Dec . 04, 2024 10:26 Back to list

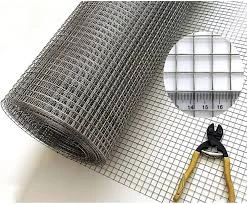

High Strength 1% 2% X 1% Welded Wire for Durable Applications

The Versatility and Applications of 1% 202% x 1% Welded Wire

Welded wire has become an essential material in various industries due to its strength, durability, and versatility. Among the different types available, the 1% 202% x 1% welded wire stands out for its unique properties and a wide array of applications. This article explores the features of this specific type of welded wire, its manufacturing process, benefits, and its applications across various sectors.

Understanding 1% 202% x 1% Welded Wire

The designation 1% 202% x 1% refers to the specifications of the welded wire mesh, including the wire diameter, spacing, and overall strength parameters. Typically, the 1% could refer to the mesh's wire thickness, while 202% might represent the tensile strength, indicating a robust material capable of withstanding significant loads. The dimensions (or spacing) of x 1% denote the configuration of the mesh, allowing for versatility depending on the intended use.

Manufacturing Process

The manufacturing of welded wire involves a precision process where wires are arranged in a grid format and then welded at each intersection. This method ensures that the wires form a sturdy structure, making it ideal for applications where strength and integrity are crucial. The wires are usually made from high-quality steel, treated to withstand corrosion and environmental elements, enhancing their longevity.

The welding process itself employs advanced technology, ensuring uniformity and precision. With computers controlling the welding parameters, manufacturers can create custom wire meshes tailored to specific requirements while maintaining high standards of quality and safety.

Benefits of 1% 202% x 1% Welded Wire

One of the primary advantages of the 1% 202% x 1% welded wire is its high tensile strength. This feature makes it suitable for applications that demand increased load-bearing capacity. Additionally, the mesh's design minimizes the risk of deformation over time, ensuring that it retains its shape under pressure.

Moreover, the welded wire is known for its resistance to corrosion and rust, especially when treated or galvanized. This property makes it ideal for outdoor use, where exposure to varying weather conditions can lead to deterioration. The wire’s rigidity provides excellent support and stability, whether used for fencing, reinforcing concrete, or as a safety barrier.

1 2 x 1 welded wire

Applications

The applications of 1% 202% x 1% welded wire are vast and varied

1. Construction In the construction industry, this type of welded wire is frequently used for reinforcing concrete structures. Its strength enhances concrete's durability, making it suitable for highways, bridges, and buildings.

2. Fencing The robust design of welded wire makes it ideal for creating secure and durable fencing solutions. Whether for residential backyards, agricultural land, or industrial sites, the grid structure provides security and keeps unwanted intruders out.

3. Agriculture Farmers use welded wire for fencing livestock enclosures, protecting crops from wildlife, and constructing trellises for climbing plants. Its strength ensures that it can withstand the pressures of animals and natural elements.

4. Industrial Uses In industrial applications, welded wire can serve as safety barriers, storage racks, or even security cages for valuable equipment. Its versatility allows it to be adapted for various purposes, helping to enhance operational safety and efficiency.

5. DIY Projects For hobbyists and DIY enthusiasts, 1% 202% x 1% welded wire is a go-to material for crafting garden structures, decorative fencing, and other creative projects.

Conclusion

The 1% 202% x 1% welded wire exemplifies the balance between strength and flexibility, making it a valuable material across multiple industries. Its manufacturing process ensures high quality and consistent performance, while its diverse applications demonstrate its practicality and essential role in modern construction, agriculture, and beyond. As industries continue to seek durable and effective solutions, welded wire will undoubtedly remain a staple material for years to come.

-

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025