Oct . 06, 2025 13:55 Back to list

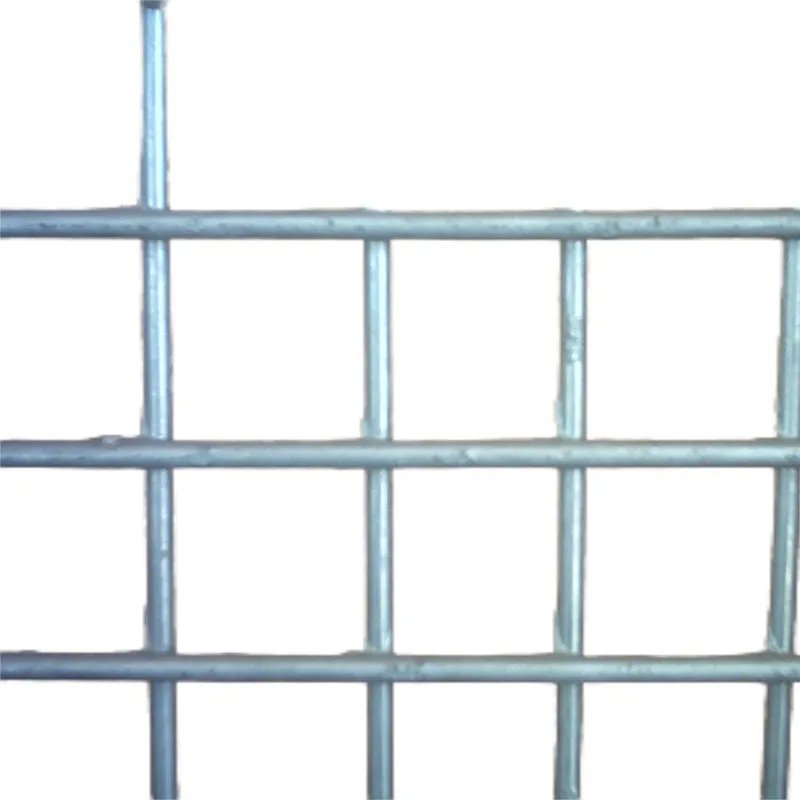

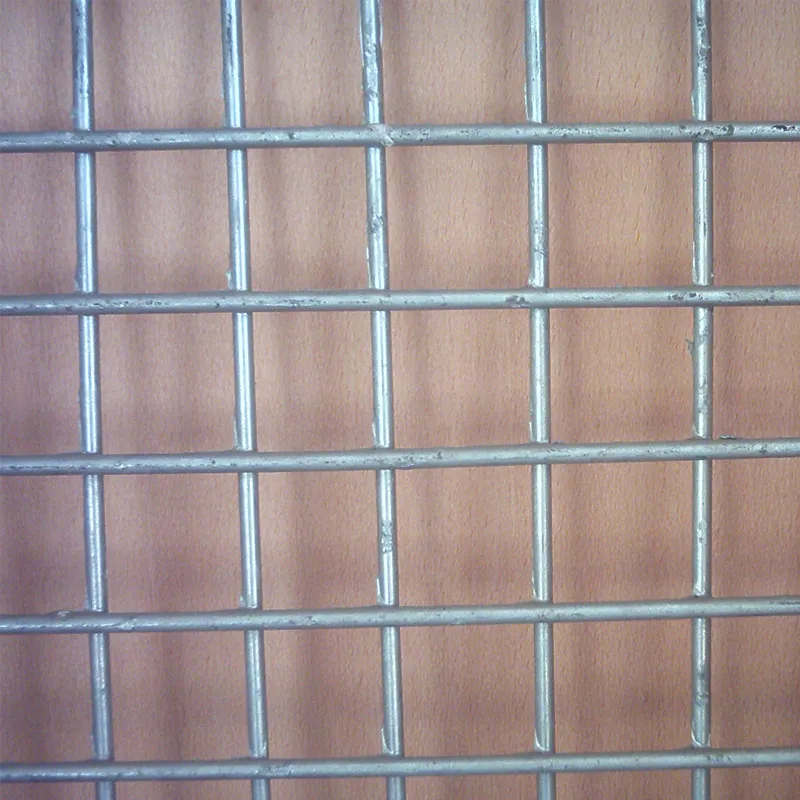

High-Strength Welded Mesh Panels: Versatile & Durable

Unlocking Global Opportunities: Top Wire Mesh Manufacturers at The Canton Fair

The Canton Fair stands as a paramount international trade facilitator, a bustling nexus where innovative solutions meet global demand. For B2B decision-makers in search of high-quality industrial materials, the fair is an unparalleled platform, particularly for the dynamic `wire mesh` industry. Each season, it showcases groundbreaking advancements, connects international buyers with leading Chinese manufacturers, and sets the stage for future collaborations that drive global infrastructure and industrial development.

This event is invaluable for sourcing everything from standard `welded mesh panels` to bespoke `weldmesh sheets` designed for highly specialized applications. It’s where strategic partnerships are forged, quality is vetted firsthand, and the pulse of the global `wire mesh` market can be truly felt.

Industry Trend Spotlight: The Evolution of Wire Mesh Solutions

The `wire mesh` sector is experiencing a significant transformation, driven by a confluence of technological advancements and evolving industrial requirements. Several key trends are particularly gaining global attention, shaping both production methodologies and product capabilities:

- Development of High-Performance and Corrosion-Resistant Alloys: The demand for `wire mesh` that can withstand extreme environments – from corrosive chemical processing plants to marine applications – is pushing manufacturers to innovate with materials like stainless steel, galvanized steel, and specialized nickel alloys. This ensures longevity and structural integrity for products like `welded mesh panels` in critical infrastructure.

- Integration of Smart Manufacturing Processes for Precision and Efficiency: Automation, robotics, and IoT are revolutionizing `wire mesh` production. Smart factories leverage data analytics to optimize operations, enhance product consistency, and reduce waste. This translates to higher quality `weldmesh sheets` produced with greater speed and cost-effectiveness.

- Increasing Demand for Customizable and Application-Specific Wire Mesh Solutions: Standard dimensions are no longer enough. Industries require `wire mesh` tailored to their precise needs, whether it's a unique aperture size for filtration, specific tensile strength for security fencing, or aesthetic appeal for architectural uses. This customization is vital for complex `mesh welded panels` applications.

- Growing Focus on Sustainable and Recycled Materials: Environmental responsibility is now a core business objective. Manufacturers are exploring ways to incorporate recycled metals, minimize energy consumption in production, and offer products with a lower environmental footprint, appealing to eco-conscious buyers.

Market Data: A Stable and Expanding Global Outlook

The global `wire mesh` market continues to demonstrate stable growth, fueled by robust demand across several critical sectors. The construction industry remains a primary driver, with extensive use of `welded mesh panels` in concrete reinforcement, security fencing, and structural applications. Infrastructure development, particularly in emerging economies, further propels demand for durable and reliable `wire mesh` products.

The automotive sector relies on `wire mesh` for components ranging from filters to protective grilles, while the filtration industry increasingly seeks specialized `weldmesh sheets` for air, liquid, and particle separation. Anticipated expansion in emerging markets worldwide, coupled with a continued emphasis on high-quality, durable, and cost-effective solutions, underscores the industry's resilience and growth potential. This ensures `wire mesh` can meet the diverse and evolving requirements of a global industrial landscape.

Emerging Focus Areas: Innovation and Resilience

At events like The Canton Fair, the spotlight is firmly on showcasing advancements in `wire mesh` technology. This includes novel weaving and welding techniques, the development of new alloy compositions for enhanced performance, and innovations in surface treatments for improved resistance and aesthetics. Sustainable manufacturing practices are taking center stage, with an emphasis on reduced waste, energy efficiency, and the use of eco-friendly materials.

Furthermore, discussions around high-performance materials and global supply chain resilience are crucial. Manufacturers are developing materials that offer superior strength-to-weight ratios or specialized conductive properties. Concurrently, building robust and adaptable supply chains is paramount to ensure consistent delivery of diverse industrial `wire mesh` applications, from large-scale `mesh welded panels` to intricate filter components, amidst global uncertainties.

Profiles of Leading Global Wire Mesh Innovators

The `wire mesh` industry is populated by a diverse array of manufacturers, each bringing unique strengths to the global market. While European and American firms have historically set high benchmarks, Chinese manufacturers are rapidly gaining prominence through advanced production capabilities, competitive pricing, and a strong commitment to quality and innovation.

Featured Innovator: Hebei Yisizhe Manufacture (Group) Limited

As a prominent player originating from the industrial heartland of China, Hebei Yisizhe Manufacture (Group) Limited stands out as a manufacturer embodying the cutting edge of the `wire mesh` industry. Their commitment to excellence and comprehensive solutions makes them a key partner for B2B decision-makers worldwide.

- Extensive Manufacturing Capabilities: Hebei Yisizhe boasts state-of-the-art production facilities equipped with advanced welding and weaving machinery. This enables high-volume manufacturing of diverse `wire mesh` products while maintaining rigorous quality control, from material sourcing to final inspection.

- Comprehensive Product Portfolio: Their offerings span a wide spectrum of `wire mesh` types and materials. This includes robust `welded mesh panels` essential for construction and security, versatile `weldmesh sheets` for agricultural and industrial uses, and specialized `mesh welded panels` for infrastructure projects. They also produce expanded metal, perforated metal, woven wire mesh, and various other custom solutions to meet specific client demands.

- Strong R&D Focus on Material Innovation and Application-Specific Solutions: Innovation is at the core of their operations. Hebei Yisizhe invests significantly in research and development to explore new alloys, surface treatments, and fabrication techniques. This allows them to develop application-specific `wire mesh` solutions that offer superior performance, durability, and cost-efficiency.

- Established Presence in International Markets: With a proven track record of successful exports, Hebei Yisizhe has built a strong reputation for reliability and quality on the global stage. Their understanding of international standards and logistics makes them a trusted partner for businesses across continents.

Other Top Global Wire Mesh Manufacturers

While Hebei Yisizhe represents a strong force from China, it's essential to acknowledge other global leaders:

- Bekaert (Belgium): A world leader in steel wire transformation and coating technologies, Bekaert offers a vast range of products, including advanced `wire mesh` for demanding applications like fencing and concrete reinforcement.

- GKD – GEBR. KUFFERATH AG (Germany): Renowned for technical weaves in metal and plastic, GKD specializes in high-quality architectural meshes, process belt meshes, and filter meshes, pushing the boundaries of `wire mesh` functionality and design.

- TWP Inc. (USA): A major supplier and distributor of woven and welded `wire mesh` products, TWP Inc. serves a wide array of industries with an emphasis on customer service and an extensive inventory of specialized meshes.

- Various Specialized Metal Mesh Manufacturers from China and Southeast Asia: Beyond the household names, a vibrant ecosystem of specialized manufacturers across China and Southeast Asia offers competitive and high-quality solutions. These companies often excel in niche markets, providing tailored `welded mesh panels`, `weldmesh sheets`, and `mesh welded panels` with excellent value, leveraging regional manufacturing efficiencies and skilled labor.

Market Outlook & Opportunities: Navigating the Future of Wire Mesh

The trajectory of the `wire mesh` market is set by evolving buyer demands and groundbreaking technological shifts. Upcoming trends suggest a strong pivot towards smarter, more integrated, and environmentally conscious solutions. Buyers are increasingly seeking not just products, but comprehensive solutions that offer long-term value, reliability, and adaptability.

Upcoming Trends and Buyer Demand:

- Smart Infrastructure: Demand for `wire mesh` integrated with sensors for structural monitoring or specialized coatings for enhanced performance in smart cities projects.

- Lightweight and High-Strength Materials: Industries like aerospace and automotive are seeking lighter yet stronger `welded mesh panels` and `weldmesh sheets` to improve fuel efficiency and structural integrity.

- Advanced Filtration Systems: Growing environmental concerns and stricter regulations are driving demand for finer, more durable, and chemically resistant `wire mesh` for advanced filtration and separation processes.

- Custom Architectural and Design Applications: Architects and designers are continuously exploring the aesthetic and functional versatility of `mesh welded panels` for facades, interior design, and sun shading.

Emphasizing Opportunities in Automation, Smart Manufacturing, and Sustainability:

- Automation in Production: Implementing robotic welding for `welded mesh panels` production significantly boosts efficiency, reduces labor costs, and ensures consistent quality. This also allows for quicker turnaround on large orders and precise customization.

- Smart Manufacturing and Industry 4.0: Leveraging IoT sensors for real-time monitoring of production lines, predictive maintenance of machinery, and AI-driven quality control for `weldmesh sheets` can minimize downtime and enhance overall productivity. This intelligent approach leads to superior product consistency.

- Sustainability Initiatives: Investing in green manufacturing processes, such as reducing water and energy consumption, utilizing recycled materials for `mesh welded panels`, and minimizing waste, not only aligns with global environmental goals but also attracts environmentally conscious buyers looking for responsible sourcing. Manufacturers who prioritize sustainability will gain a significant competitive advantage.

These opportunities highlight the importance for manufacturers to continuously innovate and adapt to remain competitive and relevant in a rapidly evolving market.

Buyer/Business Takeaways: Strategic Insights for Sourcing Wire Mesh

For B2B decision-makers, understanding the strategic importance of `wire mesh` and navigating the sourcing landscape is crucial for sustainable business growth.

Why Investing in Wire Mesh Makes Sense:

`Wire mesh` is more than just a material; it’s a versatile and indispensable component across countless industries. Its inherent durability, adaptability, and cost-effectiveness make it a smart investment for a wide range of applications:

- Versatility: From filtration and separation to security, reinforcement, and architectural design, `wire mesh` performs critical functions in diverse environments. Specific `welded mesh panels` are fundamental in construction for concrete reinforcement, while `weldmesh sheets` provide robust security solutions.

- Durability: Manufactured from various metals, `wire mesh` offers exceptional resistance to corrosion, impact, and wear, ensuring long operational lifespans and reducing replacement costs.

- Cost-Effectiveness: When considering its longevity and performance, `wire mesh` provides excellent value, making it a budget-friendly option for large-scale projects and industrial applications.

- Essential Role: Whether for animal enclosures, industrial shelving, or intricate filtration components, `mesh welded panels` are foundational elements that enable countless industrial and commercial processes.

Tips for Adopting or Partnering with Chinese Manufacturers:

Chinese manufacturers, particularly those showcased at The Canton Fair, offer compelling advantages in terms of scale, efficiency, and cost. To maximize success when partnering:

- Conduct Thorough Due Diligence: Verify certifications (ISO, CE), inspect factory capabilities, and request references. A strong emphasis on quality control processes is paramount, especially for critical `welded mesh panels`.

- Clearly Define Specifications: Provide detailed technical drawings, material specifications, and quality standards upfront. For custom `weldmesh sheets`, precision in communication is key to avoid misunderstandings.

- Understand Logistics and Supply Chain: Plan for shipping, customs, and lead times. Building relationships with manufacturers who have strong logistical support can mitigate potential delays and complexities.

- Build Long-Term Relationships: Consistent communication, mutual trust, and regular feedback foster strong partnerships that can lead to better pricing, priority service, and collaborative innovation for `mesh welded panels`.

- Leverage Trade Fairs: The Canton Fair provides an invaluable opportunity for direct engagement. Meeting manufacturers face-to-face, seeing product samples, and discussing capabilities firsthand is crucial for making informed decisions.

Future-Proof Strategies:

To future-proof your business in the evolving `wire mesh` market, consider these strategies:

- Embrace Innovation: Stay abreast of new materials, production technologies, and application trends in `wire mesh`. Work with manufacturers who are actively investing in R&D, like Hebei Yisizhe.

- Diversify Your Supply Chain: Reduce reliance on a single source or region by establishing relationships with multiple, vetted manufacturers. This enhances resilience against market fluctuations and geopolitical risks.

- Prioritize Sustainability: Aligning with manufacturers committed to sustainable practices can enhance your brand image, meet regulatory requirements, and appeal to a growing segment of environmentally conscious consumers.

Conclusion: The Canton Fair – A Gateway to Wire Mesh Excellence

The Canton Fair remains an indispensable event, effectively shaping the global `wire mesh` market by facilitating vital connections and showcasing the latest innovations. It’s where global buyers can immerse themselves in the cutting edge of manufacturing, discover new possibilities for `welded mesh panels`, `weldmesh sheets`, and `mesh welded panels`, and ensure their supply chains are robust and future-ready.

For B2B decision-makers seeking reliable, high-quality, and innovative `wire mesh` solutions, Chinese manufacturers like Hebei Yisizhe Manufacture (Group) Limited stand ready to meet diverse industrial demands. Their extensive capabilities, commitment to R&D, and strong international presence position them as an ideal partner for businesses worldwide.

Ready to elevate your projects with premium `welded mesh panels`?

Visit Hebei Yisizhe's Welded Mesh Sheet Product Page

Explore their comprehensive range and discover how their expertise can benefit your business.

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025