Feb . 08, 2025 08:00 Back to list

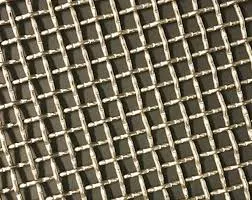

1 2 x 1 2 welded wire

When considering the optimal materials for construction or gardening projects, one cannot overlook the versatility and reliability of the 1 2 x 1 2 welded wire. As someone who has spent years exploring the vast range of materials available in the industry, I can attest that this particular type of welded wire mesh has become an indispensable asset for professionals across various sectors.

Security applications also benefit from this robust wire mesh. Around commercial properties or residential areas, the 1 2 x 1 2 welded wire fence acts as a formidable barrier that discourages trespassing. For property owners, this means peace of mind, knowing that their investments are protected by a sturdy, long-lasting material. Expertise in working with this material can further enhance its application benefits. Installing the wire correctly is crucial; factors such as tension, anchoring, and sealing play significant roles in maximizing its utility. Professionals recommend thorough site preparation and the use of appropriate tools and fasteners to secure a reliable installation. The materials used in the production of 1 2 x 1 2 welded wire contribute significantly to its credibility in professional circles. The zinc coating found in galvanized versions provides a sacrificial layer that combats the deleterious effects of moisture and other environmental contaminants, a factor critical when the wire is used in outdoor settings. Stainless steel alternatives offer an even greater resistance profile against corrosion, albeit typically at a higher cost, making them suitable for more specialized or demanding applications. The trustworthiness of 1 2 x 1 2 welded wire is also reflected in its widespread regulatory acceptance. Compliance with standards such as ASTM (American Society for Testing and Materials) ensures that the product has undergone rigorous testing to meet quality and safety benchmarks demanded by industry regulations, a factor that professionals prioritize when selecting materials for their projects. In summary, the 1 2 x 1 2 welded wire stands out in the market due to its exceptional combination of strength, versatility, and resistance to environmental factors. Its multifaceted applications in agriculture, construction, horticulture, and security underline its indispensability. Professionals who seek longevity, reliability, and efficiency will undoubtedly continue to favor this type of welded wire mesh as a cornerstone material in their endeavors. Its proven track record, coupled with compliance with industry standards, further bolsters its status as a trustworthy and authoritative choice for projects demanding durability and precision.

Security applications also benefit from this robust wire mesh. Around commercial properties or residential areas, the 1 2 x 1 2 welded wire fence acts as a formidable barrier that discourages trespassing. For property owners, this means peace of mind, knowing that their investments are protected by a sturdy, long-lasting material. Expertise in working with this material can further enhance its application benefits. Installing the wire correctly is crucial; factors such as tension, anchoring, and sealing play significant roles in maximizing its utility. Professionals recommend thorough site preparation and the use of appropriate tools and fasteners to secure a reliable installation. The materials used in the production of 1 2 x 1 2 welded wire contribute significantly to its credibility in professional circles. The zinc coating found in galvanized versions provides a sacrificial layer that combats the deleterious effects of moisture and other environmental contaminants, a factor critical when the wire is used in outdoor settings. Stainless steel alternatives offer an even greater resistance profile against corrosion, albeit typically at a higher cost, making them suitable for more specialized or demanding applications. The trustworthiness of 1 2 x 1 2 welded wire is also reflected in its widespread regulatory acceptance. Compliance with standards such as ASTM (American Society for Testing and Materials) ensures that the product has undergone rigorous testing to meet quality and safety benchmarks demanded by industry regulations, a factor that professionals prioritize when selecting materials for their projects. In summary, the 1 2 x 1 2 welded wire stands out in the market due to its exceptional combination of strength, versatility, and resistance to environmental factors. Its multifaceted applications in agriculture, construction, horticulture, and security underline its indispensability. Professionals who seek longevity, reliability, and efficiency will undoubtedly continue to favor this type of welded wire mesh as a cornerstone material in their endeavors. Its proven track record, coupled with compliance with industry standards, further bolsters its status as a trustworthy and authoritative choice for projects demanding durability and precision.

Next:

Latest news

-

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025