Sep . 10, 2025 10:20 Back to list

Premium Gabion Cages for Sale | Durable & Affordable Gabion Boxes

Introduction to Gabion Solutions and Evolving Industry Trends

The continuous evolution of infrastructure and environmental engineering demands robust, sustainable, and adaptable solutions. In this context, gabion cages for sale have solidified their position as an indispensable component for a diverse array of civil engineering, hydraulic, and landscape architecture projects. These engineered structures, comprising durable wire mesh filled with natural stone, offer a unique combination of flexibility, permeability, and inherent strength, making them ideal for managing erosion, constructing retaining walls, and implementing channel stabilization. The global market for gabion solutions is experiencing substantial growth, driven by an increased focus on resilient infrastructure development, the adoption of eco-friendly construction methodologies, and the imperative to mitigate the impacts of climate-related natural disasters requiring robust geostructural stabilization.

Key industry trends underscore a pronounced shift towards advanced coating technologies, notably Galfan (zinc-aluminum alloy) and specialized PVC coatings, which significantly extend product longevity and enhance resistance to highly corrosive environments. Furthermore, the market is witnessing an accelerated adoption of prefabricated and modular gabion box systems, streamlining installation processes and substantially reducing on-site labor costs and project durations. As a leading gabion box supplier, we are observing a consistent and escalating demand for products that not only meet but often exceed stringent international quality and performance standards. This article will provide a comprehensive overview of the technical specifications, manufacturing processes, diverse application scenarios, and the competitive advantages of modern gabion solutions, empowering B2B decision-makers with the knowledge to select optimal engineering products.

The Advanced Manufacturing Process of High-Performance Gabion Cages

The superior quality and long-term performance of gabion cages for sale are directly attributable to a meticulous manufacturing process, commencing with the selection of premium raw materials and extending through sophisticated fabrication and rigorous quality assurance. Our production protocols are designed to consistently meet or surpass the exacting requirements of international standards such as ASTM A975 (Standard Specification for Double-Twisted Hexagonal Mesh Gabions) and EN 10223-3 (Steel wire mesh products for gabions), ensuring structural integrity and extended service life.

Detailed Process Flow:

- Wire Rod Procurement & Drawing:

- Corrosion-Resistant Coating Application:

The foundation of a durable gabion lies in the quality of its steel wire. We exclusively source high-tensile, low-carbon steel wire rods (e.g., SAE 1006 or equivalent). These rods undergo a controlled cold drawing process to achieve precise wire diameters, ensuring optimal tensile strength, ductility, and consistency required for the mesh fabric and binding wires.

Post-drawing, the wires receive a protective coating crucial for longevity. Options include:

- Hot-dip Galvanization: Wires are submerged in molten zinc, creating a metallurgically bonded coating with a minimum zinc mass of 240-300 g/m² (as per ASTM A641/A975), providing cathodic protection.

- Galfan (Zinc-5% Aluminum-Mischmetal) Coating: A superior alternative, offering enhanced corrosion resistance (often 2-3 times that of standard galvanization) due to the aluminum content. Coating mass typically matches galvanized standards.

- Double-Twisted Hexagonal Mesh: Wires are mechanically twisted together in a hexagonal pattern. This design prevents unraveling in the event of localized wire breakage, maintaining structural integrity.

- Welded Wire Mesh: Individual wires are precisely resistance-welded at their intersections, forming a rigid, square, or rectangular mesh. This type offers a more rectilinear appearance and often simplifies on-site assembly.

Mesh panels are cut to exact dimensions using automated machinery. For structural reinforcement, heavier gauge selvedge wires (typically 3.4mm to 5.0mm) are integrated along the perimeter of the gabion panels. This crucial step enhances the strength of the edges, providing increased resistance to deformation during filling and hydrostatic pressures in service.

For applications in highly aggressive environments (e.g., marine, acidic soils, polluted watercourses), an additional PVC coating is applied. This involves extruding a minimum 0.5mm thick PVC layer over the galvanized or Galfan-coated wire, forming a durable, impermeable barrier against chemical attack and abrasion, further extending the expected service life significantly.

Gabion components (base, front, back, sides, lid, and internal diaphragms for larger units) are either folded flat for compact shipping or partially pre-assembled into modular sections. They are then securely bundled and packaged to prevent damage during transit to the project site.

Throughout the entire manufacturing chain, stringent quality control protocols are enforced. This includes testing of raw wire tensile strength, elongation, coating mass and adhesion, mesh opening dimensions, and overall panel accuracy. Adherence to ISO 9001 standards ensures every gabion box delivered meets the highest performance criteria.

Technical Specifications and Performance Parameters

For B2B decision-makers and engineering professionals, a detailed understanding of the technical specifications of a gabion box is paramount. These parameters dictate the structural integrity, hydraulic performance, and environmental resilience of the final structure. Key specifications include the gauge and type of wire, mesh aperture size, material composition, and the specific corrosion-resistant coating applied. Each of these elements directly influences the gabion's ability to resist tensile forces, endure environmental exposure, and perform effectively over its design life.

Standard Gabion Box Technical Specifications

Careful consideration of these specifications is vital during the design phase. For instance, projects in aggressive environments or those demanding extended design lives will benefit from enhanced Galfan or PVC coatings. Similarly, the choice between double-twisted and welded mesh depends on factors such as required flexibility, aesthetic preferences, and the specific loading conditions. Our technical team provides expert consultation to assist clients in specifying the ideal gabion box configuration for their unique project demands, ensuring optimal performance and compliance.

Versatile Application Scenarios and Distinct Technical Advantages

The inherent adaptability of gabion cages for sale makes them an unparalleled solution across a wide spectrum of civil, hydraulic, and environmental engineering applications. Their structural and hydrological properties offer significant technical and economic advantages when compared to more traditional, rigid construction methodologies.

Key Application Areas:

- Retaining Walls & Slope Stabilization: Utilized for constructing gravity retaining walls, reinforced soil slopes, and stabilizing embankments. Gabions provide a flexible, monolithic structure capable of accommodating differential settlement and ground movement without compromising integrity, a critical advantage in unstable terrains.

- River & Channel Training Works: Essential for river bank protection, scour countermeasures, channel lining, weirs, and diversion structures. Their permeability dissipates hydraulic energy, reduces upstream velocities, and minimizes erosion while promoting natural sediment deposition.

- Bridge Abutments & Culvert Headwalls: Providing robust structural support and erosion protection at critical interface points where hydraulic forces can be significant. Their adaptability ensures long-term performance even with dynamic water flows.

- Coastal & Marine Protection: With appropriate anti-corrosion coatings (e.g., PVC-coated gabions), they serve as effective sea walls, revetments, and groynes to combat coastal erosion and protect infrastructure from wave action.

- Noise Attenuation Barriers: When filled with dense, sound-absorbing stone, gabion walls can be strategically deployed along highways, railways, and industrial areas to effectively reduce noise pollution.

- Architectural & Landscaping Features: Beyond their functional roles, gabions are increasingly integrated into modern landscape design for decorative walls, garden furniture, and aesthetically pleasing boundary structures, leveraging their natural, rustic appeal.

Technical Advantages:

- Exceptional Permeability: Gabion structures are inherently free-draining. This critical feature prevents the buildup of hydrostatic pressure behind retaining structures, eliminating the need for complex and costly drainage systems and mitigating the risk of structural failure due to water accumulation.

- Inherent Flexibility: Unlike rigid concrete or masonry structures, the wire mesh construction of a gabion box allows for significant deformation without structural failure. This flexibility is invaluable in areas prone to differential ground settlement, seismic activity, or dynamic loading, enhancing overall resilience.

- Superior Durability & Longevity: Manufactured with high-grade galvanized, Galfan, or PVC-coated steel wire, and filled with inert natural stone, gabions boast an impressive design life often exceeding 50 to 75 years, even in challenging environmental conditions.

- Environmental & Ecological Compatibility: Gabions seamlessly integrate with the natural landscape. Their permeable nature facilitates the establishment of vegetation within the stone fill over time, enhancing slope stability, promoting biodiversity, and providing a natural, aesthetically pleasing finish. This natural integration contributes to energy saving by reducing reliance on manufactured, high-carbon-footprint materials.

- Cost-Effectiveness: The ability to utilize locally sourced stone for infill significantly reduces transportation costs. Furthermore, the relatively straightforward installation process for gabion structures translates into lower labor requirements and overall project costs compared to traditional heavy construction methods.

- Advanced Corrosion Resistance: Multi-layered protective coatings provide robust defense against chemical degradation, abrasion, and oxidation. Galfan coatings offer superior performance in moderate to severe environments, while PVC coatings provide an unparalleled barrier in highly aggressive or saline conditions.

Vendor Comparison and Customized Engineering Solutions

The selection of an appropriate gabion box supplier is a pivotal decision that directly influences project success, from adherence to budget and timelines to the long-term performance and durability of the finished structure. Critical differentiating factors among vendors include the stringency of manufacturing quality, compliance with international standards, the extent of customization capabilities, and the provision of comprehensive pre- and post-sales technical support.

Comparative Analysis of Gabion Suppliers:

Leveraging Customized Gabion Solutions:

Recognizing the inherent variability and unique challenges presented by each infrastructure project, a distinguished gabion box supplier offers highly tailored solutions. Our customization capabilities are designed to integrate seamlessly with specific project parameters, including:

- Non-Standard Dimensions & Shapes: Production of gabions in precise, non-conventional lengths, widths, and heights to accommodate complex topographical constraints, intricate architectural designs, or specific structural loading requirements.

- Optimized Wire Gauge & Mesh Aperture: Adjusting the wire diameter and mesh opening size to fine-tune the structural performance, optimize for locally available stone infill, or meet specific aesthetic criteria for visibility.

- Specialized Coating Systems: Beyond standard galvanization and Galfan, we offer enhanced PVC formulations for extreme chemical resistance, UV stability, or bespoke color requirements for architectural integration.

- Integrated System Components: Supplying complementary materials such as heavy-duty geotextiles for filtration and separation, erosion control blankets for revegetation, or specialized lacing wire and fasteners, ensuring a fully integrated and optimized gabion system.

Our approach emphasizes collaborative engagement with project engineers and contractors, translating complex requirements into precision-engineered gabion cages for sale that deliver optimal performance, cost-efficiency, and long-term reliability.

Authoritativeness, Certifications, and Proven Case Studies

In the highly specialized B2B sector, credibility and trust are paramount, particularly for critical infrastructure materials like the gabion box. Our commitment to excellence is demonstrated through rigorous adherence to authoritative industry standards, comprehensive certifications, and a robust portfolio of successfully delivered projects. With over two decades of dedicated service, we have established ourselves as an industry leader, consistently partnering with governmental bodies, major construction conglomerates, and expert engineering consultants worldwide.

Certifications and Unwavering Quality Assurance:

- ISO 9001:2015 Certified Quality Management System: Our entire manufacturing and operational framework operates under the strict guidelines of ISO 9001. This internationally recognized standard ensures systematic processes, continuous improvement, and consistent product quality, providing clients with absolute confidence in every order.

- ASTM A975 Compliance: All double-twisted hexagonal mesh gabions and revet mattresses are meticulously fabricated to conform with ASTM A975/A975M-17. This specification covers the core wire, metallic coatings, PVC coatings, and the complete fabrication procedure, ensuring material and structural integrity.

- EN 10223-3 and CE Marking: Our products meet the demanding European standards for steel wire mesh products specifically for gabions. The CE marking affirms compliance with essential health, safety, and environmental protection requirements for products sold within the European Economic Area.

- State-of-the-Art In-house Testing Facilities: We maintain advanced laboratories equipped for comprehensive material testing, including wire tensile strength, elongation, coating mass and thickness, and salt spray corrosion resistance. This allows us to provide verifiable, batch-specific data and ensure every product meets design specifications.

Exemplary Application Case Studies:

Case Study 1: Major River Embankment Protection, Southeast Asia

Project Challenge: A critical agricultural region adjacent to a significant river in Southeast Asia faced severe and recurrent erosion during annual monsoon floods. Traditional, rigid concrete revetments were deemed unsuitable due to their lack of flexibility in dynamic hydraulic environments and high environmental impact.

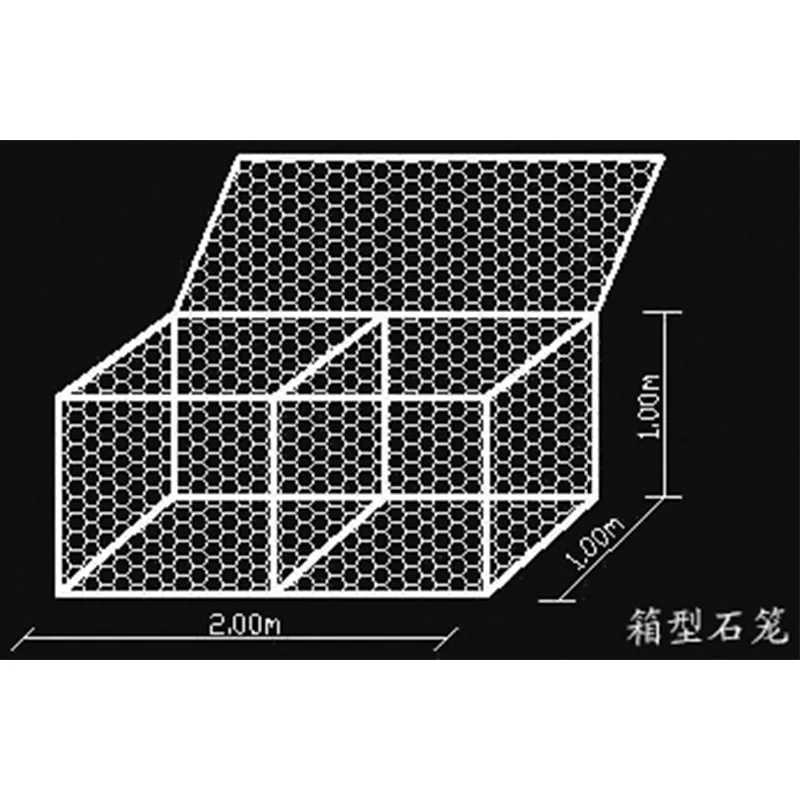

Engineered Solution: We collaborated closely with local engineering firms to supply a substantial volume—over 15,000 cubic meters—of Galfan-coated gabion box units (primarily 2x1x1m boxes and 3x1x0.5m Reno Mattresses). These were strategically deployed along a 2-kilometer stretch of riverbank. The inherent permeability of the gabion structures allowed for natural water dissipation, effectively mitigating hydrostatic pressure while providing robust bank reinforcement.

Outcome & Performance: The gabion-reinforced riverbanks have successfully withstood multiple severe high-flow events over a period exceeding five years, demonstrating exceptional resilience and stability. A notable ecological benefit has been the natural establishment of indigenous vegetation within the stone infill, further enhancing the long-term stability and ecological integration of the riverine environment. This project stands as a testament to the superior flexibility and hydraulic performance of engineered gabion solutions in challenging fluvial conditions.

Case Study 2: Highway Embankment Stabilization in Seismically Active Zone, North America

Project Challenge: The construction of a new arterial highway through a mountainous, seismically active region necessitated the urgent construction of a highly stable and resilient retaining wall to support a critical embankment. Traditional rigid concrete structures were cost-prohibitive and posed significant risks due to their inability to accommodate potential seismic-induced ground movements.

Engineered Solution: We provided bespoke, PVC-coated gabion box units, specifically engineered to withstand anticipated localized seismic stresses and differential ground settlement. The design incorporated heavy-gauge wire and optimized mesh sizing, ensuring a robust yet flexible structure. The PVC coating was selected for its enhanced durability and resistance to environmental degradation over the extended design life.

Outcome & Performance: The gabion retaining wall successfully provided the necessary support for the highway embankment, proving to be a highly resilient and cost-effective solution. Post-construction monitoring, spanning over a decade, has consistently confirmed the structure's exceptional ability to absorb ground movement without compromising its structural integrity. This project serves as a prime example of the superior flexibility, seismic resistance, and long-term reliability offered by expertly engineered gabion wall systems in challenging geological contexts.

Trustworthiness: Frequently Asked Questions, Lead Time, Warranty & Support

For B2B clients, establishing trustworthiness extends beyond product specifications to encompass transparency in operations, dependable logistics, and comprehensive after-sales support. As a leading gabion box supplier, we are committed to providing clear communication, reliable fulfillment, and expert assistance throughout the entire project lifecycle.

Frequently Asked Questions (FAQ):

Q1: What is the expected service life for your gabion cages?

A1: The service life varies based on the coating. Our standard hot-dip galvanized gabions are engineered for 25-35 years. Galfan-coated products typically achieve 40-50 years, while PVC-coated gabions offer the highest durability, frequently exceeding 75 years in aggressive environments, provided they are correctly designed, installed, and filled with appropriate, non-reactive stone.

Q2: Are gabion structures suitable for marine or highly saline environments?

A2: Yes, for marine or highly saline applications, we strongly recommend our PVC-coated gabions. The thick PVC layer acts as a robust barrier against saltwater corrosion, significantly extending the operational life of the structure. Galfan coating also offers superior performance over standard galvanization in such conditions due to its enhanced corrosion resistance.

Q3: What type of stone infill is recommended for your gabion boxes?

A3: The ideal stone infill should be durable, angular (to promote interlocking), non-friable, weather-resistant, and chemically inert. Typical sizes range from 75mm to 200mm (approximately 3-8 inches), ensuring they are larger than the mesh opening to prevent egress. Sourcing local, readily available quarry stone helps optimize project costs and minimize environmental footprint.

Q4: How does installation compare to traditional retaining structures?

A4: Gabion installation is generally simpler and faster than constructing traditional concrete or masonry walls. It typically involves assembling the wire mesh units, placing them, and then filling them with stone, often utilizing local labor and materials. This reduces the need for specialized equipment and skilled masons, significantly accelerating project timelines.

Lead Time and Order Fulfillment:

Our streamlined manufacturing processes and robust supply chain enable efficient order fulfillment. For standard orders of gabion cages for sale, our typical lead time is between 2 to 4 weeks from confirmed order to dispatch, subject to the volume and specific customization requirements. For time-sensitive projects or large-scale procurements, we engage directly with clients to establish expedited production and optimized logistics schedules, ensuring prompt and reliable delivery. Continuous communication throughout the fulfillment process keeps clients informed at every stage.

Comprehensive Warranty Commitments:

We have utmost confidence in the quality and durability of our gabion box products. All hot-dip galvanized gabions are backed by a comprehensive 10-year warranty against manufacturing defects and premature coating failure under normal operating conditions. Our advanced Galfan and PVC-coated gabions carry an extended 20-year warranty, reflecting their superior corrosion resistance and enhanced longevity in demanding environments. Detailed warranty terms and conditions are provided with every quotation and order.

Dedicated Customer Support and Technical Assistance:

Our commitment to client success extends well beyond product delivery. Our team of highly skilled customer support specialists and experienced technical engineers provides unparalleled assistance throughout the entire project lifecycle, including:

- Pre-Sales Technical Consultation: Expert guidance on material selection, design optimization, specification compliance, and value engineering to meet project-specific requirements and budget constraints.

- Detailed Installation Guidance: Provision of comprehensive assembly instructions, best practice recommendations, and on-site technical support (where feasible) to ensure correct and efficient installation.

- Responsive After-Sales Service: Prompt and efficient resolution of any product-related queries, concerns, or technical challenges that may arise post-delivery or during the operational phase.

Our objective is to ensure that our clients not only acquire premium gabion products but also benefit from a partnership that delivers comprehensive support and expertise, contributing to the successful realization of their engineering projects.

Conclusion

Gabion solutions stand as a highly effective, adaptable, and environmentally responsible approach to tackling a diverse array of civil engineering, hydraulic, and environmental challenges. Their inherent flexibility, free-draining nature, exceptional durability, and compelling cost-effectiveness position them as a superior choice for projects demanding robust erosion control, resilient retaining structures, and aesthetically integrated landscape elements. As a dedicated and experienced gabion box supplier, our unwavering commitment to rigorous manufacturing processes, strict adherence to international quality standards, and continuous product innovation ensures that our clients receive solutions of unparalleled quality, reliability, and performance. By thoroughly understanding the intricate technical specifications, leveraging our bespoke customization capabilities, and benefiting from our comprehensive support services, B2B decision-makers and engineering professionals can confidently integrate advanced gabion technology into their most demanding and complex projects. The escalating global emphasis on resilient and sustainable infrastructure development will undoubtedly continue to solidify the position of high-quality gabion cages for sale as a preferred and essential engineering solution worldwide.

References

- ASTM International. "A975/A975M-17, Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses (Metallic-Coated Steel Wire or Metallic-Coated Steel Wire With PVC Coating)." ASTM Standards.

- International Organization for Standardization. "ISO 9001:2015 Quality management systems — Requirements."

- European Committee for Standardization. "EN 10223-3: Steel wire and wire products for fencing and netting - Part 3: Steel wire mesh products for gabions."

- Maccaferri. "Gabion and Reno Mattress Technical Guide." (An industry-standard publication providing design and application guidance for gabion structures).

- Federal Highway Administration (FHWA). "Hydraulic Engineering Circular No. 23 (HEC-23): Bridge Scour and Stream Instability Countermeasures." (Contains extensive guidance on the design and application of gabions in hydraulic engineering).

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025