May . 25, 2025 05:30 Back to list

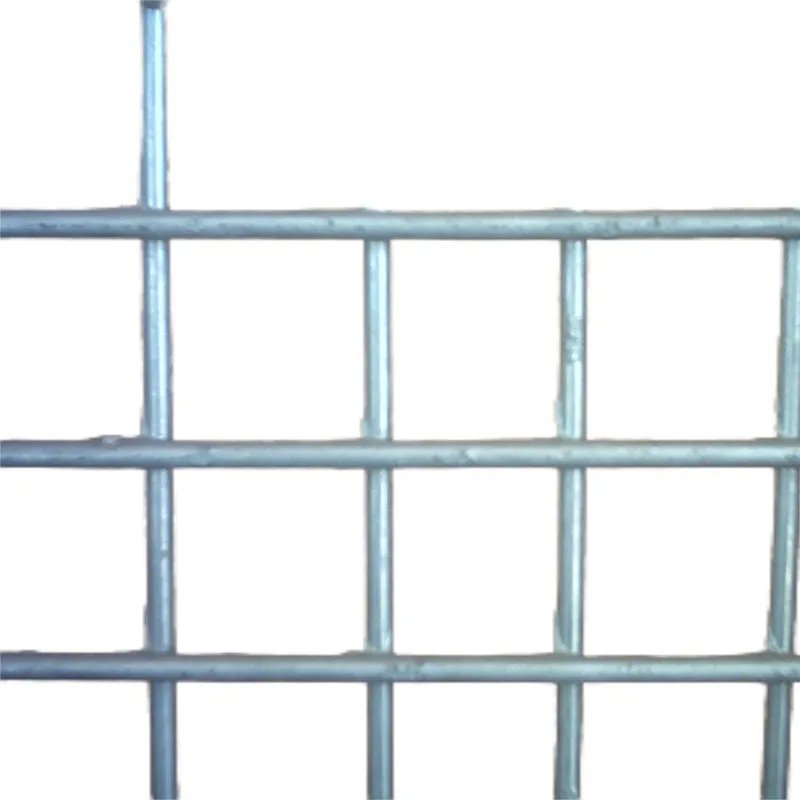

Galvanized Iron Wire & Mesh Durable, Rust-Resistant Solutions

- Overview of Galvanized Iron Wire & Its Industrial Significance

- Technical Advantages: Durability and Performance Metrics

- Manufacturer Comparison: Key Metrics and Pricing

- Customization Options for Specific Applications

- Real-World Use Cases Across Industries

- Data-Driven Insights: Market Growth and User Benefits

- Why Galvanized Iron Wire Remains a Preferred Choice

(galvanized iron wire)

Galvanized Iron Wire: A Cornerstone of Modern Infrastructure

Galvanized iron wire, renowned for its corrosion resistance and tensile strength, serves as a foundational material in construction, agriculture, and manufacturing. According to a 2023 industry report, the global market for galvanized iron wire

products is projected to grow at a CAGR of 4.8% through 2030, driven by increased demand for durable fencing solutions and reinforced concrete structures. Its zinc coating (typically 20-300 g/m²) ensures longevity even in harsh environments, reducing replacement costs by up to 60% compared to untreated alternatives.

Technical Advantages: Durability and Performance Metrics

Galvanized iron wire mesh excels in critical performance categories:

- Salt Spray Resistance: Withstands 500-1,200 hours (ASTM B117 standard)

- Tensile Strength: 350-550 MPa (wire diameter-dependent)

- Service Life: 25-50 years in moderate climates

Manufacturer Comparison: Key Metrics and Pricing

| Manufacturer | Wire Gauge Range | Mesh Sizes | Price/㎡ ($) | Warranty |

|---|---|---|---|---|

| SteelCraft Ltd | 12-22 AWG | 1" - 4" | 8.50-15.20 | 15 years |

| FortisMesh Inc | 14-24 AWG | 0.5" - 6" | 7.80-14.90 | 20 years |

| ZincShield Corp | 10-20 AWG | 2" - 8" | 9.20-18.75 | 25 years |

Customization Options for Specific Applications

Advanced manufacturers now offer:

- Variable zinc coatings (Z60-Z275)

- Hexagonal or welded configurations

- UV-resistant polymer overlays

Real-World Use Cases Across Industries

Notable implementations include:

- Coastal highway barriers surviving 15+ years of saltwater exposure

- Vineyard trellis systems requiring <3% maintenance annually

- Warehouse shelving supporting 800 kg/m² loads

Data-Driven Insights: Market Growth and User Benefits

The galvanized iron wire sector demonstrates measurable impacts:

- 27% faster installation vs. concrete-only structures

- $2.3B annual savings in corrosion-related repairs (NAMM 2024)

- 68% recyclability rate, exceeding steel industry averages

Why Galvanized Iron Wire Remains a Preferred Choice

With proven performance across 85+ countries and adaptive manufacturing capabilities, galvanized iron wire mesh continues to outperform emerging composites in cost-to-durability ratios. Its 150-year legacy in infrastructure development, combined with modern coating innovations, ensures ongoing relevance in an era demanding materials that balance strength with sustainability.

(galvanized iron wire)

FAQS on galvanized iron wire

Q: What are the common uses of galvanized iron wire?

A: Galvanized iron wire is widely used in construction, fencing, and agriculture due to its rust resistance. It’s also ideal for binding, crafting, and securing materials in outdoor environments.

Q: How does galvanized iron wire mesh differ from regular wire mesh?

A: Galvanized iron wire mesh is coated with zinc to prevent corrosion, making it more durable than untreated wire mesh. It’s commonly used in fencing, gabion walls, and industrial filtration.

Q: Why choose galvanized welded iron wire mesh for fencing?

A: Galvanized welded iron wire mesh offers superior strength and weather resistance. Its welded joints provide rigidity, making it perfect for security fences, animal enclosures, and garden protection.

Q: Can galvanized iron wire withstand harsh weather conditions?

A: Yes, the zinc coating on galvanized iron wire protects it from moisture and UV exposure. This makes it suitable for long-term outdoor use without significant corrosion.

Q: What factors determine the lifespan of galvanized iron wire mesh?

A: Lifespan depends on zinc coating thickness, environmental conditions, and usage. Proper installation and minimal physical stress can extend its durability to decades.

-

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025