Aug . 14, 2025 03:00 Back to list

Durable Field Fencing for Horses | Safe Pasture Fence

Strategic Selection of Field Fencing for Horses: Ensuring Safety and Durability

In modern equestrian and agricultural management, the integrity of perimeter control is paramount. Selecting the right field fencing for horses is a critical decision that impacts not only the safety and well-being of livestock but also the operational efficiency and long-term cost-effectiveness for farm owners and facility managers. Industry trends indicate a growing demand for fencing solutions that offer superior strength, minimal maintenance, and extended service life, driven by rising material costs and labor scarcity. This necessitates a detailed understanding of the technical specifications, manufacturing processes, and application advantages of high-performance field fence systems. Our focus is on providing robust, engineered solutions that meet stringent industry standards and address the unique challenges of livestock containment.

The evolution of field and fence technology has led to innovations in materials and knot configurations, significantly enhancing the reliability and safety aspects crucial for equine environments. Unlike conventional barbed wire or basic woven wire, specialized fence for field applications tailored for horses prioritize safety features such as smooth surfaces and flexible designs to prevent injury, alongside robust construction to withstand pressure from large animals. This article delves into the intricate details of manufacturing, material science, technical parameters, and strategic implementation, providing B2B decision-makers with the essential knowledge to make informed procurement choices.

Advanced Manufacturing Processes and Material Excellence for Field Fence

The production of high-quality field fencing for horses involves a sophisticated multi-stage manufacturing process designed to ensure unparalleled durability and performance. Primarily, the core material consists of high-tensile steel wire, selected for its superior strength-to-weight ratio and resilience. This steel undergoes a rigorous hot-dip galvanization process, where the wire is immersed in molten zinc. This process creates a metallurgical bond, forming a protective zinc coating that significantly enhances corrosion resistance and extends the product's lifespan, even in harsh weather conditions or environments with high humidity and chemical exposure. This protective layer is crucial for applications where the fence is exposed to animal waste and various environmental stressors.

Figure 1: Illustration of a typical field fence weaving machine, highlighting the precision required for consistent mesh formation.

Following galvanization, the wires are fed into advanced weaving or knotting machines. Two primary knot types dominate the market for field fence: the hinged joint and the fixed knot. The hinged joint offers flexibility, allowing the fence to conform to uneven terrain and absorb impact from animals without permanent deformation. The fixed knot, conversely, provides superior rigidity and structural integrity, making it ideal for high-pressure applications where minimal deflection is desired. This type of knot creates a virtually unbreakable bond between the horizontal and vertical wires, preventing slippage and maintaining consistent mesh spacing. All manufacturing steps adhere to international standards such as ASTM A641 (Standard Specification for Zinc-Coated (Galvanized) Carbon Steel Wire) and ASTM A116 (Standard Specification for Metallic-Coated Carbon Steel Barbed Wire and Barbed Tape) to ensure product quality and performance. The typical service life of our galvanized field fence exceeds 20-30 years, significantly reducing the total cost of ownership for end-users in agriculture, livestock management, and equestrian industries.

Technical Specifications and Performance Metrics

Understanding the technical parameters of field fencing for horses is crucial for specifying the correct product for a given application. Key specifications include wire gauge, fence height, length per roll, and the spacing of horizontal (line) and vertical (stay) wires. The graduated mesh design, common in horse fencing, features smaller openings at the bottom to prevent foals or smaller animals from passing through, gradually increasing in size towards the top. This design minimizes entanglement risks while maximizing material efficiency.

| Parameter | Description / Typical Range | Relevance for Horse Fencing |

|---|---|---|

| Wire Gauge (Ga.) | 10 ga. to 14.5 ga. (10 Ga. being thicker) | Lower gauge (thicker wire) provides greater strength and durability, essential for containing strong animals like horses. Common for line wires: 12.5 Ga. |

| Fence Height | 1.2m (47 in.) to 1.8m (72 in.) | Adequate height prevents horses from jumping over. Minimum 1.5m (60 in.) is often recommended for average-sized horses. |

| Roll Length | 50m (165 ft) to 100m (330 ft) | Standard lengths for efficient installation over large perimeters. |

| Line Wire Spacing (vertical) | Graduated; typically 7.5cm (3 in.) at bottom, increasing to 20cm (8 in.) at top. | Prevents small animals/foals from slipping through, while providing adequate visibility and material efficiency higher up. |

| Stay Wire Spacing (horizontal) | 15cm (6 in.), 30cm (12 in.), or 60cm (24 in.) | Determines the rigidity and impact resistance of the fence. Closer spacing offers greater stability and reduces risk of entanglement. |

| Knot Type | Hinged Joint, Fixed Knot | Hinged offers flexibility for terrain, Fixed offers superior rigidity and strength, ideal for high-pressure horse containment. |

| Coating Type | Hot-dip Galvanized (Class 1, Class 3) | Class 3 galvanization provides the thickest zinc coating, ensuring maximum corrosion resistance and a longer lifespan, crucial for outdoor equestrian use. |

These specifications collectively determine the performance characteristics of the field fencing for horses. For instance, a heavier gauge wire combined with a fixed knot design and graduated mesh offers superior containment capabilities and resistance to impacts, reducing maintenance and replacement costs over its operational lifetime. Our products are rigorously tested to ensure they meet or exceed these industry benchmarks, providing peace of mind for B2B clients.

Application Scenarios and Technical Advantages

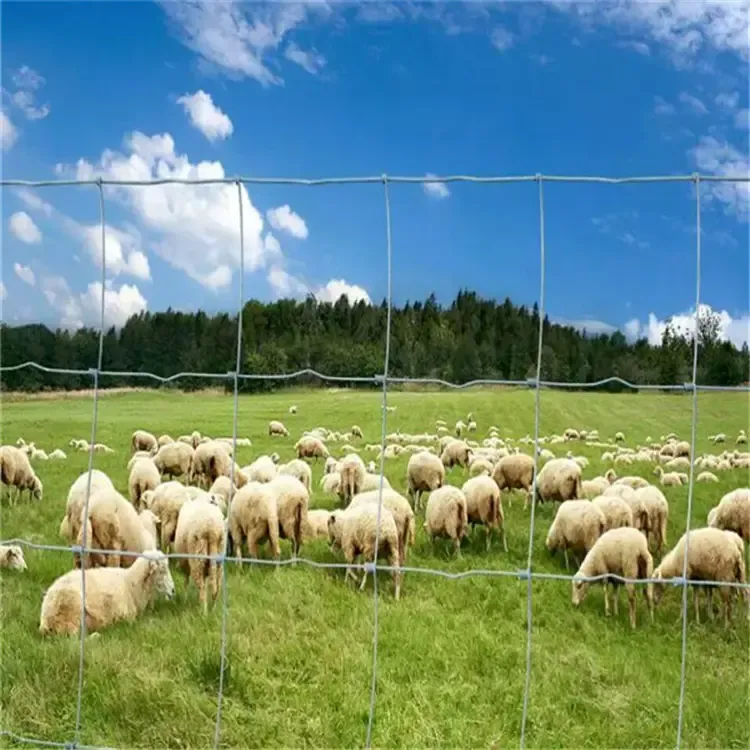

Field fencing for horses is indispensable across a range of applications within the agricultural and equestrian sectors. Its primary use includes defining pastured areas, creating secure paddocks, establishing rotational grazing systems, and segmenting large properties. This type of fence for field is also highly effective for property line demarcation, especially in rural settings where aesthetics and long-term durability are important. Its robust construction makes it suitable for containing various types of livestock beyond horses, including cattle, sheep, and goats, although specific configurations may vary.

Figure 2: A secure paddock utilizing field fencing, demonstrating its effectiveness in horse containment.

The technical advantages of choosing specialized field fencing for horses are manifold. Firstly, the high-tensile wire, combined with appropriate knotting, offers superior impact absorption. This means the fence can flex under pressure from a horse leaning or running into it, then return to its original shape, minimizing the risk of injury to the animal and damage to the fence. Secondly, the heavy galvanization provides exceptional anti-corrosion properties, significantly extending the fence's functional life and reducing the frequency of costly repairs or replacements. This longevity translates into substantial long-term savings compared to less durable fencing options. Lastly, the graduated mesh design offers enhanced safety for horses by preventing hoof entanglement, a common concern with fences that have uniform, large openings. This feature makes it a safer and more humane choice for equine enclosures.

Customized Solutions and Manufacturer Expertise

Recognizing that every farm or equestrian facility has unique requirements, customization is a key aspect of our offering for field fencing for horses. We provide tailored solutions in terms of fence height, wire gauge, and specific mesh configurations to meet diverse containment needs and environmental conditions. For instance, properties located in areas prone to heavy snowfall may benefit from specific wire gauges and knot types that offer greater resistance to deformation. Similarly, fencing designed for broodmares and foals will prioritize smaller bottom mesh openings for enhanced safety.

Figure 3: Customized field fence showcasing different specifications for targeted applications.

Choosing a reputable manufacturer is paramount when investing in field and fence solutions. A leading manufacturer is characterized by adherence to international quality management systems such as ISO 9001, rigorous quality control at every production stage, and a commitment to material traceability. For over 15 years, our company has specialized in wire mesh products, building a reputation for reliability and technical excellence. We partner with agricultural cooperatives, large-scale livestock operations, and equestrian centers, providing solutions that integrate seamlessly into their infrastructure. Our engineering team provides comprehensive consultation, from initial site assessment to installation guidance, ensuring that the selected field fencing for horses solution optimizes both performance and cost-efficiency. Our commitment to sustainability is also reflected in our production processes, which aim to minimize waste and energy consumption.

Trustworthiness, Warranty, and Client Support

At Yiszhe Wire Mesh, trustworthiness is built on transparent processes and unwavering support. Our field fencing for horses products are backed by a comprehensive 20-year limited warranty, covering defects in materials and workmanship, particularly against premature corrosion under normal usage conditions. This warranty underscores our confidence in the longevity and quality of our galvanization and wire integrity. Our standard delivery cycle typically ranges from 15 to 30 business days, depending on order volume and customization requirements. For urgent projects, expedited shipping options are available. We maintain a dedicated customer support team accessible via phone and email, providing technical assistance, installation advice, and post-sales service to ensure maximum client satisfaction.

Frequently Asked Questions (FAQ)

- Q: What makes your field fencing for horses superior to standard farm fencing?

A: Our fencing utilizes high-tensile wire and specialized knots (hinged or fixed) designed to absorb impact and prevent injury, unlike standard farm fences which may not offer the same level of safety and durability for equine applications. The graduated mesh also prevents entanglement. - Q: Can the fence be installed on uneven terrain?

A: Yes, our field fence, particularly with the hinged joint knot, is designed to flex and conform to varying terrain, minimizing gaps and maximizing containment effectiveness without compromising structural integrity. - Q: What is the expected lifespan of your galvanized fence for field?

A: With Class 3 hot-dip galvanization, our field fencing typically boasts a service life exceeding 20-30 years, significantly reducing maintenance and replacement costs over time. - Q: Do you offer installation services or guidance?

A: While we primarily supply the fencing materials, our technical support team provides comprehensive installation guidance, best practice recommendations, and can connect clients with certified installers in their region. - Q: How do I choose the correct height and wire gauge for my specific needs?

A: Our experts offer consultation to assess your specific requirements, considering horse breed, local regulations, and environmental factors, to recommend the optimal fence height and wire gauge for maximum safety and efficiency.

Authoritative References

- American Society for Testing and Materials (ASTM) International. ASTM A641/A641M-09: Standard Specification for Zinc-Coated (Galvanized) Carbon Steel Wire.

- American Society for Testing and Materials (ASTM) International. ASTM A116-00(2005): Standard Specification for Metallic-Coated Carbon Steel Barbed Wire and Barbed Tape.

- International Organization for Standardization (ISO). ISO 9001:2015 Quality Management Systems – Requirements.

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025