Sep . 12, 2025 09:40 Back to list

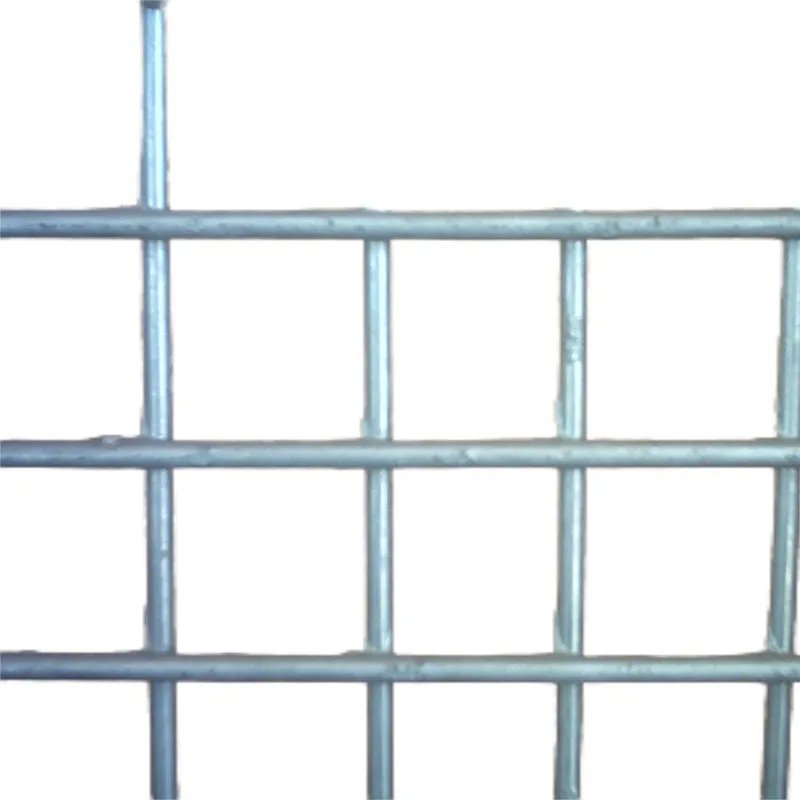

Durable Welded Mesh Panels | Strong, Versatile & Secure

Introduction to Advanced Welded Mesh Panel Solutions

In the realm of modern industrial and infrastructural development, the demand for robust, versatile, and high-performance material solutions is ever-increasing. Among these, welded mesh panels stand out as a fundamental component, offering unparalleled strength-to-weight ratios and design flexibility. These panels, also widely known as weldmesh sheets or mesh welded panels, are engineered by precisely welding individual wires at their intersections, creating a uniform and structurally sound grid. This meticulous fabrication process ensures consistent quality, making them ideal for a myriad of demanding applications across various sectors. Our focus today is on exploring the technical intricacies, expansive applications, and intrinsic advantages that make these panels indispensable in today's B2B landscape, from stringent safety barriers to critical structural reinforcements.

The evolution of material science and manufacturing precision has significantly enhanced the capabilities of these products. Modern production techniques allow for tailored specifications in terms of wire gauge, aperture size, material composition, and surface treatments, enabling engineers and project managers to specify solutions that perfectly align with specific operational requirements and environmental challenges. This adaptability underscores their value in projects where both performance and durability are paramount.

Industry Trends & Market Dynamics for Welded Mesh Panels

The market for welded mesh panels is experiencing dynamic shifts, driven by several key industry trends. Sustainability is a paramount concern, pushing manufacturers towards more eco-friendly production processes and recyclable materials. The adoption of advanced automation in welding and fabrication ensures higher precision, reduced waste, and increased production efficiency, directly impacting the cost-effectiveness and quality of the final product. There's a growing demand for specialized coatings, such as advanced galvanization and PVC coatings, to enhance corrosion resistance and extend service life in aggressive environments like coastal areas or chemical processing plants.

Furthermore, the construction sector's continued growth, particularly in infrastructure projects and commercial development, fuels the demand for high-strength steel welded mesh panels for concrete reinforcement, fencing, and safety enclosures. Security applications, ranging from perimeter fencing in industrial complexes to anti-climb barriers, increasingly rely on customized mesh configurations for enhanced protective capabilities. The integration of Building Information Modeling (BIM) in construction planning also necessitates standardized yet customizable mesh solutions that can be digitally modeled for precise integration.

Manufacturing Process & Technical Specifications

Detailed Manufacturing Process Flow of Welded Mesh Panels:

- Material Selection & Preparation: High-quality steel wire, typically low-carbon steel, galvanized steel, or stainless steel (e.g., AISI 304, 316), is selected based on application requirements. Wires undergo drawing processes to achieve precise diameters and specified tensile strengths, ensuring uniformity crucial for the subsequent welding process.

- Wire Straightening & Cutting: The drawn wires are fed into automated straightening machines to remove any bends or coils. Subsequently, they are cut to exact lengths for both longitudinal and transverse wires, preparing them for the welding grid.

- Automated Resistance Welding: This is the core manufacturing process. Longitudinal wires are fed continuously, while transverse wires are intermittently placed over them. High-precision resistance welding machines apply electric current and pressure at each intersection, fusing the wires together to form a robust and permanent joint. This computer-controlled process ensures uniform mesh aperture and superior weld integrity, critical for the structural performance of the welded mesh panels.

- Panel Cutting & Trimming: The continuous welded mesh is then cut into individual panels according to specified dimensions. Edge trimming ensures clean, safe borders, removing any excess wire.

- Surface Treatment (If Applicable): For enhanced durability and corrosion resistance, panels may undergo various surface treatments. Common treatments include hot-dip galvanizing (conforming to ISO 1461 or ASTM A123), electro-galvanizing, or PVC coating. These processes significantly extend the service life, especially in outdoor or corrosive environments.

- Quality Control & Testing: Each batch of welded mesh panels undergoes rigorous quality control. This includes visual inspection for defects, dimensional checks of mesh aperture and panel size, and mechanical tests such as tensile strength tests (e.g., ASTM A740), weld shear strength tests, and coating adherence tests. Adherence to international standards like ISO 9001 for quality management and ASTM F567 for chain link fencing ensures product reliability. Expected service life for properly galvanized panels can exceed 20-30 years, depending on environmental conditions.

Typical Technical Specifications for Welded Mesh Panels

Understanding the precise technical parameters is crucial for specifying the correct welded mesh panels for any given project. Below is a table outlining common specifications.

| Parameter | Description | Typical Range/Value | Relevant Standard |

|---|---|---|---|

| Material | High-quality low-carbon steel, galvanized steel, stainless steel (304, 316) | Q195, Q235, AISI 304/316 | ASTM A82, A185 |

| Wire Diameter | Gauge of individual wires | 2.0 mm - 6.0 mm (0.078 in - 0.236 in) | EN 10223-4 |

| Mesh Aperture (Opening) | Distance between adjacent wires (center-to-center or clear opening) | 25x25 mm to 200x200 mm (1x1 in to 8x8 in) | ISO 9044 |

| Panel Size | Overall dimensions of the mesh panel | 1.0m x 2.0m to 2.5m x 6.0m (custom sizes available) | Custom, Project-specific |

| Tensile Strength | Maximum stress a wire can withstand before breaking | 450-550 N/mm² (for steel wire) | ASTM A740 |

| Weld Shear Strength | Force required to break a weld joint | Varies with wire diameter (e.g., >2.5 kN for 4mm wire) | ASTM A185 |

| Surface Treatment | Coating applied for corrosion resistance and aesthetics | Hot-dip galvanized, Electro-galvanized, PVC Coated | ISO 1461, ASTM A123 |

Diverse Application Scenarios & Technical Advantages

The versatility of welded mesh panels makes them indispensable across a multitude of industries. Their inherent strength, uniform structure, and customizable properties cater to a broad spectrum of functional requirements.

- Construction Industry: Used extensively for concrete reinforcement (reducing crack formation and enhancing structural integrity), walkways, safety barriers, stair treads, and gabion baskets for retaining walls and erosion control.

- Security & Fencing: High-security perimeter fencing, machine guards in manufacturing facilities, window guards, and anti-climb barriers. The rigid structure of mesh welded panels provides robust protection.

- Agriculture & Horticulture: Animal enclosures, poultry cages, trellises for climbing plants, crop protection, and general farm fencing.

- Industrial & Commercial: Storage shelves, partitioning, racking systems, ventilation screens, and infill panels for gates and balustrades.

- Water Supply & Drainage: Filter screens, trash racks, and grates in water treatment plants and sewage systems, benefiting from excellent corrosion resistance when galvanized or stainless steel mesh is utilized.

- Petrochemical & Metallurgy: Platforms, grating, and safety enclosures where robust, corrosion-resistant materials are critical. Stainless steel welded mesh panels offer superior performance in these harsh environments, demonstrating advantages in energy saving through optimized airflow and reduced maintenance.

Key Technical Advantages:

- Superior Strength & Durability: The precision welding at each intersection creates a strong, rigid panel capable of withstanding significant loads and impacts, far surpassing the strength of woven mesh.

- Uniform Mesh & Aesthetics: Consistent wire spacing and firm welds ensure a uniform mesh pattern, contributing to both structural integrity and a clean, professional appearance.

- Corrosion Resistance: When hot-dip galvanized or manufactured from stainless steel, these panels offer exceptional resistance to rust and environmental degradation, significantly extending service life and reducing lifecycle costs.

- Versatility & Customization: Available in a wide range of wire diameters, mesh sizes, and panel dimensions, with options for various materials and coatings, allowing for precise specification to meet unique project requirements.

- Ease of Installation: The rigidity and flat nature of welded mesh panels make them easy to handle, cut, and install, reducing labor time and associated costs during project execution.

- Cost-Effectiveness: Their long service life, low maintenance requirements, and efficient manufacturing process translate into a highly cost-effective solution over the lifespan of a project.

Application Case Study: Industrial Petrochemical Facility

A major petrochemical complex required robust, corrosion-resistant fencing and grating for its hazardous chemical storage areas and access platforms. The environment demanded materials capable of withstanding constant exposure to corrosive agents and extreme temperatures, while also ensuring high-level security.

Solution Implemented: High-grade AISI 316 stainless steel welded mesh panels, with a 50x50mm mesh opening and 4mm wire diameter, were chosen for both the perimeter security fencing and the grating on elevated platforms. The specific alloy provided superior resistance to chloride-induced corrosion and high-temperature oxidation. The panels were custom-fabricated to precise dimensions, allowing for seamless integration with the existing structural framework.

Results: The stainless steel mesh welded panels provided exceptional durability and safety. Their inherent strength deterred unauthorized access, and the corrosion resistance significantly reduced maintenance overheads compared to traditional coated steel options. The open mesh design facilitated natural ventilation, contributing to safety by preventing the accumulation of volatile gases. The project demonstrated the critical role of material selection and technical specifications in achieving long-term operational efficiency and safety in challenging industrial environments.

Vendor Comparison & Customized Solutions

Selecting the Right Vendor for Welded Mesh Panels

Choosing the appropriate vendor for welded mesh panels is critical for project success, impacting product quality, lead times, and overall cost-efficiency. Key factors to consider include:

- Quality Certifications: Ensure the vendor adheres to international quality standards such as ISO 9001, and that their products meet relevant material specifications (e.g., ASTM, EN standards).

- Manufacturing Capabilities: Assess their capacity for high-volume production, precision welding, and the ability to handle diverse wire gauges and mesh configurations.

- Customization Expertise: A strong vendor should offer extensive customization options, including bespoke panel sizes, specific wire diameters, unique mesh patterns, and a variety of surface treatments.

- Experience and Reputation: Look for vendors with a proven track record in the industry, positive customer feedback, and a portfolio of successful projects demonstrating their ability to deliver complex solutions.

- Technical Support & After-Sales Service: Availability of technical support, engineering consultation, and clear warranty policies are vital for long-term project viability.

Tailored Customized Solutions

Recognizing that no two projects are identical, leading manufacturers of welded mesh panels offer comprehensive customized solutions to meet precise client specifications. This capability is paramount for complex engineering projects where off-the-shelf products may not suffice.

Customization options for weldmesh sheets include:

- Exact Panel Dimensions: Panels can be fabricated to specific length and width requirements, minimizing waste and reducing on-site cutting.

- Varied Wire Gauges: From fine wires for filtration or small animal enclosures to heavy-duty wires for structural applications and high-security fencing.

- Specific Mesh Apertures: Custom mesh openings to control flow, provide specific levels of visibility, or meet precise safety regulations.

- Material Selection: Choice of galvanized steel, stainless steel (various grades), or even plain steel for subsequent painting or coating by the client.

- Advanced Coatings: PVC coating in various colors for aesthetic appeal or enhanced chemical resistance, often seen in architectural applications or highly corrosive industrial settings.

- Post-fabrication Treatments: Bending, rolling, or shaping the panels to fit non-flat surfaces or integrate into complex designs.

By offering such extensive customization, manufacturers empower engineers and procurement specialists to design and implement solutions that are perfectly optimized for performance, longevity, and cost-efficiency.

Commitment to Quality, Transparency, and Support

Frequently Asked Questions (FAQ)

Q1: What is the primary difference between welded mesh and woven mesh?

A1: Welded mesh panels have wires resistance-welded at each intersection, creating a rigid and stronger structure with fixed apertures. Woven mesh, conversely, is made by weaving wires over and under each other, which allows for more flexibility but generally lower rigidity compared to weldmesh sheets.

Q2: How do I choose the correct wire diameter and mesh size for my project?

A2: This depends heavily on the application. For structural reinforcement or high-security fencing, thicker wire diameters and smaller mesh openings are generally preferred. For filtration or lightweight enclosures, finer wires and larger meshes might be suitable. We recommend consulting our technical sales team for precise recommendations based on load requirements, environmental factors, and regulatory standards.

Q3: What surface treatments are available to prevent corrosion?

A3: The most common and effective treatments are hot-dip galvanizing (for superior outdoor protection), electro-galvanizing (for a smoother finish and moderate protection), and PVC coating (for enhanced aesthetics, chemical resistance, and additional weatherproofing). Stainless steel variants offer inherent corrosion resistance.

Lead Time & Fulfillment Details

Our standard lead time for stock welded mesh panels typically ranges from 7-14 business days, depending on order volume and specific product type. For custom orders, lead times may extend to 3-5 weeks, factoring in material sourcing, custom fabrication, and specialized surface treatments. We maintain robust inventory levels and efficient production lines to ensure timely delivery. Urgent orders can often be accommodated through expedited manufacturing and shipping options, subject to project specifics and prior arrangement with our sales team. Our logistics partners are carefully selected for their reliability and ability to handle large or specialized shipments, ensuring your mesh welded panels arrive safely and on schedule.

Warranty Commitments

We stand behind the quality of our welded mesh panels with a comprehensive warranty against manufacturing defects. All products are guaranteed to meet the specified technical parameters and industry standards (e.g., ISO, ASTM) at the time of delivery. The duration of the warranty varies depending on the product type and surface treatment, typically ranging from 5 to 10 years for hot-dip galvanized and stainless steel products under normal usage conditions. Detailed warranty terms and conditions are provided with each quotation and order confirmation, ensuring full transparency and peace of mind for our clients.

Dedicated Customer Support

Our commitment extends beyond product delivery. We offer dedicated technical support and after-sales service to assist with any queries regarding installation, maintenance, or product performance. Our team of experienced engineers and customer service representatives is available via phone, email, and online portal to provide expert advice and prompt assistance. We believe in building lasting partnerships, ensuring that our clients receive continuous support throughout the lifecycle of their projects involving our mesh welded panels. For immediate assistance or to discuss your specific project needs, please visit our contact page or reach out directly to our support team.

Conclusion

In conclusion, welded mesh panels are a cornerstone material in modern industrial and construction applications, offering an unmatched combination of strength, versatility, and durability. From their meticulously controlled manufacturing process, adhering to stringent international standards, to their broad spectrum of applications across petrochemical, metallurgy, construction, and security sectors, these panels deliver consistent performance. The ability to customize dimensions, materials, and finishes ensures that specific project requirements are not only met but often exceeded, driving efficiency and enhancing safety. As industries evolve, the demand for reliable, high-performance, and sustainable materials will only grow, solidifying the position of weldmesh sheets as a critical component in future development.

References

- ASTM International. "Standard Specification for Welded Steel Wire Fabric, Plain, for Concrete Reinforcement." ASTM A185/A185M.

- International Organization for Standardization. "Hot dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods." ISO 1461:2022.

- Eurocode 2: Design of concrete structures — Part 1-1: General rules and rules for buildings. EN 1992-1-1:2004.

- American Iron and Steel Institute. "Steel Wire Handbook."

- International Organization for Standardization. "Wire screens and plate screens for industrial purposes — Nominal sizes of apertures and wire diameters." ISO 9044:2009.

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025