Oct . 16, 2025 12:10 Back to list

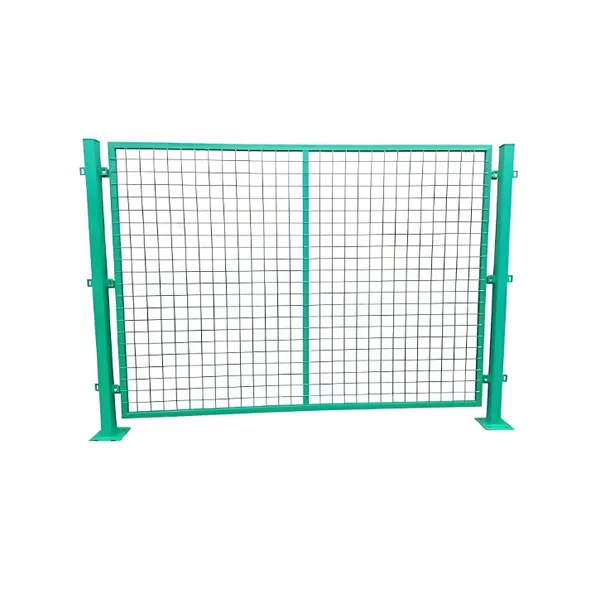

PVC Coated Wire Mesh – Durable, Corrosion‑Resistant Panels

PVC Coated Welded Wire Mesh: What’s Actually Working in 2025

If you’ve spent time on job sites, farms, or perimeter installs, you know the fence you choose either saves you headaches or invites them. Lately, I’ve been fielding a steady stream of questions about pvc coated wire mesh—and for good reason. The blend of welded steel strength with a PVC jacket that shrugs off weather is, frankly, a practical default for many specs.

What the market is saying

Contractors keep telling me corrosion resistance is non-negotiable now. Coastal projects, industrial plants, even schools want low-maintenance barriers. Surprisingly, price hasn’t scared people off—lifecycle cost wins. And yes, green or black finishes still dominate because they disappear into landscaping.

Technical overview (short and honest)

Core wire is typically low-carbon steel (Q195/SAE 1006–1008), welded at the intersections, then zinc-coated and PVC-jacketed by extrusion or dip-coating. Real-world PVC thickness sits around 0.3–0.9 mm; salt-spray performance depends on both the zinc and the polymer. Many customers say 5–12 years of service life outdoors is realistic, longer inland.

Typical specifications

| Item | Spec (≈, real-world may vary) |

|---|---|

| Core wire dia. | 1.0–3.0 mm (before coating) |

| PVC thickness | 0.3–0.9 mm |

| Mesh aperture | 12.7×12.7 mm, 25×25 mm, 50×50 mm, custom |

| Roll size / panel | 0.9–2.1 m high × 25–30 m rolls; 1×2 m panels |

| Colors | Green RAL6005, Black RAL9005, Gray; custom RAL |

How it’s made and tested

- Material: low-carbon steel drawn to gauge; zinc per ASTM A641/A641M.

- Process: resistance welding → zinc layer → PVC extrusion/dip → curing.

- Quality checks: mesh tolerance (ISO 9044), coating thickness (ISO 2808), adhesion (ASTM D3359), salt spray (ISO 9227).

- Indicative data: NSS 480–1000 h; adhesion 4B–5B; tensile ≥ 350–550 MPa (wire dependent).

Where it’s used (and why)

Construction hoarding, perimeter security, animal enclosures, orchard trellising, HVAC guards, and light-duty filtration. The real value of pvc coated wire mesh is low maintenance—wash it off, maybe cut back vegetation, that’s it. In fact, in coastal towns I’ve seen it outlast painted mild-steel panels easily.

Vendor snapshot (field-notes style)

| Vendor | Coating | Certs | Lead Time | Notes |

|---|---|---|---|---|

| Yiszhe (Tongxiang, Shijiazhuang, Hebei) | PVC 0.4–0.8 mm | ISO 9001; RoHS/REACH material statements | 10–20 days | Consistent welds; custom RAL colors |

| Import Brand B | PVC ≈0.3–0.5 mm | ISO 9001 | 30–45 days | Lower MOQ but lighter coating |

| Local Dealer C | Mixed stock | Varies | Immediate | Convenient; check batch quality |

Customization and small wins

Aperture tweaks to keep pets in (or pests out), heavier core wire for public sites, and color-matching to corporate RALs—these sound minor, but they make projects look intentional. We’ve seen pvc coated wire mesh panels pre-framed to cut install time by ≈20% on schools.

Mini case notes

- Coastal boardwalk, 800 m: pvc coated wire mesh replaced rusted chain link; 24 months in, no blistering, only salt washdowns.

- Poultry farm retrofit: smaller 12.7 mm aperture cut losses from wild birds; cleaning downtime reduced ≈15%.

- Light industry: HVAC guards with black PVC finish blend into facade—facilities manager happy; fewer complaints.

Final take

If you need durable, tidy-looking barriers without constant repainting, pvc coated wire mesh is, to be honest, a safe bet. Check coating thickness, zinc class, and test reports—then worry less about the weather and more about the work.

References

- ASTM A641/A641M – Zinc-Coated (Galvanized) Carbon Steel Wire

- ASTM A185/A185M – Steel Welded Wire Fabric, Plain

- ISO 9044 – Industrial Woven Wire Cloth and Screens

- ISO 2808 – Paints and Varnishes—Determination of Film Thickness

- ISO 9227 – Corrosion Tests in Artificial Atmospheres—Salt Spray Tests

- ASTM D3359 – Measuring Adhesion by Tape Test

- ISO 9001:2015 – Quality Management Systems

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025