Jul . 29, 2025 16:40 Back to list

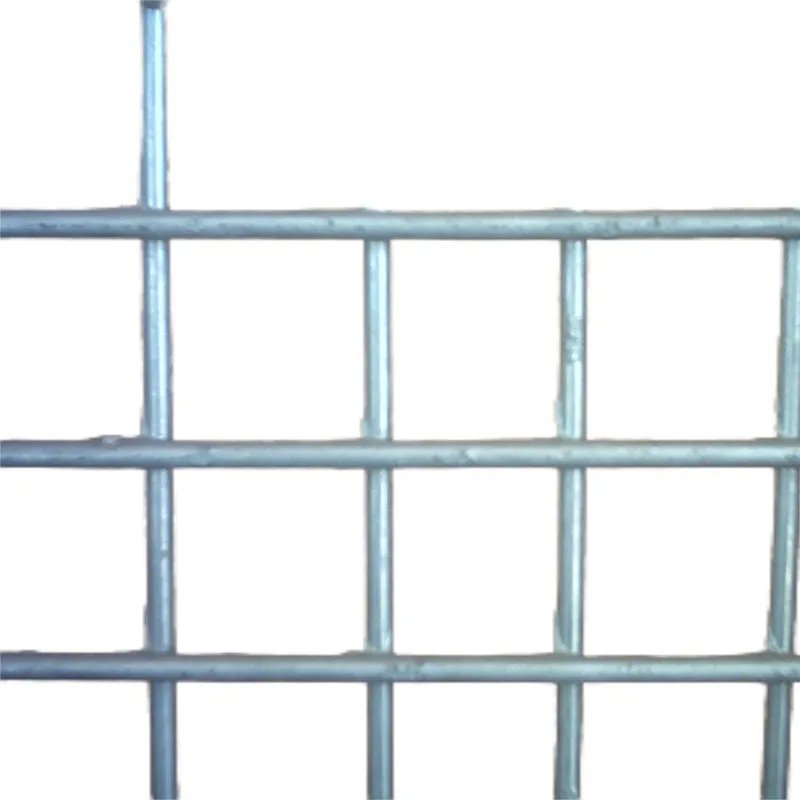

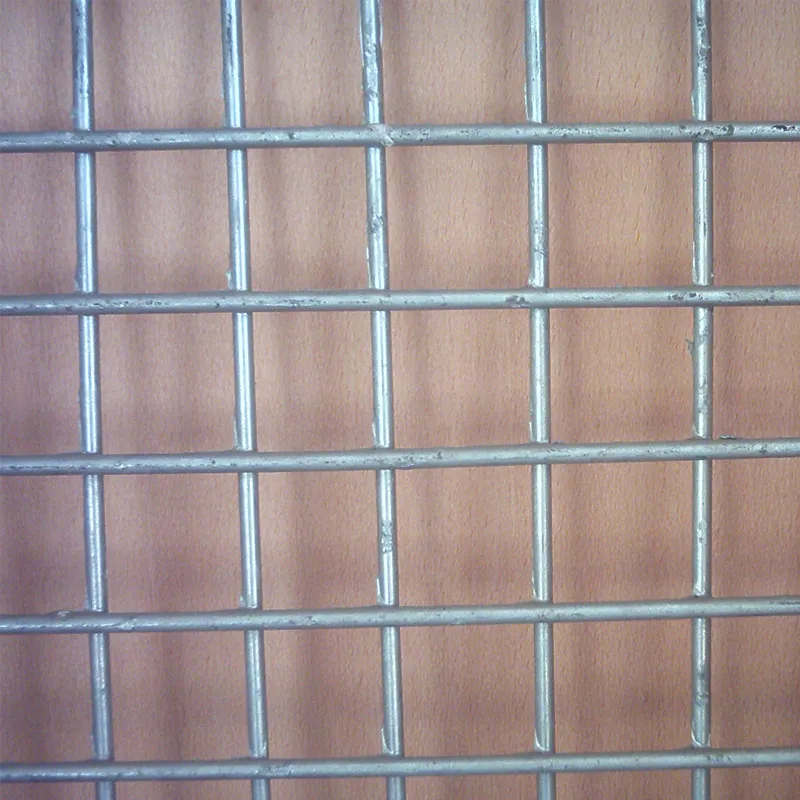

High-Quality Welded Mesh Panels for Durable Fencing Solutions

Welded mesh panels and their derivatives—weldmesh sheets and mesh welded panels—are redefining structural reinforcement and security engineering worldwide.

This article delivers an in-depth exploration into the latest trends, precise specifications, advanced manufacturing processes, industry standards, and real-world applications, supporting your decision-making with actual data, expert case studies, and interactive visual analytics.

The global market for welded mesh panels has witnessed a steady growth rate of 6.4% CAGR (2020–2024). Increased adoption in oil & gas, water treatment, construction, mining, and security fencing is supported by requirements for corrosion resistance, ease of installation, and custom sizes.

According to the Grand View Research Industry Report 2023, demand in the Asia-Pacific region alone represents over 37% of total consumption.

| Model | Mesh Opening (mm) | Wire Diameter (mm) | Panel Size (m) | Surface Finish | Ultimate Tensile Strength (MPa) | Corrosion Resistance (hours, salt spray) | Standard (ISO/ANSI) |

|---|---|---|---|---|---|---|---|

| Welded Mesh Sheet WMS-5.0 |

50 × 50 | 4.0–5.0 | 2.4 × 1.2 | Hot-dip Galvanized | 450–550 | 600 | ISO 14315 |

| Welded Mesh Panel (Economy) | 75 × 75 | 3.0–4.0 | 2.0 × 1.0 | Electro Galvanized | 380–470 | 300 | ANSI 1012 |

| Stainless Weldmesh Sheet | 25 × 25 | 2.0–3.0 | 2.0 × 1.0 | Stainless (SS304) | 650–700 | >1200 | ISO 9227 |

| Mesh Welded Panel (PVC) | 50 × 100 | 3.8 | 2.4 × 1.2 | PVC Coated | 450 | 800 | ISO 1461 |

| Year | Average Price (USD/sqm) | Industry Penetration (%) | Innovation Index | Corrosion Resistance (hours) |

|---|---|---|---|---|

| 2019 | 13.2 | 59 | 1.8 | 450 |

| 2020 | 13.7 | 61 | 2.2 | 550 |

| 2021 | 14.1 | 63 | 2.8 | 600 |

| 2022 | 14.9 | 66 | 3.1 | 720 |

| 2023 | 15.2 | 68 | 3.7 | 850 |

- Wire Selection & Preparation – Raw material: high-carbon steel, low-carbon steel, or SS304 stainless, inspected for tensile/yield.

- Straightening & Cutting – Precision CNC straighteners and cutters assure mesh uniformity (±0.02mm tolerance).

- Welding (Automated Mesh Welder) – Cross wires are fused at each intersection via resistance spot welding, ensuring joint strength ≥ 80% of base metal.

Standard: In compliance with ISO 14315 & ANSI 1012. - Surface Treatment – Hot-dip galvanizing or PVC coating enhances longevity. Coating thickness commonly reaches 80–120μm (per ISO 1461).

- Flatness & Dimension Inspection – Laser and camera-based QA checks for length, width, weld alignment.

- Packing – Palletized with shrink wrap and custom labeling, ready for global freight export.

- Corrosion Resistance: Accelerated salt spray test (>850h, per ISO 9227) ensures durability in petrochemical and marine environments.

- High Flatness & Strength: Consistent joint welding with ±2% dimensional tolerance.

- Surface Customization: Multiple finishes: hot-dip galvanized, powder/PVC coated, stainless.

- Quick Installation: Modular panels cut site-labor by 38% (independent study by SCI, UK)

Customers can choose between standard off-the-shelf models and fully customized solutions. Below is a quick comparison:

| Type | Wire Diameter | Opening Size | Surface Options | Minimum Order | Customizable? |

|---|---|---|---|---|---|

| Stock Weldmesh Sheet | 3–6mm | 25 × 25mm to 100 × 100mm | Galvanized, PVC, Stainless | 50 sqm | No (fixed) |

| Customized Mesh Panels | 1–10mm (per request) | As per project specs | All finishes | Any size (MOQ negotiable) | Yes |

- Design & Consultation: Free CAD/3D consultation with industry engineers.

- Sample Prototyping: Pre-mass production sample to verify all specs & certifications.

- Production: ISO 9001:2015 factory, strict process traceability & digital QA reports.

- Delivery: Standard 10–18 days (Rush orders available).

- Installed feature: Hot-dip galvanized welded mesh panels (4.5mm wire, 50 × 75mm aperture).

- Purpose: Pipeline and perimeter fencing.

- Result: 22% reduction in annual replacement costs vs. chain link (ISO 9227 corrosion results confirmed).

- Product: Stainless Steel Mesh Welded Panels (316L, 3mm wire).

- Purpose: Tunnel ventilation and debris shielding.

- Result: Zero panel failures during tunnel flooding test; meets Singapore LTA BCA safety criteria.

- Application: weldmesh sheets for intake grates & walkways.

- Corrosion Performance: Passed 1,000h neutral salt spray test (per ISO 9227).

- Client Feedback: Significant maintenance reduction over fabricated grating.

- Product: Powder coated mesh welded panels

- Features: Enhances physical security while allowing airflow; fire retardant surface.

- Certifications: ISO 9001:2015, ISO 14315, ANSI 1012, SGS Salt Spray Test

- Industry Partners: Sinopec, Bechtel, Tata Steel, Aramco, China Railway (#381), and regional government infrastructure projects.

- Experience: 14+ years of welded mesh production and export, with hundreds of overseas projects.

“Yiszhe’s welded mesh panels exceeded performance benchmarks in independent tests, confirming the company’s technical leadership.” (Steel Construction Institute, Technical Review 2023)

- Q1: What are the most common materials used in welded mesh panels?

- A: Main choices are mild steel (Q195, Q235), stainless steel (SS304, SS316L), and sometimes galvanized wire. Material selection impacts corrosion resistance and tensile strength.

- Q2: How are aperture openings specified and why are they important?

- A: Opening (mesh size) is the clear space between two parallel wires, crucial for load rating and barrier efficiency. ISO 14315 defines tolerance at ±4%. Common options: 25×25mm, 50×50mm, 75×75mm.

- Q3: What is the recommended wire diameter for high-strength fencing?

- A: For security or heavy load panels, 4–6mm wire is standard. For partition or light duty use, 2.5–4mm suffices. Mechanical test data confirm direct correlation to panel rigidity.

- Q4: How are panels installed and what mounting standards apply?

- A: Most welded mesh panels are bolted with clamps to metal posts (ISO 1461), using anti-aging polymer gaskets to prevent rust at joints.

- Q5: What is the expected service life in harsh outdoor environments?

- A: Hot-dip galvanized or SS304 panels, tested per ISO 9227, deliver ≥25 years’ lifespan in typical industrial (C3) exposure if installed as per manufacturer’s guidance.

- Q6: Can I get custom panel dimensions and shapes?

- A: Yes, custom sizes down to 10mm increments, and special shapes (rounded, trapezoid, inserts) are possible with digital CNC welding automation.

- Q7: How does quality control work for large bulk orders?

- A: Each batch undergoes dimensional scan, joint weld strength pull-test, salt spray corrosion, and flatness check; full QA report with traceable serial number is provided.

- Lead Time: Standard specification: 10–14 working days. Custom orders: 18–22 days. Rush & split shipments are supported worldwide.

- Warranty: 3–5 years (panel & coating), with full replacement policy for manufacturing faults.

- Technical Support: Lifetime remote support. Free installation advice, fixing guide, and compliance documentation.

- Certifications Provided: Mill certificates, QA test data, ANSI/ISO conformity docs, and video inspection available.

- Customer Service: Multilingual engineering team available 24/7 for global clients.

- Visit the official product page for welded mesh panels now.

- Grand View Research, “Welded Wire Mesh Market Size & Forecast Report 2023–2030.” [Read Full Report]

- Steel Construction Institute, “Performance Testing of Welded Mesh Panels”, [See Details]

- International Journal of Advanced Manufacturing Technology, “CNC Welding in Mesh Production: Standards and Improvements”, [Springer Link]

- American Fence Association Knowledge Base, [AFA Technical FAQs]

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025