Dec . 11, 2024 06:13 Back to list

Nail Manufacturing Solutions for Quality and Efficiency in Production Process

Exploring the Common Nail Factory A Manufacturing Marvel

In the vast landscape of manufacturing, few industries are as unassuming yet essential as that of nail production. Among the myriad of hardware items, common nails stand out as a cornerstone of construction and carpentry. The common nail factory is where this essential product comes to life, transforming raw materials into an indispensable tool utilized in countless applications.

The Heart of Production

A common nail factory is a hub of activity, where efficiency meets precision. The process begins with raw materials, typically high-quality steel wire. Steel is chosen for its tensile strength, ensuring that the nails are capable of holding structures together securely. The wire is fed into specialized machinery designed to cut, shape, and finish the nails with remarkable speed and accuracy.

The Manufacturing Process

The manufacturing process in a common nail factory involves several critical steps. First, the steel wire is unspooled and cut into lengths that correspond to the desired size of the nails. This is often done using high-speed cutting machines that ensure uniformity. Next, the cut wire pieces are fed into a die where they are formed into the typical nail shape—pointed at one end and flat on the other to accommodate hammers.

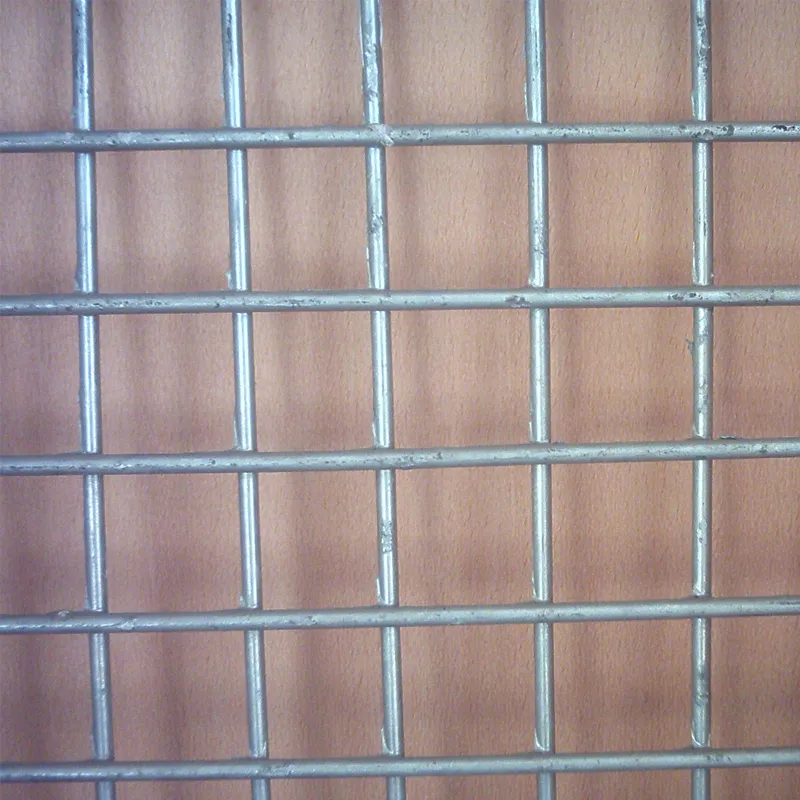

Once the nails are formed, they go through a process called hardening. This involves heating the nails to high temperatures and then cooling them rapidly, which increases their strength and durability. After hardening, the nails might be coated with materials like zinc or galvanized finishes to protect against rust and corrosion, making them suitable for outdoor use.

Quality Control

Quality control is an integral part of the manufacturing process in a common nail factory. Dedicated teams conduct inspections and tests at various stages to ensure that every nail produced meets industry standards. This may include checking for dimensional accuracy, assessing the weight, and performing drop tests to evaluate strength. Ensuring high quality not only builds a good reputation for the manufacturer but is also crucial for the safety and satisfaction of the end users.

common nail factory

Sustainability Practices

In recent years, many common nail factories have adopted sustainable practices to minimize their environmental impact. This includes recycling scrap metal from the production process and implementing energy-efficient machinery. Some factories utilize renewable energy sources, such as solar or wind power, to reduce their carbon footprint. These initiatives not only benefit the environment but also appeal to a growing consumer base that values sustainability in production.

Economic Impact

Common nail factories play a significant role in the local economy. They provide jobs for skilled and unskilled workers, contributing to community growth and economic stability. The demand for nails is consistently high, driven by the construction industry, DIY home projects, and furniture manufacturing. As such, the nail manufacturing sector can often be seen as a barometer of economic health, reflecting trends in housing and infrastructure development.

Global Reach

While many common nail factories serve local markets, others leverage global supply chains. Nails produced in one part of the world can find their way to construction sites in distant countries. The efficiency and affordability of nail production make them a competitive export product. This global reach not only expands business opportunities for manufacturers but also reflects the interconnectedness of modern economies.

Conclusion

The common nail factory, though often overlooked, is a vital component of the manufacturing sector. From the meticulous processes involved in production to the stringent quality controls in place, these factories exemplify efficiency and craftsmanship. As we continue to build and create, the humble common nail will remain an essential tool, symbolizing the intersection of industry and necessity. As we look towards the future, these factories are poised not only to adapt but to innovate, ensuring that nails continue to play their critical role in construction and beyond. In a world filled with complex technologies and advanced materials, the simplicity and reliability of a common nail remind us of the foundational elements of building—both literally and metaphorically.

-

Weather Resistance Properties of Quality Roofing Nails

NewsAug.01,2025

-

How Galvanised Iron Mesh Resists Corrosion in Harsh Environments

NewsAug.01,2025

-

Creative Landscaping Uses for PVC Coated Wire Mesh Panels

NewsAug.01,2025

-

Common Wire Nail Dimensions and Their Specific Applications

NewsAug.01,2025

-

Choosing the Right Welded Wire Sheets for Agricultural Fencing

NewsAug.01,2025

-

Anti - Climbing Features of Razor Wire Barriers

NewsAug.01,2025