Aug . 15, 2024 04:57 Back to list

Exploring the Versatility and Applications of Welded Wire Mesh Sheets in Various Industries

Understanding Welded Mesh Sheets A Comprehensive Overview

Welded mesh sheets, often referred to as welded wire mesh, have become an essential element in various construction and industrial applications. Comprising a series of vertical and horizontal wires that are welded together at their intersections, these sheets offer significant strength and versatility, making them a favored choice among engineers and builders.

Composition and Manufacturing Process

Welded mesh sheets are typically made from high-quality steel wire, though they can also be produced using other materials such as stainless steel or galvanized steel for enhanced durability. The manufacturing process begins with the selection of wire rods which are then drawn into wire of desired diameters. The wires are arranged in a grid pattern and joined using a welding technique, which involves applying heat to fuse the wires at their intersections. This process not only ensures structural integrity but also provides uniform strength across the mesh.

Varieties and Specifications

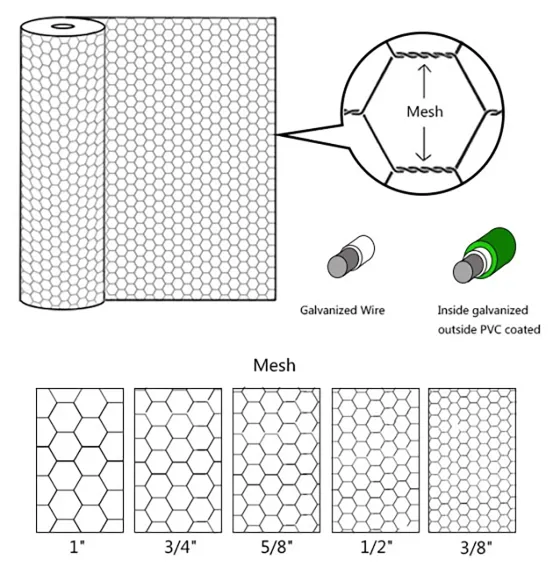

Welded mesh sheets come in various sizes and patterns, depending on the intended application. Common specifications include wire diameter, mesh spacing, and sheet dimensions. For example, sheets may range from lighter gauges for smaller projects, such as reinforcing decorative concrete, to heavy-duty mesh used in structural applications like road and bridge construction.

Additionally, welded mesh can be produced with different coatings, providing options that resist corrosion and improve longevity. Galvanized welded mesh sheets, for instance, are particularly popular in outdoor applications where exposure to moisture can lead to rust and deterioration.

Applications

weldmesh sheets

The versatility of welded mesh sheets prompts their use in a plethora of applications. In the construction industry, they are primarily used for concrete reinforcement, ensuring that structures have the necessary backbone to withstand stress and pressure. By embedding welded mesh into concrete, builders increase the tensile strength and offer resistance against cracking and shifting.

Beyond construction, welded mesh sheets find their application in various sectors such as agriculture, fencing, and industrial operations. In agriculture, they serve as support structures for plants, or as fencing to protect crops from animals. In industrial settings, they can be used to create safety barriers, and machine guards, or as storage solutions in warehouses.

Advantages

One of the main advantages of welded mesh sheets is their uniform strength, which eliminates weak points found in other reinforcement methods such as traditional rebar. The continuous, interconnected wire grid distributes loads evenly, providing enhanced stability. Furthermore, the convenience of handling and installation is a significant benefit; welded sheets are lightweight, easy to cut to size, and can be quickly incorporated into construction projects.

Additionally, the durability and longevity of welded mesh, especially when coated, reduce the need for frequent replacements, offering cost savings over time. The low maintenance requirement further enhances its attractiveness, as it can withstand harsh environmental conditions without significant wear.

Conclusion

In conclusion, welded mesh sheets are a fundamental component in modern construction and industrial applications. Their robust design, versatility, and cost-effectiveness make them an ideal choice for various needs, from concrete reinforcement to agricultural fencing. As technology advances, the production of welded mesh sheets continues to improve, offering even more options for builders and engineers aiming to achieve safety and efficiency in their projects. Whether you are a contractor, an architect, or a DIY enthusiast, understanding the benefits and applications of welded mesh sheets can enhance the quality and durability of your work.

-

Weather Resistance Properties of Quality Roofing Nails

NewsAug.01,2025

-

How Galvanised Iron Mesh Resists Corrosion in Harsh Environments

NewsAug.01,2025

-

Creative Landscaping Uses for PVC Coated Wire Mesh Panels

NewsAug.01,2025

-

Common Wire Nail Dimensions and Their Specific Applications

NewsAug.01,2025

-

Choosing the Right Welded Wire Sheets for Agricultural Fencing

NewsAug.01,2025

-

Anti - Climbing Features of Razor Wire Barriers

NewsAug.01,2025