Aug . 14, 2024 04:14 Back to list

Durable Corrosion-Resistant Welded Wire Mesh for Various Industrial and Agricultural Applications

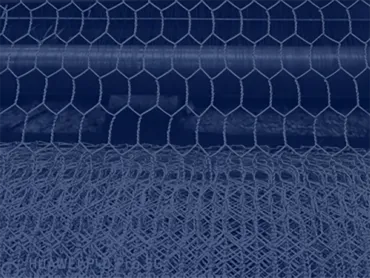

Galvanized Welded Wire Mesh An Essential Material for Various Applications

Galvanized welded wire mesh is a form of product that consists of wires welded together to form a grid, which is then coated with a layer of zinc to protect against corrosion. This unique combination of materials and processes makes galvanized welded wire mesh an invaluable resource in a variety of applications across different industries. From agriculture to construction, its durability, strength, and versatility make it an essential component for many projects.

One of the primary advantages of galvanized welded wire mesh is its resistance to rust and corrosion. The galvanization process involves dipping the wire into molten zinc, creating a protective barrier that prevents moisture and chemicals from reaching the underlying steel. This characteristic is particularly beneficial for outdoor applications, where exposure to the elements can lead to rapid deterioration of unprotected materials. By using galvanized wire mesh, one can significantly extend the lifespan of installations, reducing the need for frequent replacements and maintenance.

In the agricultural sector, galvanized welded wire mesh is widely used for livestock fencing and enclosures

. Farmers employ this material to create secure barriers for animals, protecting them from external threats and preventing them from wandering off. The mesh is designed to withstand harsh environmental conditions, ensuring that it remains functional for years while maintaining the safety of the livestock within. Additionally, it can be used to construct trellises for climbing plants, providing stability and support for vines to flourish.galvanized welded wire mesh

In the construction industry, galvanized welded wire mesh serves numerous purposes. It is commonly utilized in concrete reinforcement, where it adds strength and stability to the structure. The mesh is laid within concrete slabs, ensuring that the weight is evenly distributed and reducing the risk of cracking. Furthermore, it is often used as a partition material or screening, enabling the creation of protective barriers and enclosures in various settings. Its lightweight nature combined with high tensile strength makes it an ideal choice for a wide range of construction applications.

Another significant application of galvanized welded wire mesh is in the realm of industrial settings. Factories and warehouses often require enclosures for equipment or materials to improve safety and organization. The robust nature of the wire mesh ensures that a secure environment is maintained, minimizing the risk of accidents and mishaps. It can also be utilized as part of storage solutions, such as separation panels, shelving supports, or custom racks, enhancing the efficiency of space utilization.

Beyond these functional applications, galvanized welded wire mesh can also be employed in aesthetic designs and landscaping projects. Gardeners and landscape architects often use it to create stylish fences or decorative screens, combining practicality with visual appeal. Its versatility allows for creative designs that contribute to the overall aesthetic of outdoor spaces while also serving crucial protective roles.

In conclusion, galvanized welded wire mesh is a highly versatile and durable material with a wide range of applications across various industries. From agriculture and construction to industrial settings and landscaping, its resistance to corrosion, strength, and adaptability make it an essential choice for many projects. As the importance of sustainable and long-lasting materials continues to grow, galvanized welded wire mesh stands out as a reliable solution that meets diverse needs, ensuring that projects are completed efficiently and effectively. Whether for reinforcing structures or creating secure enclosures, its impact is felt across numerous domains, making it a staple in modern manufacturing and construction practices.

-

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025