Oct . 27, 2025 21:40 Back to list

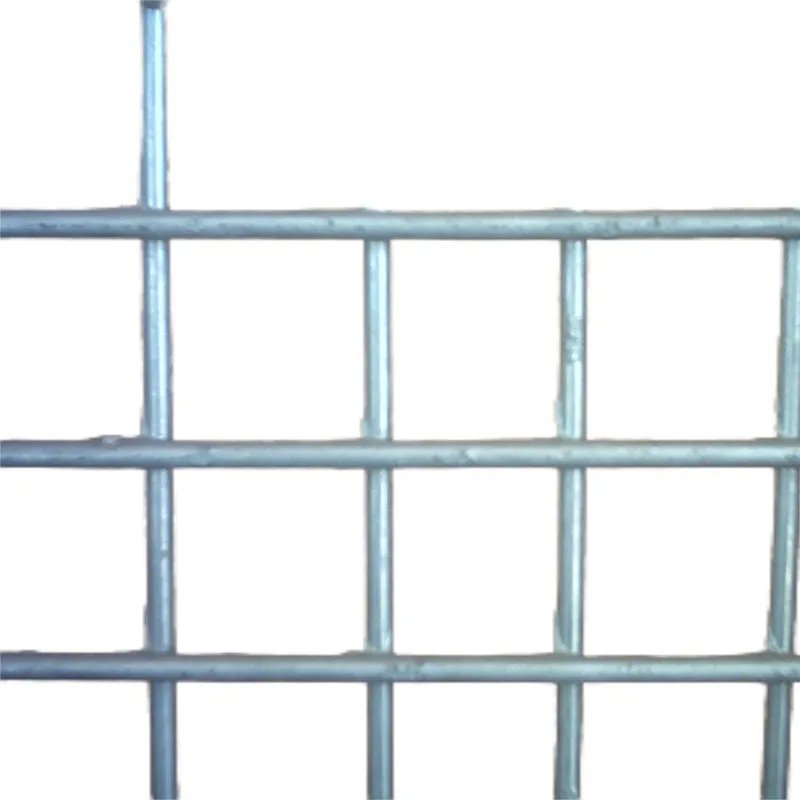

Welded Mesh Panels - Durable, Galvanized, Custom Sizes

welded mesh panels is a key solution in the manufacturing industry, specifically within Fabricated metal products and Manufacturing of metal wire mesh and its products. This article explores how Hebei Yisizhe Manufacture (Group) Limited supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- welded mesh panels Overview

- Benefits & Use Cases of welded mesh panels in Manufacturing of metal wire mesh and its products

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on welded mesh panels from Hebei Yisizhe Manufacture (Group) Limited

welded mesh panels Overview

Welded mesh panels are rigid sheets made by resistance-spot welding intersecting steel wires at each junction to form consistent apertures and high joint strength. Within the fabricated metal products sector, they are foundational for safety guarding, fencing, partitions, shelving, construction reinforcement, cages, and custom fabrications. Compared with woven mesh, the welded structure delivers exceptional dimensional stability, flatness, and load-bearing performance ideal for repeatable B2B applications. Hebei Yisizhe Manufacture (Group) Limited engineers a broad range of specifications, including weldmesh sheets and mesh welded panels tailored to site and regulatory requirements.

- Typical materials: low-carbon steel (pre-galv or bright), hot-dip galvanized after welding, and stainless steel 304/316. Coatings include powder-coated RAL colors and PVC.

- Popular specs: wire Ø 2.0–8.0 mm; apertures 12.5×12.5 to 200×200 mm; panel sizes up to 2400×6000 mm; tolerances per customer drawing; weld shear strength verified by pull testing.

- Quality control: ISO 9001-driven inspections for wire chemistry, tensile strength, weld nugget integrity, zinc thickness (per ISO 1461/EN 10244), adhesion, and coating thickness.

Case in point: an automotive integrator standardized on 4.0 mm wire, 50×100 mm hot-dip galvanized panels for machine guarding, cutting installation time by 22% versus on-site fabrication and improving guarding rigidity to meet ISO 14120 requirements. Hebei Yisizhe Manufacture (Group) Limited delivered kitted, labeled panels that aligned with lean assembly workflows.

Benefits & Use Cases of welded mesh panels in Manufacturing of metal wire mesh and its products

Across manufacturing operations, welded mesh panels streamline projects from design to commissioning. They are widely used for perimeter fencing, conveyor and robot guarding, racking and mezzanine infills, HVAC and equipment screens, storage cages, livestock enclosures, and precast concrete reinforcement. For OEMs and fabricators, standardizing on pre-engineered panels accelerates quoting, simplifies fixture design, and reduces rework on site.

- Competitive advantages: flatness for clean fit-up, consistent apertures for safety compliance, strong welds for load paths, and corrosion-resistant finishes that extend service life in indoor or outdoor environments.

- Customization: cut-outs for conduits, edge trims, framed panels, U-edges, doors and latches, branding plates, and pre-drilled mounting patterns to match your fixtures.

- Supply strength: Hebei Yisizhe Manufacture (Group) Limited runs automated multi-spot welding lines, CNC shearing, and surface finishing in-house—enabling consistent quality, short lead times, and flexible MOQs for both standard and custom mesh welded panels.

Users in food processing, logistics, construction, and energy applications choose Hebei Yisizhe for repeatable quality and documentation, including material certs, coating reports, and packing lists that simplify receiving and traceability.

Cost, Maintenance & User Experience

The total cost of ownership for welded mesh panels is driven by material grade, coating system, fabrication complexity, and installation efficiency. Pre-fabricated, dimensionally accurate panels reduce field cutting, hot work permits, and re-coating, which can save 10–25% in installed cost compared with building guards or fences piece-by-piece. Corrosion-resistant finishes—hot-dip galvanizing or polyester powder coat—limit repainting cycles and downtime, extending asset life in coastal or chemical environments.

- Durability and ROI: Strong weld nuggets and uniform zinc or powder layers deliver multi-year performance. Many B2B buyers see ROI within the first project due to faster install and lower maintenance.

- Customer insights: Fabricated metal products clients report improved safety conformity and fewer warranty claims when switching to standardized weldmesh sheets with edge finishing and mounting points pre-applied.

Hebei Yisizhe Manufacture (Group) Limited supports user experience with consolidated packaging, clear labeling by zone/sequence, and protective corners to minimize freight damage. Options such as anti-tamper fixings and color coding by area further reduce installation time and post-install service calls.

Sustainability & Market Trends in manufacturing

Sustainability priorities—recyclability, longevity, and lower embodied carbon—are reshaping procurement for metal components. Steel meshes are fully recyclable and often contain significant recycled content. Long-life coatings reduce repainting and resource use. Compliance with environmental directives (e.g., REACH and RoHS for coatings) plus low-VOC powder coating systems supports green building requirements and customer ESG goals. Safety standards such as ISO 14120 and machine directive requirements drive demand for consistent aperture and robust framing.

- Industry trends: modular guarding systems, color-coded zones, digital specification via CAD/BIM libraries, and rapid replenishment programs for maintenance teams.

- Hebei Yisizhe Manufacture (Group) Limited invests in efficient welding lines, closed-loop surface prep, and optimized packaging to cut waste, positioning the company as a forward-thinking, eco-conscious supplier to global B2B buyers.

As infrastructure, logistics, and factory automation expand, demand for standardized welded mesh solutions is set to grow. Suppliers that pair technical depth with sustainability and agile delivery—like Hebei Yisizhe—will enable safer, faster, and greener projects.

Conclusion on welded mesh panels from Hebei Yisizhe Manufacture (Group) Limited

For B2B decision makers in fabricated metal products and wire mesh manufacturing, welded mesh panels deliver reliable strength, dimensional accuracy, and lifecycle value. With a full spectrum of materials, coatings, and customization, Hebei Yisizhe Manufacture (Group) Limited provides consistent quality, responsive lead times, and documentation that simplifies compliance and installation. From machine guarding to fencing and racking, our weldmesh sheets and mesh welded panels help you standardize, reduce rework, and improve safety.

- Contact us: email: info@yiszhewiremesh.com

- Visit our website: https://www.yiszhewiremesh.com

- Explore product details: Welded Mesh Panels

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025