Oct . 27, 2025 14:40 Back to list

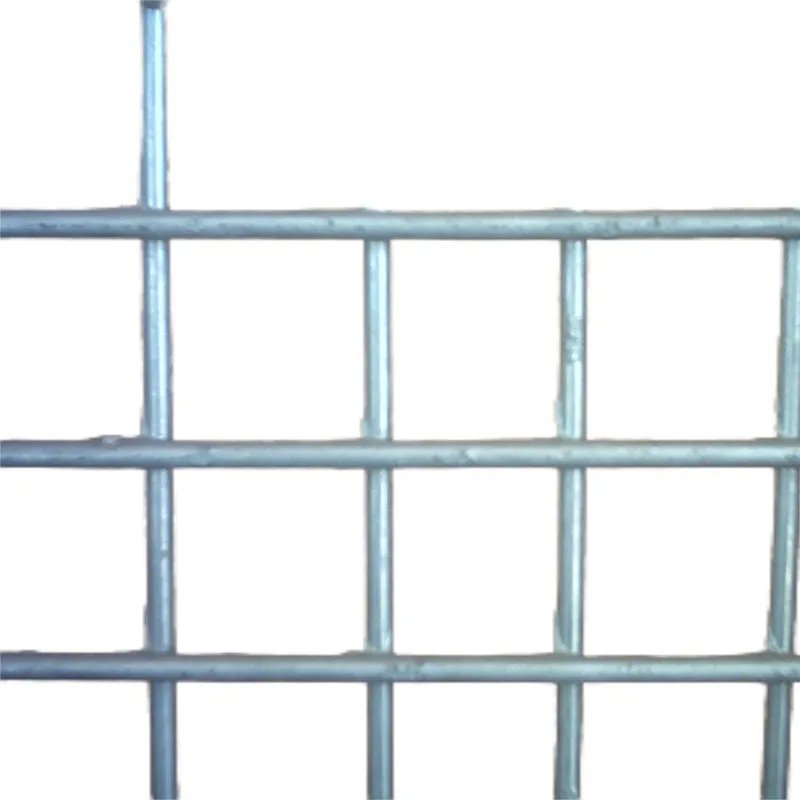

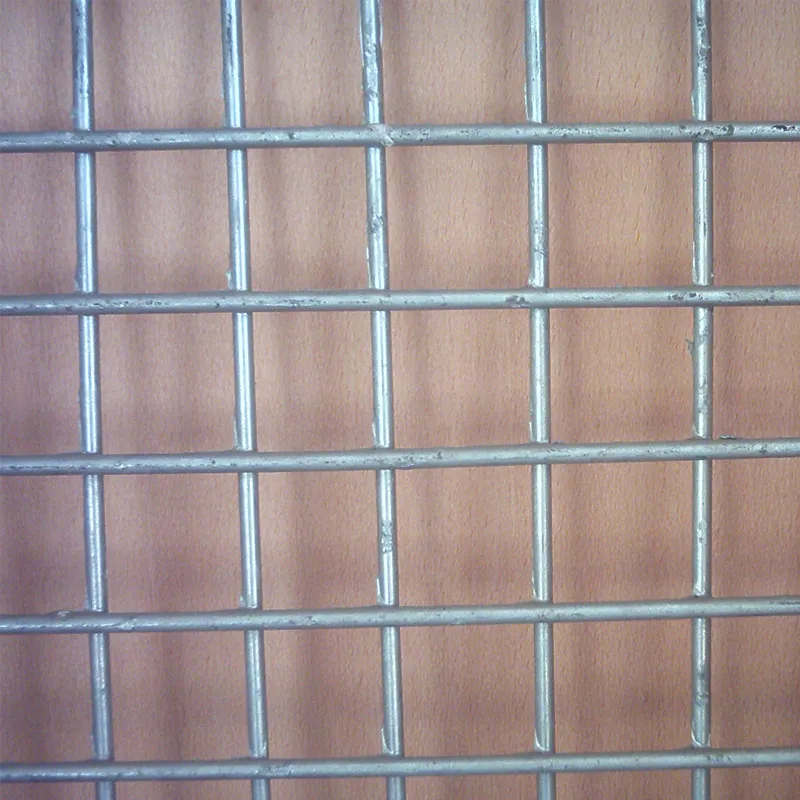

Welded Mesh Panels – Durable, Precise, Galvanized

Field Notes From the Yard: Why Welded Mesh Panels Keep Winning Specs

I’ve stood on too many job sites where time and weather were both misbehaving. In those moments, the materials that install fast, stay straight, and don’t rust out early tend to become your favorites. The product here—marketed as “Welded Mesh Sheet” from a manufacturer in Business building Tongxiang, Shijiazhuang City, Hebei Province—ticks those boxes. And, to be honest, it’s not just for construction; agriculture, aquaculture, transport yards, even office storage all love it.

Quick take: where Welded Mesh Panels actually get used

You’ll spot them as machine guards, animal fencing, garden and wood fences, window guards, passage fencing, poultry cages, egg baskets, storage bins, and the decorative stuff that always survives warehouse moves. In construction, ordinary welded wire mesh doubles as panel material and partition nets—frankly ideal for new high-rise builds where speed and uniformity matter.

Spec snapshot (real-world use may vary)

| Parameter | Typical Range | Notes |

|---|---|---|

| Wire diameter | 1.5–6.0 mm (≈14–4 gauge) | Q195/Q235 carbon steel; 304/316 stainless optional |

| Mesh opening | 12.7×12.7 mm to 100×100 mm | Tighter mesh for guards; larger for fencing |

| Sheet size | 1×2 m, 1.2×2.4 m, 2×3 m | Custom cuts and framed edges available |

| Coating | Hot-dip galv, electro-galv, PVC | Galv per ISO 1461/EN 10244-2; PVC colors on request |

| Tensile strength | ≥ 380–550 MPa | Aligned with ASTM A1064 for welded wire reinforcement |

| Service life | ≈8–25 years | Environment drives outcome; coastal reduces lifespan |

How it’s made (and tested)

- Materials: low-carbon steel wire (Q195/Q235), or 304/316 stainless for aggressive environments.

- Forming: straightening, resistance spot welding on automated lines; sheet flattening and trimming.

- Finishes: hot-dip galvanizing (ISO 1461), electro-galv or PVC coating; edge treatment if required.

- Testing: weld shear and pull tests (per A1064/AWS D1.3 guidance), aperture tolerance checks, zinc mass verification (EN 10244-2), salt spray to ASTM B117, PVC adhesion ASTM D3359.

- Docs: typical ISO 9001 quality system; mill certs and dimension reports on batch.

Typical field data: hot-dip galvanized panels reach >240 h neutral salt spray without red rust; PVC-coated versions have cross-hatch adhesion at 4B–5B. The numbers look dry, but on-site it simply means fewer callbacks.

Advantages you feel on the ground

- Rigid, square apertures—easy alignment, fewer field cuts.

- Fast install—panels act like “plug-and-play” barriers.

- Coating choices—balance cost vs. corrosion risk.

- Safe edges—optional folded or framed edges cut downtime and bandage costs.

Many customers say the batches are “boringly consistent.” That’s a compliment in our world.

Vendor landscape (my two cents)

| Vendor | Strengths | Watchouts |

|---|---|---|

| Yiszhe Wire Mesh (Hebei) | Wide spec range; hot-dip and PVC options; responsive on custom sizes; ISO-style QC docs. | Lead time can stretch in peak season—book early. |

| Trader A (multi-sourcing) | Fast quotes; large mix-and-match capability. | Batch-to-batch variance; coating spec needs extra checks. |

| Mill B (stainless specialist) | Excellent 304/316 workmanship; tight tolerances. | Higher MOQ and pricing; limited PVC color range. |

Customization that actually matters

For Welded Mesh Panels, the winning tweaks are: exact aperture and wire dia combo (safety vs. visibility), edge folding/framing, post spacing compatibility, and coating thickness. If you’re near the coast, ask for heavier zinc or go stainless; inland farming usually runs fine with PVC over electro-galv.

Mini case files

High-rise partition nets, Southeast Asia: 1.8×3 m panels, 50×50 mm, 3.5 mm wire, hot-dip galv. Installer cut labor by ~18% because panels stayed flat and true. After 14 months, no red rust at coastal edge—pleasant surprise.

Poultry complex, inland EU: PVC-coated 25×25 mm for brooders; workers cited “cleanability” and zero snags. Adhesion checked to ASTM D3359 at 5B. The client reordered within a quarter—always telling.

Bottom line

Welded Mesh Panels are not glamorous, but they’re the quiet backbone of fencing, guarding, and partitioning. If the spec hits known standards and the coating is honest, they just work. And when materials just work, everyone goes home earlier.

Authoritative sources

- ASTM A1064/A1064M – Standard Specification for Steel Wire and Welded Wire Reinforcement.

- ISO 1461 – Hot dip galvanized coatings on fabricated iron and steel articles.

- EN 10244-2 – Steel wire and wire products: Non-ferrous metallic coatings on steel wire.

- ASTM B117 – Standard Practice for Operating Salt Spray (Fog) Apparatus.

- ASTM D3359 – Standard Test Methods for Rating Adhesion by Tape Test.

- BS 4483 – Steel fabric for the reinforcement of concrete.

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025