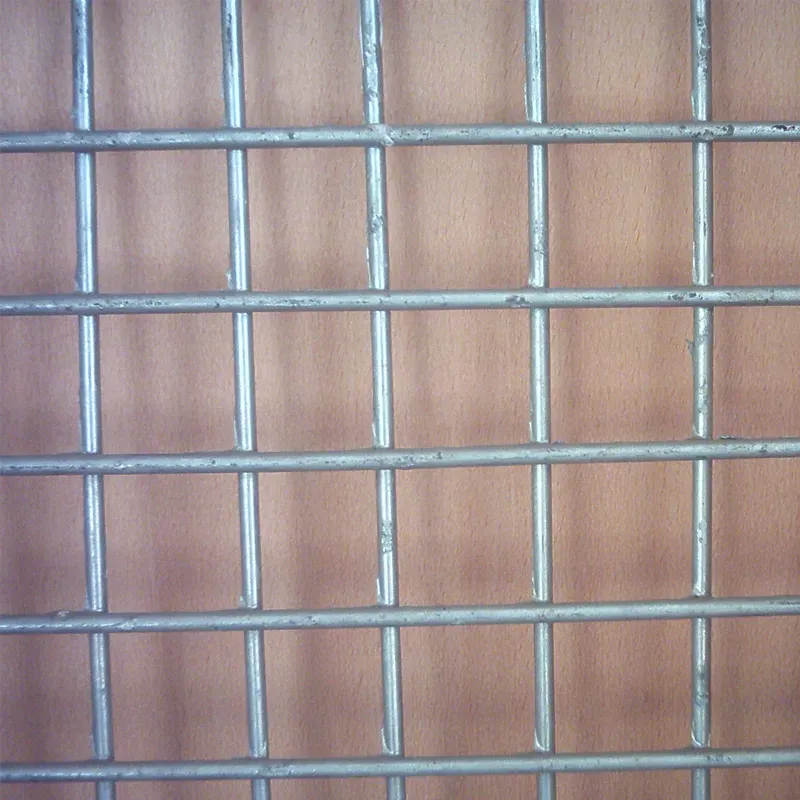

galvanized iron wire

Galvanized iron wire has become an indispensable material in various fields, appealing to industries with its remarkable properties of durability and flexibility. This versatile material is primarily used in construction, agriculture, and other industrial applications, proving its indispensable role across sectors.

Authoritative product knowledge is enhanced through in-depth research and collaboration with industry leaders. Recognizing that not all galvanized iron wires are created equal is fundamental. Variations in wire gauge, tensile strength, and level of galvanization cater to different requirements. For instance, a thin gauge wire with a thick layer of zinc may be perfect for outdoor fencing, while construction reinforcement might demand a heavier gauge with customized tensile properties. Consulting with producers and engineers ensures that the selection of galvanized iron wire meets the specific demands of each project, underscoring its authoritative application. The trustworthiness of galvanized iron wire as a product hinges on compliance with international standards, such as those set by the ASTM or EN. These standards guarantee that wires have undergone rigorous testing for consistency, strength, flexibility, and resistance to corrosive elements. Purchasers and project managers commit to these standards when sourcing materials, ensuring that they maintain high integrity in their operations. As a result, the credibility of using galvanized iron wire as a primary material gains significant reinforcement across its applications. In summary, galvanized iron wire exemplifies a harmonious blend of practical experience, specialized expertise, authoritative understanding, and trustworthy performance. Its application across various industries not only validates its essential role but also emphasizes the importance of informed material selection in achieving successful outcomes. Whether it is for securing structures, crafting dependable agricultural tools, or innovating in industrial practices, this material continues to inspire confidence and advanced utility among professionals and stakeholders alike.

Authoritative product knowledge is enhanced through in-depth research and collaboration with industry leaders. Recognizing that not all galvanized iron wires are created equal is fundamental. Variations in wire gauge, tensile strength, and level of galvanization cater to different requirements. For instance, a thin gauge wire with a thick layer of zinc may be perfect for outdoor fencing, while construction reinforcement might demand a heavier gauge with customized tensile properties. Consulting with producers and engineers ensures that the selection of galvanized iron wire meets the specific demands of each project, underscoring its authoritative application. The trustworthiness of galvanized iron wire as a product hinges on compliance with international standards, such as those set by the ASTM or EN. These standards guarantee that wires have undergone rigorous testing for consistency, strength, flexibility, and resistance to corrosive elements. Purchasers and project managers commit to these standards when sourcing materials, ensuring that they maintain high integrity in their operations. As a result, the credibility of using galvanized iron wire as a primary material gains significant reinforcement across its applications. In summary, galvanized iron wire exemplifies a harmonious blend of practical experience, specialized expertise, authoritative understanding, and trustworthy performance. Its application across various industries not only validates its essential role but also emphasizes the importance of informed material selection in achieving successful outcomes. Whether it is for securing structures, crafting dependable agricultural tools, or innovating in industrial practices, this material continues to inspire confidence and advanced utility among professionals and stakeholders alike.

Next:

Latest news

-

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025