Aug . 13, 2025 03:20 Back to list

Gabion Cages For Sale: Durable & Affordable Gabion Boxes

Understanding the Modern Gabion Industry Landscape

The global market for civil engineering solutions is witnessing a significant surge in demand for durable and eco-friendly erosion control and structural retention systems. Among these, gabion structures have emerged as a cornerstone, offering unparalleled flexibility and sustainability for diverse applications. The increasing frequency of extreme weather events and the imperative for resilient infrastructure are primary drivers for the escalating need for gabion cages for sale. Industry trends indicate a sustained growth trajectory, particularly in developing economies, propelled by large-scale infrastructure projects such as highway construction, river training, and urban development. Furthermore, the emphasis on green infrastructure and sustainable construction practices by governmental bodies worldwide is solidifying the position of gabions as a preferred solution.

Technological advancements in wire mesh manufacturing and coating processes have significantly enhanced the performance and longevity of the modern gabion box. This evolution allows for tailored solutions addressing specific environmental and structural challenges, moving beyond traditional applications to include innovative architectural and landscape designs. The demand for reliable gabion box supplier solutions is critical, as project success hinges on the quality, dimensional accuracy, and material integrity of the supplied gabion units. As a versatile and adaptive engineering material, gabions are increasingly specified in projects requiring permeable, flexible, and robust structures, aligning with contemporary engineering principles focused on minimizing environmental impact while maximizing structural stability.

The Advanced Manufacturing Process of Gabion Cages

The production of high-quality gabion cages for sale involves a meticulous manufacturing process, ensuring durability and performance under various environmental stresses. The primary material is typically low-carbon steel wire, conforming to international standards such as ASTM A641 (Standard Specification for Zinc-Coated (Galvanized) Carbon Steel Wire) or EN 10218-2 (Steel wire and wire products - General technical delivery conditions for wire). This wire undergoes a precision double-twist or welded mesh formation process, crucial for imparting structural integrity and preventing unraveling in case of localized wire breaks. The double-twist hexagonal mesh, a common configuration, offers exceptional flexibility and resistance to deformation, allowing the structure to settle without fracturing under dynamic loads.

Following the mesh weaving or welding, the wire is subjected to various protective coatings to enhance corrosion resistance, a critical factor for the long-term viability of a gabion box in exposed environments. Standard coatings include heavy zinc galvanization (Class A, B, or C per ASTM A641), Galfan® (Zinc-5% Aluminum-Mischmetal alloy), or PVC coating applied over a galvanized or Galfan® base. Each coating offers distinct advantages; for instance, Galfan® provides superior corrosion protection compared to standard zinc, while PVC coating is ideal for highly corrosive environments such as marine or chemical waste areas. Quality control is paramount throughout the manufacturing cycle, with rigorous testing for wire tensile strength (typically 380-550 N/mm²), elongation, and coating thickness, ensuring compliance with ISO 9001 and other relevant industry specifications. The estimated service life for heavily galvanized gabions can exceed 25 years, while PVC-coated units can last over 50 years, showcasing their robust design and material resilience.

Technical Parameters and Specifications of Gabion Cages

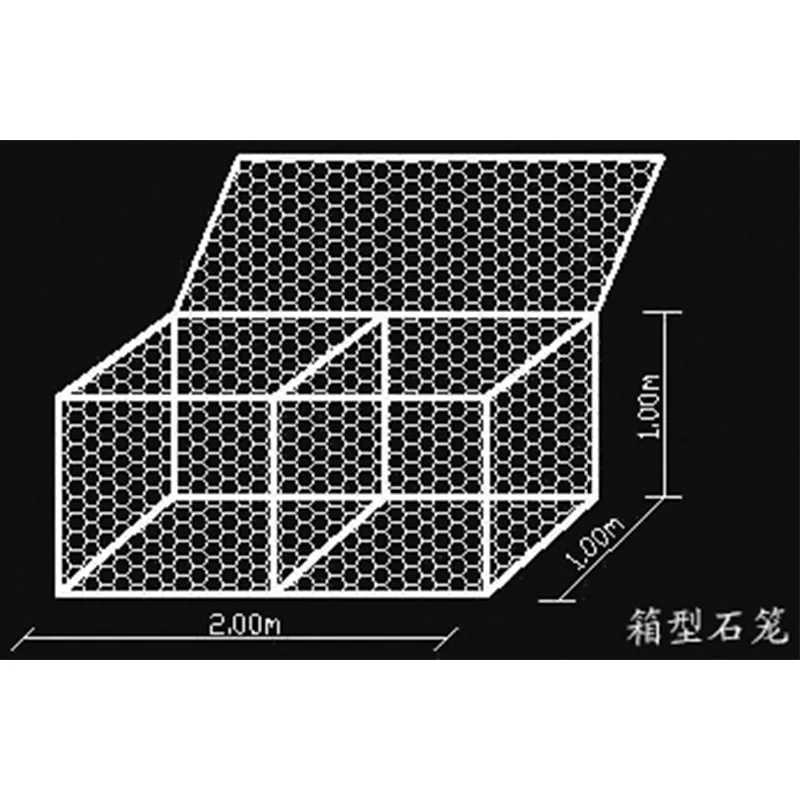

Selecting the appropriate gabion box requires a thorough understanding of its technical specifications. Key parameters include wire diameter, mesh opening size, box dimensions, and coating type. Wire diameters typically range from 2.2 mm to 4.0 mm for gabion mesh, with selvedge (edge) wires often thicker to provide additional structural rigidity. Mesh openings, commonly hexagonal, can vary from 60x80 mm to 100x120 mm, influencing the required fill material size and the structure's permeability. The choice of mesh size depends on the desired aesthetics, the size of the rock fill, and the hydraulic conditions for water-related applications.

For those seeking gabion cages for sale, standard dimensions are widely available, though custom sizes are routinely offered by specialized suppliers. Common dimensions for gabion boxes are lengths of 1m to 4m, widths of 1m, and heights ranging from 0.5m to 1m. Gabion mattresses, often used for erosion control and channel lining, typically have heights of 0.17m to 0.3m. The material specifications, including tensile strength and zinc coating mass (e.g., minimum 240 g/m² for heavy galvanized wire), are rigorously tested to meet or exceed industry standards like ASTM A975 (Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses (Metallic-Coated Steel Wire or Metallic-Coated Steel Wire With PVC Coating) for Civil Engineering Purposes). These precise specifications ensure that the final gabion structure performs as engineered, providing reliable and long-lasting erosion control and earth retention solutions.

Typical Gabion Box Specifications

| Parameter | Common Range | Standard | Notes |

|---|---|---|---|

| Wire Diameter (Mesh) | 2.0mm - 4.0mm | ASTM A975, EN 10223-3 | Heavier gauges for more demanding applications. |

| Wire Diameter (Selvedge) | 3.0mm - 5.0mm | ASTM A975, EN 10223-3 | Typically 0.5mm to 1.0mm thicker than mesh wire. |

| Mesh Opening Size | 60x80mm, 80x100mm, 100x120mm | ASTM A975, EN 10223-3 | Hexagonal woven mesh. |

| Standard Box Dimensions (L x W x H) | 2x1x1m, 3x1x1m, 4x1x1m, 2x1x0.5m, etc. | Customizable | Modular units for flexible construction. |

| Coating Type | Heavy Galvanized, Galfan (Zn-5%Al), PVC Coated | ASTM A641, ASTM A975 | Selection based on environmental corrosivity. |

| Tensile Strength | 380-550 N/mm² | ASTM A975, EN 10223-3 | Wire strength before mesh formation. |

Versatile Applications and Technical Advantages of Gabion Systems

The inherent flexibility, permeability, and environmental compatibility of gabion box systems make them ideal for a broad spectrum of engineering and architectural applications. In civil engineering, they are extensively used for retaining walls, providing a mass gravity structure that adapts well to differential ground settlement without fracturing, unlike rigid concrete structures. For hydraulic engineering, such as river bank protection, channel linings, and dam spillways, gabions and gabion mattresses are indispensable. Their permeability allows for the dissipation of hydrostatic pressure, preventing uplift and ensuring stability while promoting natural drainage and vegetation growth. This makes them a superior choice for erosion control and sediment management, particularly in regions prone to heavy rainfall or flash floods.

Beyond traditional uses, gabions are increasingly employed in specialized industrial contexts. For instance, in sectors like petrochemical and metallurgy, where infrastructure integrity is paramount, gabion walls can provide critical slope stabilization around processing units, storage tanks, and transportation corridors, effectively managing potential erosion from chemical runoff or heavy equipment vibrations. Their robust construction and corrosion-resistant coatings make them suitable for challenging industrial environments, contributing to site safety and longevity. Additionally, their inherent sound-absorbing qualities make them viable for noise barrier applications along highways or industrial perimeters, effectively mitigating acoustic pollution. For any large-scale project requiring durable, low-maintenance, and adaptable structures, evaluating gabion cages for sale from a reputable gabion box supplier is a crucial step in sustainable design and construction.

Choosing Your Gabion Box Supplier: Comparison and Customization

When sourcing gabion cages for sale, the selection of a gabion box supplier is a critical decision that impacts project timelines, budget, and long-term performance. Key factors to consider include the supplier's manufacturing capabilities, adherence to international quality standards, production capacity, and flexibility in offering customized solutions. A reputable supplier will not only provide products meeting ISO 9001 certification but also offer transparent data on material traceability, coating thickness, and tensile strength test results. Their expertise should extend to recommending optimal gabion types and specifications based on project-specific environmental conditions and structural requirements, ensuring the chosen solution delivers maximum value and longevity.

Customization options are often vital for complex or unique projects. While standard gabion box dimensions cover most needs, specific site constraints might necessitate custom lengths, widths, or heights, or even specialized mesh configurations. A competent supplier should be able to accommodate these bespoke requirements efficiently, offering pre-assembled or flat-packed units depending on logistical preferences and installation efficiency. Furthermore, evaluate their supply chain resilience and delivery lead times, especially for large-volume orders, to prevent project delays. Collaborating with an experienced supplier who offers comprehensive technical support, from initial design consultation to post-delivery assistance, can significantly streamline project execution and guarantee the structural integrity of the gabion system for decades to come.

Case Studies and Real-World Applications

Real-world applications powerfully demonstrate the efficacy and versatility of gabion cages for sale. Consider a major river training project in Southeast Asia, where extensive sections of riverbanks were stabilized using large-scale gabion box retaining walls and revetment mattresses. The permeable nature of the gabions allowed the river's flow to pass through, reducing hydrostatic pressure behind the walls and preventing scour, while simultaneously encouraging the growth of riparian vegetation within the rock fill, creating a resilient and eco-friendly habitat. This project successfully mitigated severe erosion, protected agricultural lands, and ensured navigational safety, showcasing gabions' long-term durability and low maintenance requirements.

Another compelling example involves a recent landslide remediation project in a mountainous region, where a flexible gabion wall was constructed to stabilize a critical roadway embankment. Unlike rigid concrete, the gabion structure could absorb and accommodate slight ground movements inherent to the geologically active area without cracking. This flexibility was crucial in preventing further slope failure and ensuring the continued integrity of the transportation infrastructure. These cases underscore the technical advantages of gabions: their adaptability to uneven foundations, superior drainage capabilities, and environmental benefits, making them a preferred engineering solution for challenging terrain and dynamic environments. The successful implementation of these projects highlights the importance of partnering with a knowledgeable gabion box supplier who can provide not just materials, but also technical insights and support.

Frequently Asked Questions (FAQ) about Gabion Boxes

Q1: What is the typical lifespan of a Gabion Box?

A1: The lifespan of a gabion box largely depends on the wire coating. Heavily galvanized gabions typically last 25-50 years in non-aggressive environments. For more corrosive environments (e.g., coastal, acidic soils), PVC-coated gabions, which offer an additional layer of protection, can last over 50 years, often exceeding 75 years, as indicated by long-term performance data from various civil engineering projects globally.

Q2: Are gabions environmentally friendly?

A2: Yes, gabions are considered highly environmentally friendly. They use locally sourced rock fill, minimizing transportation costs and carbon footprint. Their permeable nature promotes natural drainage and can support vegetation growth within the structure, fostering biodiversity and creating ecological habitats. This "green" aspect is a significant advantage for those looking for gabion cages for sale that align with sustainable construction practices.

Q3: What are the primary advantages of gabions over rigid structures like concrete?

A3: Gabions offer superior flexibility, allowing them to deform and settle without fracturing, which is critical in unstable ground conditions. They are permeable, eliminating hydrostatic pressure buildup, which can damage rigid structures. Installation is often simpler and faster, requiring less specialized equipment. Furthermore, gabions are more cost-effective in terms of material and construction, and their aesthetic can blend more naturally with the landscape, unlike stark concrete walls.

Q4: What is the typical delivery period for a large order of gabion cages?

A4: Delivery periods for gabion cages for sale depend on the order volume, customization requirements, and the gabion box supplier's production schedule. For standard large orders, lead times typically range from 2 to 4 weeks from order confirmation. For highly customized or exceptionally large projects, it's advisable to consult directly with the supplier for an accurate timeline. Expedited options might be available for urgent requirements.

Q5: What kind of warranty do you offer on your Gabion Boxes?

A5: As a commitment to quality and customer trust, we provide comprehensive warranties on our Gabion Box products. For heavily galvanized gabions, a typical warranty period against manufacturing defects and premature corrosion is 5 to 10 years. For PVC-coated gabions, this extends to 10 to 20 years. Specific warranty details are provided with each quotation and are in line with industry best practices, ensuring peace of mind for our clients regarding the long-term performance and durability of our gabion solutions.

Authoritative References

- ASTM International. (2020). ASTM A975/A975M-20: Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses (Metallic-Coated Steel Wire or Metallic-Coated Steel Wire With PVC Coating) for Civil Engineering Purposes.

- International Organization for Standardization. (2015). ISO 9001:2015 - Quality management systems — Requirements.

- Maccaferri Gabions. (Various publications on gabion technology and applications).

- U.S. Department of Transportation, Federal Highway Administration. (Various publications on stream bank protection and erosion control).

- European Committee for Standardization. (2012). EN 10223-3: Steel wire and wire products - Steel wire for fences and netting - Part 3: Hexagonal steel netting for civil engineering purposes.

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025