Oct . 13, 2025 14:30 Back to list

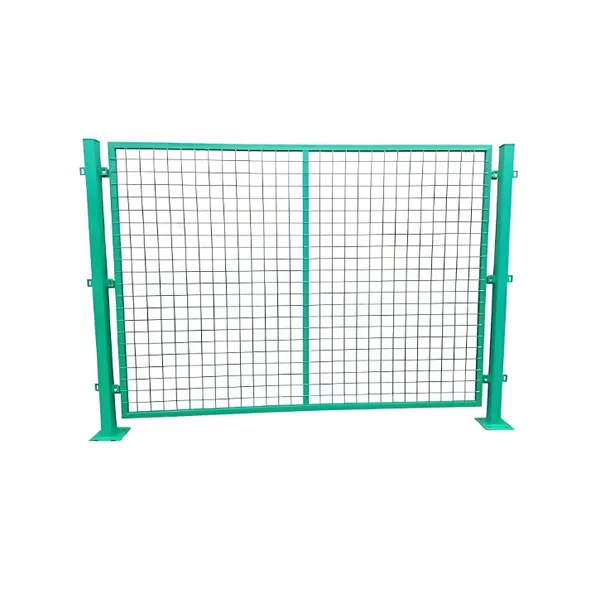

PVC Coated Wire Mesh | Durable, Corrosion-Resistant Panels

PVC Coated Welded Wire Mesh: field notes, specs, and what buyers really ask

If you’re speccing pvc coated wire mesh for a project, here’s the short version: the coating buys you time—against rust, UV, abrasion—and it keeps sites looking neat. I’ve walked enough yards and farms to see why: galvanized core for backbone, PVC jacket for weather. Origin on today’s product: Business building Tongxiang, Shijiazhuang City, Hebei Province. Solid manufacturing cluster, to be honest.

What’s trending on jobsites

Contractors want durable, color-stable panels that don’t scream “industrial.” Dark green and matte black remain the go-to. Anti-climb tighter apertures for school perimeters, plus powder/PVC hybrids are getting buzz. Prices do swing with steel and resin, but demand is steady in construction protection, agriculture, and light filtration. Many customers say they pick pvc coated wire mesh because it installs fast and looks tidy even after a muddy season.

Process flow (how it’s actually made)

- Material: Low-carbon steel wire (Q195/Q235), typically zinc-coated per ASTM A641 or equivalent.

- Welding: Resistance-welded into sheets/rolls; weld shear tests per ASTM A370 methods.

- Surface prep: Degrease, rinse, oxide removal; key for coating adhesion.

- Undercoat: Optional re-galv or phosphate to boost bonding.

- PVC coating: Fluidized-bed dip or extrusion; cure at controlled temp for uniform jacket.

- QC: Coating thickness gauge, cross-hatch adhesion (ASTM D3359), salt spray (ISO 9227), UV aging (ISO 4892-2).

Key specs (typical, real-world use may vary)

| Mesh aperture | Core wire Ø | After-coat Ø | Coating | Sizes | Colors |

|---|---|---|---|---|---|

| 12.7×12.7 mm to 100×100 mm | 1.0–4.0 mm | ≈1.4–5.0 mm | PVC ≈0.3–1.0 mm | Rolls 1×25 m; Panels 1×2 m, 1.5×3 m | Green RAL 6005, Black RAL 9005, others |

Service life: inland 10–20 years; coastal 5–12 years (salt/UV matter). For harsher sites, choose thicker zinc + thicker PVC. That combo makes pvc coated wire mesh surprisingly resilient for its price.

Testing, certifications, and data points

- Salt spray (ISO 9227): 720 h, no red rust on cut-free surfaces (sample set; project results vary).

- Adhesion (ASTM D3359): 4B–5B on milled panels.

- UV aging (ISO 4892-2, 1000 h): ΔE ≤ 2.5 on RAL 6005 samples.

- Compliance: RoHS/REACH statements available on request.

Where it’s used (and why)

- Building & site protection: temporary barriers, façade safety screens. - Agriculture: poultry runs, orchard fencing. - Filtration & cages: light-duty screens, HVAC guards. - Public works: parks, school perimeters, anti-climb zones. It installs quickly and cleans up well—maintenance teams like that.

Vendor snapshot (quick comparison)

| Vendor | Coating thickness | Certs | MOQ | Lead time | Customization |

|---|---|---|---|---|---|

| Yiszhe (Hebei) | ≈0.4–1.0 mm | RoHS/REACH, test reports | Low (project-based) | 10–20 days | Aperture, color, panel size |

| Generic importer | ≈0.3–0.6 mm | Basic CoC | Medium | 4–6 weeks | Limited SKUs |

| Local fabricator | ≈0.5 mm (on request) | Varies | Very low | Fast | High, but pricier |

Customization notes

Aperture, gauge, panel vs roll, and RAL color are easy toggles. For coastal jobs, ask for higher zinc on the core + thicker PVC. For schools, specify anti-climb apertures and black matte—less reflective, looks premium. It seems small, but hardware and post systems matter more than people expect.

Case snippets and feedback

Municipal park fence, inland EU: 1.8 m panels, RAL 6005, still presentable after 5 winters; minor touch-ups at cuts only. Poultry farm, coastal Asia: switched to thicker jacket; field checks at 30 months show no red rust away from fastener cuts. “Looks clean and outlives our timber posts,” one manager told me. That’s typical for pvc coated wire mesh when the spec is right.

Standards to reference

- ASTM A1064 (welded wire for reinforcement), ASTM A641 (zinc-coated steel wire), ASTM D3359 (adhesion), ISO 9227 (salt spray), ISO 4892-2 (UV), EN 10223-4 (fencing products). Good anchors for specs and submittals.

References:

- ASTM A1064/A1064M – Standard Specification for Steel Wire and Welded Wire Reinforcement.

- ASTM A641/A641M – Zinc-Coated (Galvanized) Carbon Steel Wire.

- ASTM D3359 – Standard Test Methods for Rating Adhesion by Tape Test.

- ISO 9227 – Corrosion tests in artificial atmospheres — Salt spray tests.

- ISO 4892-2 – Plastics — Methods of exposure to laboratory light sources — Xenon-arc.

- EN 10223-4 – Steel wire and wire products for fences — Welded mesh panels.

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025