Dec . 14, 2024 07:15 Back to list

Galvanized Iron Wire Applications and Benefits in Various Industries and Projects

The Versatility and Applications of Galvanized Iron Wire

Galvanized iron wire, a type of wire that has undergone galvanization to enhance its resistance to rust and corrosion, plays an indispensable role in various industries and applications. The process of galvanization involves coating the iron wire with a layer of zinc, which acts as a protective barrier against environmental elements. This article delves into the properties, manufacturing processes, and diverse applications of galvanized iron wire, highlighting its importance in today’s world.

Properties of Galvanized Iron Wire

One of the most notable properties of galvanized iron wire is its remarkable durability. The zinc coating not only protects the iron from moisture and air but also provides cathodic protection, meaning that if the coating is damaged, the underlying iron will still be safeguarded by the electrochemical properties of zinc. This makes galvanized iron wire an excellent choice for outdoor applications, where exposure to the elements can lead to rapid deterioration of unprotected metal.

Another important characteristic is its flexibility. Despite its strength, galvanized iron wire can be easily shaped, twisted, and woven, making it suitable for a wide range of uses. Additionally, the wire typically has a smooth surface, allowing for easy handling and installation. This combination of strength, flexibility, and corrosion resistance makes galvanized iron wire an indispensable material in many fields.

Manufacturing Process

The manufacturing of galvanized iron wire begins with the production of iron or steel wire, which can be drawn to various diameters based on intended use. Once the wire is produced, it undergoes the galvanization process. There are two primary methods for galvanization hot-dip galvanization and electro-galvanization.

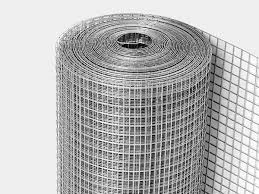

galvanized iron wire

In hot-dip galvanization, the wire is submerged in molten zinc, allowing for a thick coating to adhere to the surface. This method is known for producing heavy-duty galvanized wire that is often used in construction and fencing. In contrast, electro-galvanization involves the application of zinc using an electrochemical process, resulting in a thinner coating but often providing a smoother finish. This method is commonly used for applications requiring a more aesthetically pleasing appearance, such as in crafts and decorative projects.

Applications of Galvanized Iron Wire

Galvanized iron wire is renowned for its versatility and finds applications across various sectors. One of the most common uses is in construction. It is frequently employed as tie wire for reinforcing concrete structures, providing essential support and stability. Additionally, it is used in the creation of wire mesh for fences and barriers, which are crucial for enclosing properties and providing security.

In agriculture, galvanized iron wire is indispensable for creating trellises and supporting plants, ensuring that crops grow upright and are better exposed to sunlight. Farmers also use it to construct livestock enclosures, as it can withstand the wear and tear from animals, harsh weather conditions, and everyday use.

The crafting and decorative industries also benefit from galvanized iron wire. Artists and artisans appreciate its pliability and rustic appearance, incorporating it into sculptures, home decor, and various craft projects. More recently, its appeal in the DIY community has soared, with many individuals using it in innovative projects ranging from furniture to garden ornaments.

Conclusion

In conclusion, galvanized iron wire serves as a vital material in multiple domains due to its durability, flexibility, and resistance to corrosion. The manufacturing processes that yield this wire ensure that it meets the varied needs of industries ranging from construction and agriculture to arts and crafts. The ongoing demand for galvanized iron wire reflects its effectiveness and versatility, making it a fundamental component in building a resilient infrastructure and supporting our daily lives. As industries continue to evolve, the importance of galvanized iron wire remains, paving the way for future innovations and applications.

-

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025