Nov . 08, 2024 15:47 Back to list

diamond mesh manufacturer

The Emergence of Diamond Mesh Manufacturers A Comprehensive Overview

In the contemporary world of manufacturing and construction, mesh products have gained significant importance due to their versatile applications and benefits. Among the various types of mesh available, diamond mesh is notably recognized for its unique shape, strength, and aesthetic appeal. As such, the role of diamond mesh manufacturers has become increasingly crucial, providing high-quality products that cater to a wide range of industries.

Understanding Diamond Mesh

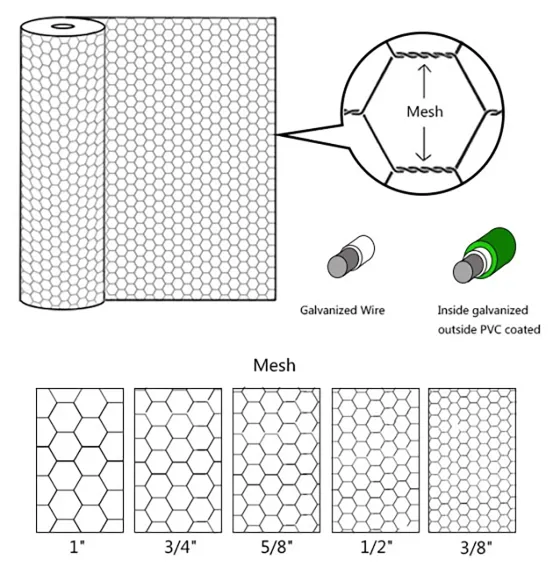

Diamond mesh, characterized by its diamond-shaped openings, is primarily crafted from materials such as stainless steel, aluminum, or galvanized steel. This mesh type is favored for its strength-to-weight ratio, making it ideal for various applications including fencing, architectural designs, and industrial use. The diamond shape offers not only structural integrity but also an enhanced visual effect, which makes it a preferred choice in both residential and commercial projects.

Applications of Diamond Mesh

The applications of diamond mesh are diverse, reflecting its adaptability to different environments and needs. In the construction industry, it is commonly used for security fencing, providing a reliable barrier while allowing visibility, which is essential in many settings. Furthermore, the mesh is often employed in industrial environments for safety barriers, walkways, and equipment protection.

In architecture, diamond mesh is increasingly used as a decorative element. It can be integrated into building facades, windows, and railings, contributing to an appealing aesthetic without compromising safety. Additionally, diamond mesh is utilized in landscaping to create visually interesting garden features or as trellises for climbing plants.

The Role of Diamond Mesh Manufacturers

diamond mesh manufacturer

Diamond mesh manufacturers play a vital role in supplying these essential products. They ensure that the mesh produced meets the highest quality standards, which is critical given the various applications in which diamond mesh is utilized. The manufacturing process involves welding or weaving wires to form the diamond shape, followed by surface treatments to enhance durability and resistance to corrosion.

Manufacturers must also adapt to the latest technological advancements. Innovations such as automated production lines and improved welding techniques allow manufacturers to produce diamond mesh more efficiently and with higher precision. Additionally, the incorporation of quality control measures ensures that the final product is free from defects and able to withstand the rigors of its intended environment.

Sustainability Considerations

As environmental awareness grows, many diamond mesh manufacturers are also focusing on sustainable practices. Utilizing recycled materials in the production of the mesh not only reduces waste but also lowers the carbon footprint associated with manufacturing. Additionally, manufacturers are increasingly adopting eco-friendly coatings and treatments that minimize environmental impact while maintaining product longevity.

Customer Focus and Customization

Another significant aspect of diamond mesh manufacturers is their commitment to customer satisfaction. Many manufacturers offer customized solutions tailored to specific client needs. This could involve varying the size and shape of the diamond openings, altering the gauge of the wire, or providing additional surface treatments to enhance performance in particular applications. Such customization strengthens the relationship between manufacturers and their clients, ensuring that the final product perfectly aligns with expectations.

Conclusion

The diamond mesh manufacturing industry is poised for growth, driven by its essential applications across various sectors. As manufacturers continue to innovate and adapt to changing market demands, the future of diamond mesh seems bright. By emphasizing quality, sustainability, and customer-focused solutions, diamond mesh manufacturers are not only meeting the needs of today's customers but are also setting the stage for a sustainable and resilient building infrastructure for the future. Whether for security, aesthetics, or industrial safety, diamond mesh remains an indispensable product in the modern manufacturing landscape.

-

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025