Aug . 19, 2024 05:22 Back to list

Current Pricing for Welded Wire Mesh Rolls and Market Trends

Understanding Welded Mesh Roll Prices Factors and Considerations

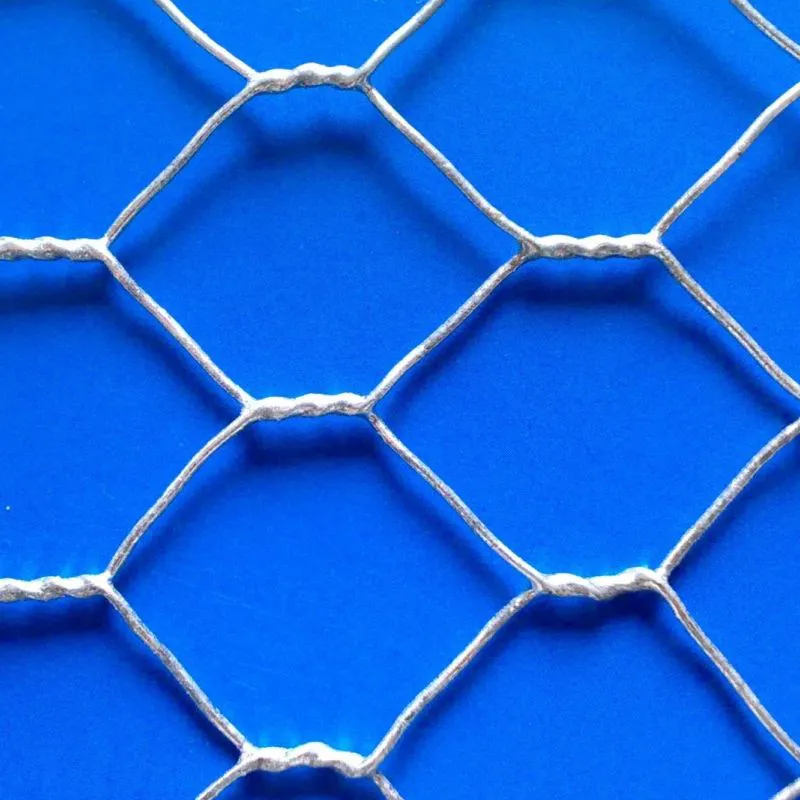

Welded mesh rolls have become increasingly popular in various industrial and construction applications due to their durability, strength, and versatility. They are extensively used in fencing, animal containment, reinforcement in construction, and as structural supports in various projects. However, the cost associated with welded mesh rolls can vary significantly based on several key factors. This article will explore these factors to provide a comprehensive understanding of welded mesh roll prices.

1. Material Type

The material used to manufacture welded mesh plays a crucial role in determining its price. Common materials include mild steel, stainless steel, and galvanized steel. Mild steel is often the most affordable option, but it may not offer the same level of corrosion resistance as galvanized or stainless steel. Stainless steel, while more expensive, provides superior corrosion resistance and durability, making it suitable for applications in harsh environments. Therefore, selecting the right material based on the specific requirements of your project can impact the overall cost of welded mesh rolls.

2. Wire Diameter and Mesh Size

The gauge or diameter of the wire and the size of the mesh openings also significantly influence welded mesh roll prices. Thicker wires typically command higher prices due to the increased amount of material used and enhanced strength for heavy-duty applications. Moreover, smaller mesh sizes, which provide higher levels of containment and structural integrity, may also be priced higher than larger openings. It is essential to assess the functional requirements of your project when considering the wire diameter and mesh size to balance performance and cost.

3. Roll Dimensions

weld mesh roll price

Welded mesh rolls come in various dimensions, including different lengths and widths. Generally, larger rolls or those with greater surface area will cost more than smaller ones. When purchasing welded mesh rolls, it is important to evaluate your project needs carefully; purchasing larger rolls may reduce the price per square meter, but it may also lead to excess material if not needed. Therefore, precise measurements can help optimize costs while ensuring you have the necessary materials for your project.

4. Production Process and Quality Standards

The manufacturing process and the quality standards adhered to during production can also affect welded mesh roll prices. High-quality welded mesh, produced under strict industry standards, ensures durability and reliability. Manufacturers that utilize automated processes and advanced technologies often charge a premium for their products due to improved quality control and reduced risk of defects. Investing in quality may initially cost more, but it can offer significant cost savings over time by reducing maintenance and replacement needs.

5. Market Demand and Economic Factors

Like any commodity, the price of welded mesh rolls can be influenced by market demand and prevailing economic conditions. Factors such as construction activity, supply chain fluctuations, and the availability of raw materials can lead to price volatility. During periods of economic growth, increased demand for construction and industrial projects can drive prices up, while slower economic conditions may lead to reductions in cost. Staying informed about market trends can aid consumers in making timely purchasing decisions.

Conclusion

In summary, understanding the factors affecting welded mesh roll prices is crucial for making informed purchasing decisions. By considering the material type, wire diameter and mesh size, roll dimensions, production quality, and prevailing market conditions, buyers can better navigate the complexities of pricing and select the appropriate welded mesh rolls for their projects. Whether for construction, fencing, or reinforcement applications, investing time in research can lead to better choices and cost-efficiency.

-

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025