Sep . 22, 2025 13:40 Back to list

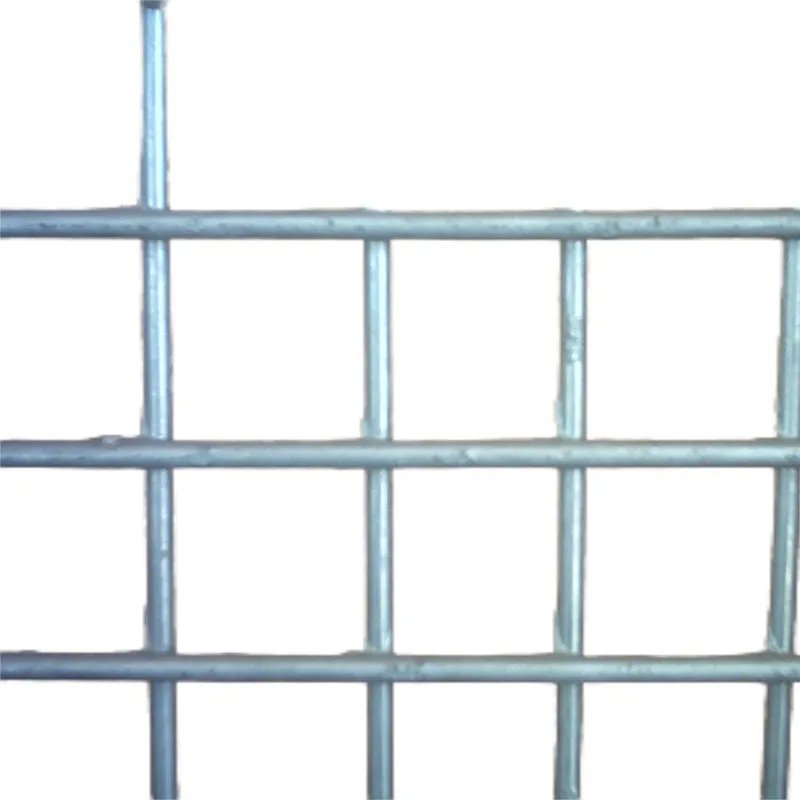

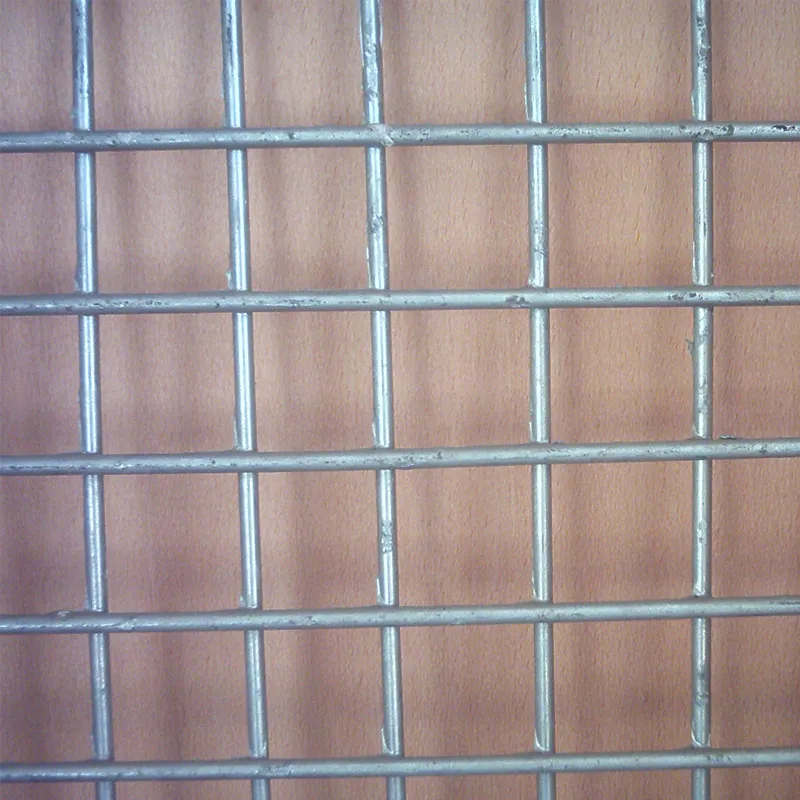

High-Strength Welded Mesh Panels - Durable & Versatile

The Indispensable Role of Welded Mesh Panels in Modern Industrial Infrastructure

In the realm of B2B infrastructure and industrial applications, the demand for robust, versatile, and cost-effective material solutions is ever-present. Among these, welded mesh panels stand out as a foundational component, offering unparalleled structural integrity and adaptability. These engineered sheets, characterized by their precisely welded intersections of intersecting wires, provide superior strength and uniform aperture, making them ideal for a myriad of demanding environments. From construction and security to agriculture and advanced manufacturing, their utility is broad, underpinning critical operations with reliability and efficiency.

This comprehensive analysis delves into the technical intricacies, application diversity, and strategic advantages of these crucial industrial materials, equipping B2B decision-makers with the insights needed to optimize their procurement and deployment strategies.

Industry Trends and Market Dynamics for Welded Mesh Solutions

The global market for welded mesh panels is experiencing steady growth, driven by burgeoning infrastructure projects, increased industrialization in developing economies, and a heightened focus on safety and security across sectors. Key trends include:

- Sustainability & Eco-friendly Materials: A rising demand for materials with reduced environmental impact, including options made from recycled steel and processes that minimize energy consumption.

- Advanced Coatings: Innovations in protective coatings, such as advanced PVC, epoxy, and specialized galvanization techniques, are extending product lifespan and performance in harsh conditions, particularly for weldmesh sheets used outdoors or in corrosive environments.

- Customization & Automation: Increased need for tailor-made mesh configurations, sizes, and wire diameters, facilitated by advanced automated manufacturing processes that allow for high precision and efficiency.

- Smart Infrastructure Integration: Emerging applications where mesh panels are integrated with sensing technologies for real-time monitoring of structural integrity or security breaches.

- Modular Construction: The shift towards prefabricated and modular construction methods boosts demand for standardized yet adaptable mesh panel sizes.

According to recent industry reports, the global welded wire mesh market is projected to reach USD 5.5 billion by 2028, growing at a CAGR of over 4.5% from 2023 to 2028, underscoring the vital and expanding role of these products in industrial development.

Detailed Manufacturing Process Flow of Welded Mesh Panels

The production of high-quality welded mesh panels is a meticulous process involving several critical stages to ensure structural integrity and dimensional accuracy. The typical manufacturing flow is as follows:

1. Material Selection and Preparation

The process begins with the selection of high-grade raw materials, primarily steel wire. Common materials include low-carbon steel, galvanized steel, stainless steel (e.g., SS304, SS316), and sometimes high-tensile steel. These materials are chosen based on the intended application's requirements for strength, corrosion resistance, and ductility. The selected wire coils undergo rigorous inspection to ensure adherence to material specifications like ASTM A641 for galvanized wire or ASTM A276 for stainless steel.

2. Wire Straightening and Cutting

Coiled wires are fed into automatic straightening and cutting machines. These machines precisely straighten the wire and cut it into pre-determined lengths, forming both longitudinal (line) wires and transversal (cross) wires. This step is critical for ensuring the uniform dimensions and flatness of the final mesh welded panels.

3. Automated Resistance Welding

The core of the manufacturing process involves precision resistance welding. Longitudinal wires are fed continuously through an automated welding machine, while transversal wires are fed intermittently from a hopper. At each intersection, powerful electrical currents are passed through the wires, generating intense heat and pressure that fuse them together to form a robust, permanent joint. Modern CNC-controlled welding machines ensure consistent mesh openings and precise weld strength, adhering to standards like AWS D1.1 (Structural Welding Code – Steel) for weld quality.

4. Finishing and Surface Treatment

After welding, panels may undergo various finishing processes to enhance their durability, aesthetics, and corrosion resistance. Common treatments include:

- Hot-dip Galvanizing: Panels are immersed in molten zinc, creating a metallurgical bond that provides excellent long-term corrosion protection, often conforming to ISO 1461 or ASTM A123.

- Electro-galvanizing: A thinner zinc coating offering moderate corrosion resistance.

- PVC/Powder Coating: A layer of polymer or epoxy is applied, offering superior corrosion resistance, UV protection, and a wide range of color options for aesthetic or identification purposes.

- Pickling and Passivation: For stainless steel panels, these processes remove contaminants and enhance the passive layer, improving corrosion resistance.

5. Quality Control and Testing

Each batch of welded mesh panels undergoes stringent quality control. Testing includes:

- Weld Shear Strength Test: To ensure the integrity of the welded joints.

- Dimensional Accuracy Check: Verification of mesh opening, wire diameter, and panel dimensions.

- Coating Thickness Measurement: For galvanized or coated panels, ensuring protective layers meet specifications.

- Material Composition Analysis: Confirming raw material compliance.

Adherence to international standards such as ISO 9001 for quality management and specific product standards like ASTM A185/A185M for Steel Welded Wire Reinforcement, Plain, for Concrete ensures consistent product quality and reliability across target industries like petrochemical, metallurgy, water supply & drainage, and construction. The typical service life of properly treated welded mesh panels can range from 15-20 years for galvanized options to 25+ years for stainless steel or heavy PVC-coated variants in moderate environments, demonstrating significant advantages in corrosion resistance and long-term cost-effectiveness.

Technical Specifications and Parameters

Understanding the technical specifications of welded mesh panels is crucial for proper selection and application. Key parameters directly influence performance, load-bearing capacity, and suitability for specific environments. Below is a representative table of common product specifications for high-quality welded mesh sheets:

These specifications are crucial for architects, engineers, and procurement specialists to ensure the selected mesh meets the exact structural, environmental, and safety requirements of their projects. For instance, a finer mesh opening might be critical for filtration or pest control, while a larger wire diameter is essential for load-bearing applications like shelving or reinforcement.

Technical Advantages of Welded Mesh Panels

The widespread adoption of welded mesh panels across diverse industries is largely attributable to their inherent technical advantages:

- Superior Structural Integrity: The precision resistance welding at each intersection creates a rigid, integral structure, preventing individual wires from shifting or unraveling, unlike woven mesh. This provides higher shear strength and dimensional stability.

- High Strength-to-Weight Ratio: By optimizing wire diameter and mesh opening, these panels offer significant strength and load-bearing capabilities while remaining relatively lightweight, facilitating easier handling and reducing structural loads.

- Enhanced Corrosion Resistance: With options for hot-dip galvanization, electro-galvanization, PVC, or powder coating, panels can be tailored to withstand severe corrosive environments, from marine applications to chemical processing plants. This significantly extends service life and reduces maintenance costs.

- Ease of Fabrication and Installation: Their rigid, planar form makes them easy to cut, bend (with appropriate tools), and integrate into various structures. This streamlines installation, reducing labor costs and project timelines.

- Uniform Mesh Openings: The automated welding process ensures consistent and precise apertures, critical for applications requiring controlled filtration, security, or aesthetic uniformity.

- Versatility: Available in a vast array of materials, wire diameters, and mesh sizes, they can be customized for specific load requirements, environmental conditions, and aesthetic preferences.

These advantages collectively translate into a compelling value proposition for industrial and commercial projects, offering long-term reliability and operational efficiency.

Application Scenarios and Target Industries

The adaptability of welded mesh panels makes them indispensable across a wide spectrum of industries. Their application scenarios are as diverse as the panel configurations themselves:

- Construction & Civil Engineering:

- Concrete Reinforcement: Welded wire mesh is widely used as reinforcement in concrete slabs, foundations, and precast elements, preventing cracking and enhancing structural integrity (e.g., meeting ASTM A1064/A1064M for steel wire mesh for concrete reinforcement).

- Fencing & Perimeter Security: High-security fencing for industrial facilities, prisons, and infrastructure projects, offering robust anti-climb and anti-cut properties.

- Gabion Baskets: Used in civil engineering for retaining walls, erosion control, and landscaping, providing structural stability.

- Petrochemical & Energy:

- Safety Barriers & Machine Guards: Protecting personnel from moving machinery and hazardous areas in refineries and power plants.

- Filtration & Screening: Stainless steel mesh used in high-temperature or corrosive filtration systems for gases and liquids.

- Metallurgy & Mining:

- Mine Support Systems: Reinforcing tunnel walls and ceilings to prevent rockfalls.

- Screens & Sieves: For separating and classifying ore, aggregates, and other raw materials.

- Water Supply & Drainage:

- Drainage Grates & Covers: Durable and robust solutions for water runoff management in public and industrial areas.

- Water Treatment Facilities: Used in various stages of filtration and sediment removal.

- Agriculture & Horticulture:

- Animal Enclosures: Strong and secure housing for livestock and poultry.

- Trellising & Support Structures: For vertical farming and crop support, ensuring efficient use of space and plant health.

In typical application scenarios, such as perimeter fencing for a data center, the high rigidity and anti-cut properties of a PVC-coated weldmesh sheets contribute to superior energy saving by preventing unauthorized access, thus avoiding potential downtime or security breaches that lead to significant energy consumption for recovery. The corrosion resistance ensures a minimal maintenance footprint over decades, directly impacting operational expenditure favorably.

Vendor Comparison for Welded Mesh Panels

Selecting the right vendor for mesh welded panels is paramount to project success, directly impacting quality, cost, lead time, and overall project efficiency. A robust vendor comparison involves evaluating several critical factors:

Prospective clients should prioritize vendors with a proven track record, extensive industry experience (e.g., 20+ years in service), and transparent adherence to international quality standards. Checking client testimonials, partner clients, and demonstrable case studies offers valuable insights into a vendor's reliability and expertise.

Customized Solutions for Welded Mesh Panels

While standard sizes and materials for welded mesh panels address many needs, specialized projects often demand tailor-made solutions. Leading manufacturers provide extensive customization options to precisely match unique project specifications, optimizing performance and integration. This includes:

- Specific Dimensions: Custom panel widths and lengths, cut-outs, or intricate shapes to fit non-standard structures or equipment enclosures.

- Varied Wire Diameters and Mesh Openings: Precise control over wire gauge and aperture size to meet specific filtration, security, or load-bearing requirements, such as ultra-fine mesh for insect screening or heavy-gauge mesh for high-security applications.

- Specialized Materials: Beyond standard steel, options include exotic alloys for extreme temperatures or highly corrosive environments, or architectural-grade stainless steel for aesthetic prominence.

- Advanced Coatings and Finishes: Custom color matching for PVC or powder coatings to integrate with brand aesthetics or environmental requirements, alongside specialized anti-graffiti or anti-microbial coatings.

- Integrated Features: Pre-attached mounting brackets, specialized edging, or integrated features for ease of installation and enhanced functionality.

Working with a manufacturer capable of advanced customization ensures optimal product fit, reduces on-site modification costs, and enhances the overall efficiency and lifespan of the deployed solution.

Application Case Studies

Real-world applications underscore the effectiveness and versatility of welded mesh panels in addressing complex industrial challenges:

Case Study 1: High-Security Perimeter for a Data Center

Client: Global Cloud Services Provider, Frankfurt, Germany

Challenge: The client required a robust, anti-climb, and anti-cut perimeter security fence for a new data center, capable of withstanding extreme weather and deterring sophisticated intrusion attempts while maintaining a professional aesthetic.

Solution: Customized hot-dip galvanized and then black PVC-coated mesh welded panels with a small aperture (12.7mm x 76.2mm) and heavy wire gauge (4mm). The panels were engineered for superior rigidity and resistance to cutting tools. Each panel was securely bolted to heavy-duty steel posts, featuring razor wire toppers and integrated CCTV mounting points. The PVC coating provided enhanced corrosion resistance and a sleek, modern finish.

Outcome: The installation provided a highly effective, maintenance-free security barrier that exceeded the client's stringent security protocols. The corrosion resistance ensures a service life exceeding 25 years, significantly reducing long-term replacement and maintenance costs, while the aesthetic integration received positive feedback.

Case Study 2: Industrial Flooring and Catwalks in a Chemical Plant

Client: Large-scale Chemical Manufacturer, Houston, USA

Challenge: The plant needed durable, corrosion-resistant flooring and catwalks for areas exposed to various chemical vapors and occasional spills, requiring excellent drainage and anti-slip properties for worker safety.

Solution: Stainless steel welded mesh panels (SS316 grade) with specific load-bearing capabilities and large, uniform mesh openings for optimal drainage. The panels were electropolished and passivated to enhance their inherent corrosion resistance against aggressive chemical agents. Edges were reinforced, and custom clips were designed for secure attachment to structural beams.

Outcome: The installed mesh panels provided a safe, non-slip, and highly durable walking surface that effectively managed liquid spills and facilitated rapid cleaning. The SS316 material choice ensured excellent resistance to the chemical environment, significantly extending the lifespan compared to traditional galvanized options and contributing to a safer operational environment with minimal maintenance downtime.

Quality Assurance and Certifications

Commitment to quality is foundational for reliable welded mesh panels. Reputable manufacturers adhere to stringent quality management systems and hold key certifications demonstrating their compliance with international standards. These often include:

- ISO 9001:2015 Certification: Ensuring a consistent, repeatable manufacturing process that meets customer and regulatory requirements for product quality.

- CE Marking: For products sold within the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- ASTM Standards: Compliance with American Society for Testing and Materials standards relevant to steel wire, galvanization, and concrete reinforcement.

- Internal Quality Control: Rigorous in-house testing protocols covering material composition, weld strength, dimensional accuracy, and coating integrity.

Choosing suppliers with verified certifications and a transparent quality assurance process ensures the longevity, performance, and safety of the mesh panels in their intended applications.

Trustworthiness: FAQ, Lead Time, Warranty, and Support

A reliable partnership extends beyond product delivery to encompass transparent communication, robust support, and clear commitments.

Frequently Asked Questions (FAQ)

Q: What is the typical lead time for custom welded mesh panels?

A: Lead times vary based on complexity, material availability, and order volume. Standard panels can often be dispatched within 1-2 weeks, while highly customized orders may require 3-5 weeks from design confirmation to production completion. Expedited services may be available upon request.

Q: What warranty is provided with your weldmesh sheets?

A: We offer a standard 10-year warranty on material and weld integrity for our hot-dip galvanized and stainless steel panels, provided they are installed and maintained according to specifications. PVC-coated products typically carry a 5-year warranty against significant fading or cracking under normal conditions. Detailed warranty terms are provided with each quotation.

Q: Can you provide installation guidance or technical drawings?

A: Absolutely. Our engineering team provides comprehensive technical drawings, load-bearing calculations, and installation guides upon request. We can also offer consultancy for complex installation scenarios.

Lead Time and Fulfillment

Our production facilities are equipped with state-of-the-art machinery enabling efficient manufacturing and rigorous quality control. We maintain strategic inventory levels for common wire types and sizes to expedite orders. Our logistics team works with trusted carriers to ensure timely and secure delivery to project sites globally. Clients receive regular updates on order status, from production milestones to shipping notifications.

Warranty Commitments

We stand by the quality and durability of our welded mesh panels. Our comprehensive warranty covers manufacturing defects and material failures under normal operating conditions. This commitment reflects our confidence in our products and provides peace of mind for our clients, ensuring long-term performance and minimizing lifecycle costs.

Customer Support

Our dedicated customer support team is available to assist with inquiries, technical specifications, order tracking, and any post-sales assistance. We offer multi-channel support via phone, email, and a dedicated online portal. Our goal is to foster long-term partnerships through responsiveness and reliable service.

Conclusion

The enduring appeal of welded mesh panels in B2B environments stems from their potent combination of structural integrity, material versatility, and cost-effectiveness. As industrial sectors continue to evolve, demanding more robust, secure, and sustainable solutions, the role of these panels is set to expand further. By understanding the detailed manufacturing processes, technical advantages, diverse applications, and critical vendor selection criteria, businesses can make informed decisions that optimize project outcomes, ensure long-term reliability, and drive operational excellence. Partnering with a reputable manufacturer committed to quality, customization, and comprehensive support is key to harnessing the full potential of these indispensable industrial components.

References

- ASTM International. (2022). ASTM A1064/A1064M-22: Standard Specification for Steel Welded Wire Reinforcement, Plain and Deformed, for Concrete. ASTM International.

- International Organization for Standardization. (2015). ISO 9001:2015: Quality management systems – Requirements. ISO.

- American Welding Society. (2020). AWS D1.1/D1.1M:2020: Structural Welding Code – Steel. AWS.

- Grand View Research. (2023). Welded Wire Mesh Market Size, Share & Trends Analysis Report.

- Galvanizers Association. (2021). Hot Dip Galvanizing to EN ISO 1461.

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025