Dec . 11, 2024 09:27 Back to list

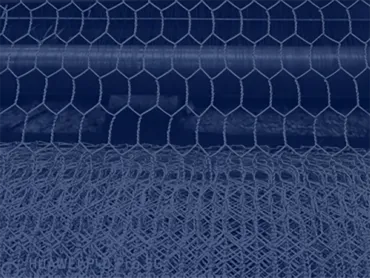

diamond mesh factory

Understanding Diamond Mesh Factory An Insight into Production and Applications

Diamond mesh, also known for its unique diamond-shaped openings, plays a crucial role in various industries. From agriculture to construction, its versatility and durability make it an essential material. In this article, we will delve into what a diamond mesh factory is, the production process, and its applications across different sectors.

What is Diamond Mesh?

Diamond mesh refers to a type of wire mesh characterized by its diamond-shaped openings. This mesh can be made from various materials, including steel, aluminum, and plastic, and its configuration offers excellent strength-to-weight ratios. The design enhances airflow and visibility while preventing the intrusion of larger objects. This makes diamond mesh an ideal choice for fencing, safety barriers, and many other uses.

The Diamond Mesh Factory Process

A diamond mesh factory involves numerous stages to transform raw materials into finished products. Understanding this process provides insights into the quality and efficiency of the final output.

1. Material Selection The first step in producing diamond mesh is the selection of appropriate materials. Steel wires are commonly used due to their strength and durability, while aluminum may be chosen for its lightweight characteristics. Quality control measures are implemented during this stage to ensure that only high-grade materials are selected.

2. Wire Drawing Once the materials are selected, they undergo a wire drawing process. This involves pulling the metal through a series of dies to reduce its diameter while increasing its length. The wire must have consistent thickness and tensile strength, which are essential properties for making robust diamond mesh.

3. Weaving The weaving process is where the diamond shape begins to take form. The drawn wires are interlaced in a pattern that creates the characteristic diamond apertures. This can be done manually or through automated machines, which help maintain uniformity and precision in the product.

4. Post-Processing After weaving, the mesh often requires additional treatment. This may include galvanization to prevent rust and corrosion, coating for aesthetic appeal, or further heat treatment to enhance strength. Quality assurance teams inspect the mesh to ensure it meets industry standards before it is packaged for distribution.

diamond mesh factory

5. Packaging and Distribution Finally, the finished diamond mesh is carefully packaged to prevent damage during transportation. Factories often have dedicated logistics teams that ensure timely delivery to clients worldwide. Customer relations play a vital role at this stage, as responding to inquiries and understanding client needs helps build lasting business relationships.

Applications of Diamond Mesh

Diamond mesh finds applications in a myriad of sectors due to its unique properties

. Here are some common applications- Fencing One of the most popular uses of diamond mesh is in fencing. It provides a secure barrier around properties, parks, and agricultural land while allowing airflow and visibility.

- Construction In the construction industry, diamond mesh is used as reinforcement in concrete structures. Its strength helps improve the durability of buildings and prevents cracking.

- Safety Barriers Diamond mesh is often employed in creating safety barriers for construction sites. Its robust design ensures that materials and people are contained within designated areas.

- Agricultural Uses In agriculture, diamond mesh is used for livestock enclosures and crop protection. It effectively keeps animals safe while allowing sunlight and water to reach the plants.

- Security Solutions Many businesses utilize diamond mesh for security systems, including window screens and industrial fencing, to deter theft and vandalism.

Conclusion

In conclusion, a diamond mesh factory plays a pivotal role in producing this versatile material that serves various industries. From the meticulous selection of raw materials to the intricate weaving process and rigorous quality control, every step is crucial in ensuring the final product meets high standards. As industries continue to evolve, the demand for diamond mesh will likely grow, driven by its unique advantages and broad range of applications. Understanding the intricacies of diamond mesh production equips industries to make informed decisions about their material needs and contributes to enhanced efficiency and safety across sectors.

-

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025