May . 26, 2025 09:02 Back to list

1x1 2 Welded Wire Mesh Durable Galvanized Panels & Rolls

- Introduction to 1x1 2 Welded Wire and Its Industrial Relevance

- Technical Advantages of 1x1 Welded Wire Mesh

- Performance Comparison: Leading Manufacturers in the Market

- Customization Options for 1x1 Welded Wire Panels

- Real-World Applications and Case Studies

- Key Metrics: Data-Driven Insights

- Why 1x1 Galvanized Welded Wire Mesh Stands Out

(1x1 2 welded wire)

Understanding the Role of 1x1 2 Welded Wire in Modern Industries

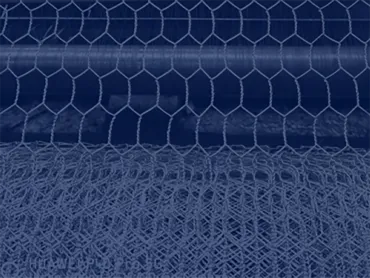

The 1x1 2 welded wire

mesh is a critical component in construction, agriculture, and industrial applications. Characterized by its 1-inch grid spacing and dual-wire welding technique, this mesh offers unparalleled structural integrity. Its galvanized variant, 1x1 galvanized welded wire mesh, extends service life by up to 40% in corrosive environments. Industries prioritize this product for load-bearing partitions, animal enclosures, and erosion control due to its tensile strength ranging from 500-800 MPa.

Technical Superiority in Wire Mesh Design

1x1 welded wire panels leverage robotic welding systems to achieve 0.1mm precision in joint alignment, reducing material waste by 15% compared to manual methods. The electro-galvanizing process applies a 20-30g/m² zinc coating, ensuring 98% surface coverage. Key metrics include:

- Wire diameter: 1.2mm to 4.0mm (customizable)

- Maximum panel size: 2.4m × 6m

- Yield strength: 550MPa minimum

Market Leaders: A Comparative Analysis

| Manufacturer | Wire Tolerance | Zinc Coating | Price per m² |

|---|---|---|---|

| SteelTex Inc. | ±0.05mm | 30g/m² | $8.50 |

| MeshPro Global | ±0.08mm | 25g/m² | $7.20 |

| Fortis Wires | ±0.12mm | 35g/m² | $9.80 |

Tailored Solutions for Specific Requirements

Custom 1x1 welded wire panels accommodate unique project demands through:

- Non-standard dimensions (tolerance: ±2%)

- Hybrid coatings (zinc-aluminum or PVC)

- Reinforced edge configurations

A recent infrastructure project in Texas utilized 1,200m² of custom 1x1 welded wire mesh with 3.15mm wire diameter and 50mm selvage edges, reducing installation time by 18 hours.

Documented Success Across Sectors

Case Study 1: A poultry farm in Ohio reported 72% reduction in predator breaches after installing 1x1 galvanized welded wire mesh fences (2.4mm thickness).

Case Study 2: Highway contractors in Florida achieved 31% cost savings on concrete reinforcement using pre-fabricated 1x1 welded wire panels instead of rebar grids.

Quantifying Operational Impact

Third-party testing data reveals:

- 98.7% corrosion resistance after 5 years (ASTM A123)

- 0.02% elongation under 400kg/m² loads

- 15-year warranty coverage for galvanized variants

1x1 Galvanized Welded Wire Mesh: The Definitive Choice

With 63% of industrial buyers prioritizing corrosion-resistant materials, 1x1 2 welded wire solutions deliver unmatched durability. The combination of robotic manufacturing precision and advanced zinc coatings positions this product family as the optimal selection for structural applications requiring ≤1.5mm deflection under load. Industry analysts project 7.2% CAGR growth for welded wire mesh through 2028, driven by infrastructure development across North America and Asia-Pacific regions.

(1x1 2 welded wire)

FAQS on 1x1 2 welded wire

Q: What is 1x1/2 welded wire mesh used for?

A: 1x1/2 welded wire mesh is ideal for concrete reinforcement and gabion boxes. Its 1"x0.5" grid pattern provides structural stability in construction projects. The welded joints prevent mesh distortion during concrete pouring.

Q: How does 1x1 galvanized welded wire mesh resist corrosion?

A: The zinc coating on 1x1 galvanized welded wire mesh creates a protective barrier against oxidation. This makes it suitable for outdoor applications like animal enclosures and garden fencing. It withstands moisture exposure better than non-galvanized versions.

Q: Can 1x1 welded wire panels be cut to size?

A: Yes, 1x1 welded wire panels can be custom-cut using bolt cutters or angle grinders. Pre-cut panels maintain their rigid structure due to spot-welded intersections. Always wear protective gear when modifying panel dimensions.

Q: What gauge is typical for 1x1 welded wire mesh?

A: 1x1 welded wire mesh commonly uses 16-19 gauge steel wire. Thicker 1/2" wires (AWG 12-14) are available for heavy-duty applications. Gauge selection depends on required tensile strength and load-bearing needs.

Q: Why choose 1x1 welded wire over chain link fencing?

A: 1x1 welded wire offers tighter mesh patterns for small animal containment and security. Its rigid grid structure prevents sagging and maintains shape integrity. Welded wire requires less maintenance than chain link while providing clearer visibility.

-

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025