Sep . 14, 2025 10:00 Back to list

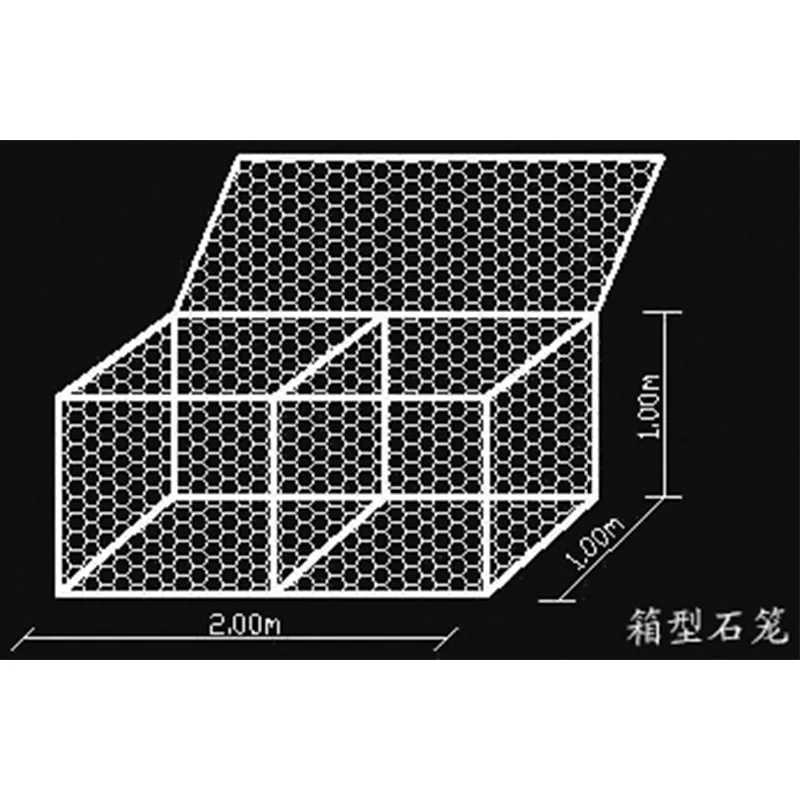

Gabion Cages for Sale - Durable & Affordable Gabion Boxes

Introduction to Gabion Solutions and Industry Trends

The demand for robust and environmentally sustainable civil engineering solutions has propelled gabion technology to the forefront of modern infrastructure development. Gabion structures, essentially wire mesh container111s filled with inert materials such as rock, concrete, or sand, are increasingly being specified for their versatility, durability, and eco-friendly attributes. The global market for gabions is projected to grow significantly, driven by an increased focus on erosion control, retaining wall applications, and resilient construction in areas prone to natural disasters. This growth is particularly notable in regions undergoing rapid urbanization and infrastructure expansion.

Key industry trends indicate a shift towards more advanced coating technologies, such as Galfan (zinc-aluminum alloy) and PVC-coated wire, to extend the service life of structures in corrosive environments. Furthermore, there's a growing preference for factory-assembled or panelized gabion systems that reduce on-site labor and accelerate project timelines. As a leading gabion box supplier, we recognize the critical need for high-quality, reliable, and cost-effective gabion cages for sale that meet stringent international standards.

Technical Specifications of Gabion Boxes

Understanding the technical specifications of gabion components is crucial for ensuring structural integrity and performance. Our gabion box products are engineered to meet and exceed industry benchmarks, offering exceptional strength and durability. The primary components include the wire mesh, which forms the basket, and the lacing wire or C-rings used for assembly. The material composition, mesh aperture, and coating type are paramount in determining the product's suitability for specific applications.

Gabion Box Standard Specifications Table

| Parameter | Description | Standard Range | Relevant Standard |

|---|---|---|---|

| Wire Material | Low carbon steel wire | Conforming to ASTM A975-97 | ASTM A975 |

| Wire Diameter (Mesh) | Thickness of wire used for mesh weaving | 2.0mm - 4.0mm (e.g., 2.7mm, 3.0mm) | EN 10218-2 |

| Wire Diameter (Selvedge) | Thicker wire used for edges and diaphragms | 3.0mm - 4.5mm (typically 0.5-1.0mm thicker than mesh wire) | EN 10218-2 |

| Mesh Type | Double twisted hexagonal mesh | 60x80mm, 80x100mm, 100x120mm | ASTM A975, EN 10223-3 |

| Coating Type | Corrosion protection layer | Hot-dip galvanized, Galfan (Zn-5%Al-MM), PVC coated | ASTM A641, ASTM A975, EN 10244-2 |

| Tensile Strength | Wire resistance to breaking under tension | 350-550 N/mm² | EN 10223-3 |

| Corrosion Resistance | Ability to withstand environmental degradation | Min. 3000-5000 hours salt spray (Galfan), 500 hours (Galvanized) | ASTM B117, ISO 9227 |

The selection of the appropriate gabion type for sale depends on environmental factors, expected service life, and structural requirements. For instance, in highly corrosive marine or industrial environments, PVC-coated gabions offer superior protection, typically extending service life to over 70 years, compared to 20-30 years for standard galvanized options. These specifications ensure that our gabion cages for sale provide long-term performance and reliability.

Manufacturing Process Flow of Gabion Cages

The manufacturing of high-quality gabion cages for sale involves a meticulous multi-stage process, ensuring structural integrity and longevity. Our adherence to international standards like ISO 9001 for quality management and rigorous internal quality control measures guarantees superior products.

Detailed Process Flow:

-

Material Sourcing & Quality Control:

We procure low-carbon steel wire rods from certified suppliers, ensuring compliance with ASTM A975-97 standards for material composition and mechanical properties. Each batch undergoes tensile strength and chemical composition testing upon arrival.

-

Wire Drawing & Annealing:

The steel rods are drawn through dies to achieve the precise wire diameters required for mesh and selvedge wires (e.g., 2.7mm for mesh, 3.4mm for selvedge). An annealing process may be applied to optimize ductility and workability for the subsequent weaving process.

-

Wire Coating (Galvanizing/Galfan/PVC):

- Hot-dip Galvanizing: Wire is immersed in molten zinc, creating a protective zinc layer (min. 240g/m² coating weight per EN 10244-2 Class A). This provides corrosion resistance for standard applications.

- Galfan Coating: A zinc-5% aluminum-mischmetal alloy coating is applied, offering superior corrosion resistance (typically 2-3 times that of conventional galvanizing).

- PVC Coating: For enhanced durability in aggressive environments, galvanized or Galfan-coated wire is further coated with a UV-stabilized PVC layer (min. 0.5mm thickness).

-

Mesh Weaving (Double-Twisted Hexagonal):

Specialized automatic machinery precisely weaves the coated wires into the characteristic double-twisted hexagonal mesh patterns (e.g., 80x100mm). This double-twist ensures that if a wire breaks, the integrity of the mesh is maintained, preventing unraveling.

-

Panel Cutting & Edging:

The woven mesh is cut into panels (front, back, sides, lid, base, diaphragms) according to specified dimensions. Selvedge wires, which are thicker, are then mechanically woven or crimped along all panel edges to reinforce the structure and facilitate assembly.

-

Pre-assembly & Folding:

For ease of transportation and on-site assembly, the panels are either factory-assembled into a collapsed form or supplied as flat packs. Diaphragms are integrated into larger units as per design.

-

Final Inspection & Packaging:

Each gabion unit undergoes a final quality inspection for dimensions, mesh consistency, coating integrity, and overall workmanship. Products are then bundled and packaged securely for shipping, minimizing potential damage during transit. Our service life for standard galvanized gabions typically exceeds 25 years, while Galfan and PVC-coated options can reach 50-70+ years depending on environmental conditions.

Target industries include civil engineering, petrochemical, metallurgy, water supply & drainage, and agricultural sectors, where resilience and environmental compatibility are critical. The inherent flexibility of gabion structures allows them to tolerate differential settlement without loss of structural integrity, a significant advantage in dynamic geological environments.

Application Scenarios and Technical Advantages

The versatility of gabion cages for sale makes them indispensable across a broad spectrum of civil engineering and environmental management applications. Their unique structural and hydraulic properties offer significant advantages over traditional construction materials.

Primary Application Scenarios:

- Retaining Walls: For soil retention on slopes, stabilizing embankments, and terracing landscapes. Gabion walls are flexible, allowing them to settle without cracking, and are free-draining, preventing hydrostatic pressure buildup.

- Erosion Control & Riverbank Protection: Preventing scour and erosion along rivers, canals, and coastlines. Gabions dissipate wave energy and allow vegetation to establish, enhancing ecological integration.

- Weirs and Dams: Constructing low-head weirs for water diversion, energy dissipation, or flow control in waterways.

- Channel Linings: Stabilizing canal and ditch banks to prevent erosion and maintain flow capacity.

- Bridge Abutments & Culverts: Providing robust and flexible support structures for bridge foundations and culvert protection.

- Noise Barriers: When filled with specific aggregate, gabions can effectively absorb sound, making them suitable for noise attenuation along highways or industrial sites.

- Landscaping & Architectural Features: Their aesthetic appeal and ability to blend with natural surroundings make them popular for decorative walls, seating, and garden features.

Technical Advantages:

- Flexibility: Unlike rigid concrete structures, gabion structures can accommodate differential ground settlement without fracturing. This makes them ideal for unstable soil conditions or seismic zones. This is a significant advantage in scenarios such as preventing catastrophic failures in retaining walls along active geological fault lines.

- Permeability & Drainage: The interstitial voids between the fill material allow for excellent drainage, eliminating hydrostatic pressure behind retaining walls, which is a common cause of failure in impermeable structures. This inherent drainage also reduces the need for extensive subsurface drainage systems.

- Durability & Longevity: With proper wire coating (Galfan, PVC), gabions exhibit exceptional corrosion resistance. The rock fill itself is inert and highly durable. As the structure ages, sedimentation and vegetative growth can further enhance its strength and integrate it into the environment, potentially extending the effective service life beyond initial projections.

- Environmental Integration: Gabions blend naturally into the landscape. They support vegetation growth, which can stabilize soil, provide habitat, and improve aesthetics. This "green engineering" approach is particularly valued in ecological restoration projects.

- Cost-Effectiveness: The use of locally sourced fill materials significantly reduces transportation costs. The relatively simple construction method minimizes labor requirements and specialized equipment, contributing to overall project cost savings compared to traditional concrete or masonry solutions.

- Energy Saving: The manufacturing process for gabion wire mesh requires less energy than producing an equivalent volume of concrete or steel, contributing to a lower carbon footprint for projects utilizing our gabion box products.

Vendor Comparison and Customized Solutions

Choosing the right gabion box supplier is critical for project success, impacting material quality, delivery timelines, and overall cost-efficiency. Our commitment to excellence sets us apart in the market for gabion cages for sale.

Gabion Supplier Comparison Matrix

| Feature/Provider | Our Company (Yiszhe Wire Mesh) | Competitor A (General Supplier) | Competitor B (Budget Supplier) |

|---|---|---|---|

| Quality Certifications | ISO 9001, ASTM A975, EN 10223-3 Compliant | Limited (e.g., only local standards) | Often none or unverifiable |

| Wire Coating Options | Hot-dip Galvanized, Galfan, PVC Coated (full range) | Often only standard Galvanized | Thin galvanized, no premium options |

| Customization Capacity | Extensive (mesh size, dimensions, wire gauge, coatings) | Limited to standard sizes | Virtually none, off-the-shelf only |

| Technical Support | Dedicated engineering support, design assistance | Basic product information only | Minimal or non-existent |

| Lead Time (Average) | 7-14 business days (depending on volume/customization) | 10-20 business days | Highly variable, often delayed |

| Warranty | Up to 5 years (manufacturing defects) | 1 year limited | No explicit warranty |

Customized Solutions:

We understand that every project has unique requirements. As a specialized gabion box supplier, we offer comprehensive customization options to ensure our gabion box products perfectly integrate with your design specifications. Our engineering team collaborates closely with clients to develop bespoke solutions, encompassing:

- Non-Standard Dimensions: Production of gabion units in specific lengths, widths, and heights beyond standard offerings to fit unique site constraints.

- Varied Mesh Apertures: Custom mesh sizes to accommodate specific fill materials or aesthetic requirements.

- Specialized Coatings: Beyond standard galvanized, Galfan, and PVC, we can explore other corrosion protection systems for highly aggressive environments.

- Integrated Components: Design and fabrication of gabions with integrated lifting loops, internal partitions, or other specialized features for complex installations.

- Pre-filled or Modular Systems: Options for pre-filled gabions for rapid deployment in suitable logistical scenarios, or modular units designed for enhanced efficiency.

Our 15+ years of experience in the wire mesh industry and a strong portfolio of successful projects position us as a reliable partner for even the most challenging gabion applications.

Application Case Studies

Our gabion cages for sale have been successfully deployed in numerous projects worldwide, demonstrating their efficacy and reliability in diverse environmental and structural challenges. These case studies highlight our commitment to delivering superior gabion box solutions.

Case Study 1: Riverbank Stabilization Project, Southeast Asia

- Challenge: A major river in Southeast Asia experienced severe erosion during monsoon seasons, threatening adjacent agricultural land and local infrastructure. Traditional concrete solutions were deemed too rigid and environmentally disruptive.

- Solution: We supplied over 15,000 cubic meters of Galfan-coated gabion cages for sale (mesh 80x100mm, wire 2.7/3.4mm) for a comprehensive riverbank stabilization project. The gabions were stacked to form a stepped retaining structure, filled with locally sourced river stone.

- Outcome: The project successfully stabilized 5 km of riverbank. The gabions demonstrated excellent flexibility against fluctuating water levels and allowed for natural vegetation growth within the structure, promoting ecological recovery. The Galfan coating ensured a projected service life exceeding 50 years, even in the highly humid and occasionally saline environment. Our client reported a 25% cost saving compared to initial concrete-based estimates.

Case Study 2: Highway Embankment Reinforcement, Mountainous Region

- Challenge: A new highway construction in a mountainous region required significant embankment stabilization to prevent landslides and soil erosion, particularly where steep cuts were made. Seismic activity was also a concern.

- Solution: We provided custom-sized PVC-coated gabion box units, specifically designed to withstand aggressive freeze-thaw cycles and high shear forces. The gabions were integrated with geotextile layers to enhance soil retention and filtration.

- Outcome: The gabion retaining walls performed exceptionally well, providing flexible yet robust support that could absorb ground movements. The PVC coating guaranteed long-term corrosion protection in the harsh mountain climate. The project was completed ahead of schedule due to the ease of gabion assembly and use of local rock fill, further underscoring the efficiency of our gabion box supplier solutions.

Case Study 3: Industrial Site Perimeter Security & Retaining Wall

- Challenge: An industrial facility required a secure perimeter fence that also acted as a retaining wall for a raised platform. The environment included exposure to mild industrial chemicals.

- Solution: We supplied a specialized batch of PVC-coated gabion cages for sale with specific wire tensile strengths and mesh sizes, filled with crushed concrete. The gabions were designed to a height of 3 meters and integrated with security fencing.

- Outcome: The gabion structure provided a highly effective dual-purpose solution, offering both robust soil retention and an impenetrable security barrier. The PVC coating proved resistant to the industrial environment, maintaining structural integrity and aesthetic appeal. Client feedback highlighted the ease of installation and the cost-effectiveness compared to a traditional concrete retaining wall with separate security fencing.

Trustworthiness: FAQ, Lead Time, Warranty & Support

Frequently Asked Questions (FAQ)

Q1: What are the typical lead times for gabion box orders?

A1: Our standard lead time for most gabion box orders is 7-14 business days from order confirmation, depending on volume and customization requirements. For large-scale or highly customized projects, we will provide a detailed project schedule. Expedited options may be available upon request.

Q2: What is the expected service life of your gabion cages?

A2: The service life varies based on the coating type and environmental conditions. Hot-dip galvanized gabions typically last 20-30 years. Galfan-coated gabions offer superior resistance, often exceeding 50 years. PVC-coated gabions, especially in aggressive or saline environments, can last 70 years or more.

Q3: Can your gabions be customized for specific project needs?

A3: Yes, absolutely. We specialize in customized solutions for gabion cages for sale. We can adjust dimensions (length, width, height), wire diameters, mesh apertures, and coating types to precisely match your project's unique specifications. Our engineering team is available for consultation.

Q4: What are your warranty commitments for gabion products?

A4: We offer a comprehensive warranty covering manufacturing defects for up to 5 years from the date of purchase. This ensures that our gabion box products meet the highest quality standards upon delivery and installation. Specific terms and conditions apply and are available upon request.

Q5: Do you provide technical support during project planning and installation?

A5: Yes, our commitment extends beyond product delivery. We provide expert technical consultation and support during the design and planning phases, as well as guidance for installation best practices. Our goal is to ensure the optimal performance and successful implementation of your gabion project.

Lead Time & Fulfillment Details

Our streamlined manufacturing processes and robust supply chain enable efficient order fulfillment. For standard gabion cages for sale, lead times typically range from 7 to 14 business days. Large or custom orders may require additional time, but clear timelines are communicated upfront. We maintain strategic inventory levels of raw materials to respond promptly to urgent client needs. Global shipping capabilities ensure timely delivery to project sites worldwide, with comprehensive logistics support.

Warranty Commitments

We stand behind the quality of our products. All gabion box materials are backed by a warranty against manufacturing defects for a period of up to 5 years. This commitment reflects our confidence in the durability and reliability of our gabions, manufactured under stringent quality control (ISO 9001 certified). We use only certified raw materials that meet international standards such as ASTM and EN.

Customer Support Information

Our dedicated customer support team is available to assist you from initial inquiry through project completion. Whether you need technical specifications, design assistance, order tracking, or after-sales support, our experts are ready to provide prompt and knowledgeable service. We offer multi-channel support including email, phone, and online consultation, ensuring you have access to the information and assistance you need when you need it.

Authoritative References and Citations

The information presented herein aligns with established industry standards and academic research concerning gabion technology.

- ASTM A975/A975M-11(2017) – Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses (Metallic-Coated Steel Wire or Metallic-Coated Steel Wire With PVC Coating)

- EN 10223-3:2013 – Steel wire and wire products for fencing and netting - Part 3: Steel wire mesh products for gabions and industrial uses

- EN 10244-2:2009 – Steel wire and wire products - Non-ferrous metallic coatings on steel wire - Part 2: Zinc or zinc alloy coatings

- International Organization for Standardization (ISO) 9001:2015 – Quality management systems – Requirements

- Federal Highway Administration (FHWA) – Gabions (FHWA-CFL/TD-00-004)

- Maccaferri – Gabions & Reno Mattresses: An Introduction. (Industry reference for gabion technology and applications).

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025