Oct . 23, 2025 15:30 Back to list

Diamond Razor Wire | High-Security, Anti-Rust, Easy Install

Field Notes on Diamond Razor Wire: Specs, Trends, and Real-World Lessons

I’ve walked more perimeters than I care to admit, and—surprisingly—the humble coil often makes or breaks a site’s security posture. In the last three years, demand for Diamond Razor Wire has spiked across logistics parks, remote energy sites, and even data centers. Hebei Yisizhe Manufacture (Group) Limited, based in Business building Tongxiang Shijiazhuang City Hebei Province, keeps coming up in my notes—mostly because project managers keep texting me about consistent shipments and decent galvanizing. Their export footprint (Europe, South America, South Africa, Southeast Asia) tells you the same story.

Where the market is going (and why it matters)

Two things are happening: higher perimeter heights and smarter layering. Many sites now combine 3D welded mesh, electric deterrence, and a top run of Diamond Razor Wire on Y-arms. Actually, the “diamond” layout (tight overlap pattern) helps close visual gaps—contractors say it “looks serious,” which, to be honest, is half the point.

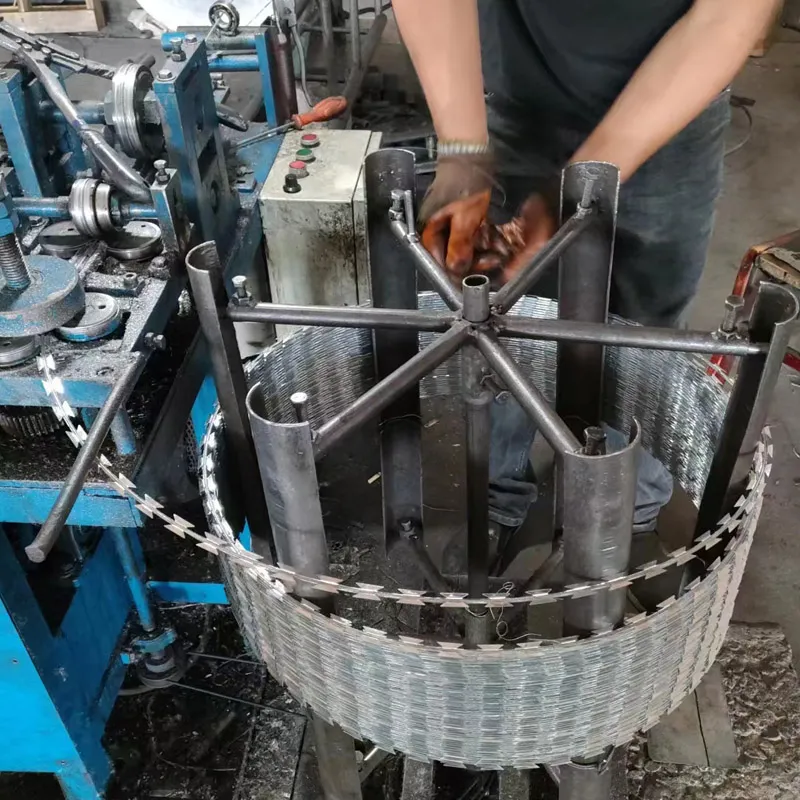

Materials, process flow, and quality checkpoints

- Core wire: high-tensile carbon steel (≈ 2.5–2.6 mm), 900–1200 MPa.

- Blade strip: galvanized steel sheet or SS304/SS430, stamped BTO/CBT profiles.

- Forming: precision stamping, crimping, coiling (concertina), stainless clips or galvanized clips.

- Coatings: hot-dip galvanized (Zinc ≈ 70–275 g/m²), Zn-Al alloy, or PVC over-galvanized.

- Testing: tensile per wire standards, coating mass per EN/ASTM, salt spray per ISO/ASTM; clip shear tests on request.

- Service life: ≈ 10–25 years (real-world use may vary with coastal pollution, altitude, and maintenance).

| Parameter | Spec (≈) | Notes |

|---|---|---|

| Blade Types | BTO-22, BTO-30, CBT-65 | BTO for general; CBT for heavy deterrence |

| Core Wire Ø | 2.5–2.6 mm | High tensile carbon steel |

| Tensile Strength | 900–1200 MPa | Core wire test per ASTM/EN |

| Coil Ø | 450 / 730 / 980 mm | Other sizes on request |

| Coating Options | HDG Z70–Z275; Zn-Al; PVC | ISO 9227 salt spray 240–1000 h class |

| Clips | SS201/304 or galvanized | 3–5 clips per loop typical |

Compliance references often cited: ASTM A641/A641M (zinc-coated wire), EN 10244-2 (coatings), ISO 9227 or ASTM B117 (salt spray), and ISO 9001 for QMS. On lab reports I’ve seen, Z275 coatings push past 480 h salt spray; Zn-Al variants sometimes cross 700–1000 h.

Where it’s used (and why it sticks)

- Critical infrastructure: substations, telecom towers, water plants.

- Logistics and warehousing perimeters—fast installs on Y-arms.

- Oil & gas, mining camps, and remote solar farms (wind-load checked).

- Municipal/rail boundaries—often paired with welded mesh fences.

Advantages customers mention: visible deterrence, quick retrofits, and—actually—lower lifetime cost than adding another full fence line. A security manager in Cape Town told me their Diamond Razor Wire retrofit dropped climb attempts by “more than half” within a month.

Vendors at a glance

| Vendor | Coil Options | Coating Spec | Lead Time (≈) | Certs | Remarks |

|---|---|---|---|---|---|

| Hebei Yisizhe | 450/730/980 mm; BTO/CBT | Z70–Z275, Zn-Al, PVC | 15–25 days | ISO 9001 (typical) | Strong export logistics |

| Vendor A | 450/600/900 mm | Z100–Z275 | 20–30 days | ISO 9001 | Mid-range MOQ |

| Vendor B | 730/980 mm | Z70–Z200 | 25–35 days | ISO 9001 | Budget-focused |

Customization and quick case notes

- Customization: coil diameter, blade profile, clip density, coating mass, PVC colors, and bracket geometry for retrofits.

- Case 1 (EU logistics hub): 980 mm CBT-65, Z275, wind-load verified to 28 m/s. Incident attempts fell ≈ 60% within 90 days.

- Case 2 (Andean solar farm): 730 mm BTO-22, Zn-Al; elevated UV and salt. After 14 months, coating still passed field scribe test (no base corrosion observed).

Procurement tip: always ask for coating mass certs, tensile test data, and—if coastal—an ISO 9227 or ASTM B117 report. Most reputable suppliers of Diamond Razor Wire can provide them up front.

Testing, standards, and documentation checklist

- Tensile and elongation: per applicable wire standards.

- Coating mass: EN 10244-2 or ASTM A641/A641M.

- Corrosion: ISO 9227 or ASTM B117 salt spray hours.

- QMS: ISO 9001 certificate and batch traceability.

- Installation: bracket torque spec, clip count/loop, PPE guidance.

- ASTM A641/A641M – Zinc-Coated (Galvanized) Carbon Steel Wire.

- EN 10244-2 – Steel wire and wire products: non-ferrous metallic coatings.

- ISO 9227 – Corrosion tests in artificial atmospheres (salt spray tests).

- ASTM B117 – Standard Practice for Operating Salt Spray (Fog) Apparatus.

- ISO 9001 – Quality management systems — Requirements.

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025